The Regulatory Framework: Understanding OSHA and ASME Crane Safety Standards

Understanding crane safety standards is crucial for preventing accidents on job sites. These rules, set by regulatory bodies like OSHA and industry groups like ASME, cover hazard prevention, personnel qualifications, inspections, and ground conditions. Operating powerful machines like cranes carries inherent risks, and following strict safety standards is not just about compliance—it’s about saving lives. This guide will clarify the key regulations that form the backbone of crane safety in the United States.

Crane safety standards terms made easy:

This section covers the primary governing bodies and the specific regulations that form the backbone of crane safety in the United States, from federal law to industry-developed technical standards.

Key OSHA Crane Safety Standards for Every Industry

The Occupational Safety and Health Administration (OSHA) is the primary U.S. regulatory body for workplace safety. Our commitment to crane safety standards begins with adhering to these federal requirements. OSHA’s “General Duty Clause” requires employers to provide a workplace free from recognized hazards, allowing it to enforce safety practices even without a specific standard, often by referencing industry consensus standards like ASME.

OSHA crane safety standards are categorized by industry:

- Construction Industry (29 CFR 1926 Subpart CC): This is the most comprehensive set of crane regulations, applying to power-operated equipment in construction with a capacity over 2,000 lbs. It addresses operator qualification, assembly/disassembly, inspections, and power line safety. For a detailed guide, see An overview of the Cranes and Derricks in Construction Standard.

- General Industry (29 CFR 1910.179): This standard focuses on overhead and gantry cranes in settings like manufacturing and warehousing, detailing requirements for design, operation, and inspection.

- Maritime Standards (29 CFR 1915, 1917, 1918): These regulations address crane safety in specific maritime environments, including shipyards, marine terminals, and longshoring.

- Gear Certification Standards (29 CFR 1919): This part deals with the certification of cargo handling gear, including tests and inspections.

Beyond federal OSHA, 29 OSHA-approved State Plans operate their own safety programs, which can be more stringent. We remain vigilant in understanding local crane safety standards in areas like Pennsylvania, Ohio, West Virginia, and Maryland. For more information on operational safety, visit Crane Operation Safety Standards.

How ASME B30 Standards Contribute to Crane Safety

While OSHA sets the legal framework, the American Society of Mechanical Engineers (ASME) develops comprehensive, industry-driven crane safety standards. The ASME B30 Safety Standard is a suite of over 30 volumes providing detailed guidelines for various lifting and rigging equipment.

These are “consensus standards” accredited by the American National Standards Institute (ANSI). OSHA often incorporates them by reference, making them legally enforceable. While OSHA’s “shall” is mandatory, ASME’s “should” (recommended practices) often become de facto requirements for safe operation.

The ASME B30 series includes:

- ASME B30.5 – Mobile and Locomotive Cranes: A critical standard for mobile cranes, covering construction, inspection, maintenance, and operation.

- ASME B30.9 – Slings: Provides detailed requirements for the construction, inspection, and use of all types of slings.

- ASME B30.10 – Hooks: Addresses hook inspection, maintenance, and criteria for removal from service.

- ASME B30.16 – Overhead Hoists (Underhung): Provides safety standards for overhead hoists.

- ASME B30.20 – Below-the-Hook Lifting Devices: Covers specialized lifters that attach to a crane’s hook.

- ASME B30.26 – Rigging Hardware: Specifies requirements for shackles, eyebolts, and other essential hardware.

Our adherence to ASME B30 standards ensures regulatory compliance and improves workplace safety, minimizes downtime, and protects equipment. Learn more from The American Society of Mechanical Engineers (ASME).

Proactive Safety on Site: Inspections, Hazard Prevention, and Ground Conditions

Beyond regulations, on-site diligence is crucial. This involves rigorous equipment checks, identifying and mitigating common hazards, and ensuring the ground can support the massive forces involved in a lift.

Crane Inspection, Testing, and Maintenance Requirements

Regular inspection, testing, and maintenance form the foundation of reliable crane operations, helping to spot potential problems before they become dangerous. Our comprehensive inspection strategy includes:

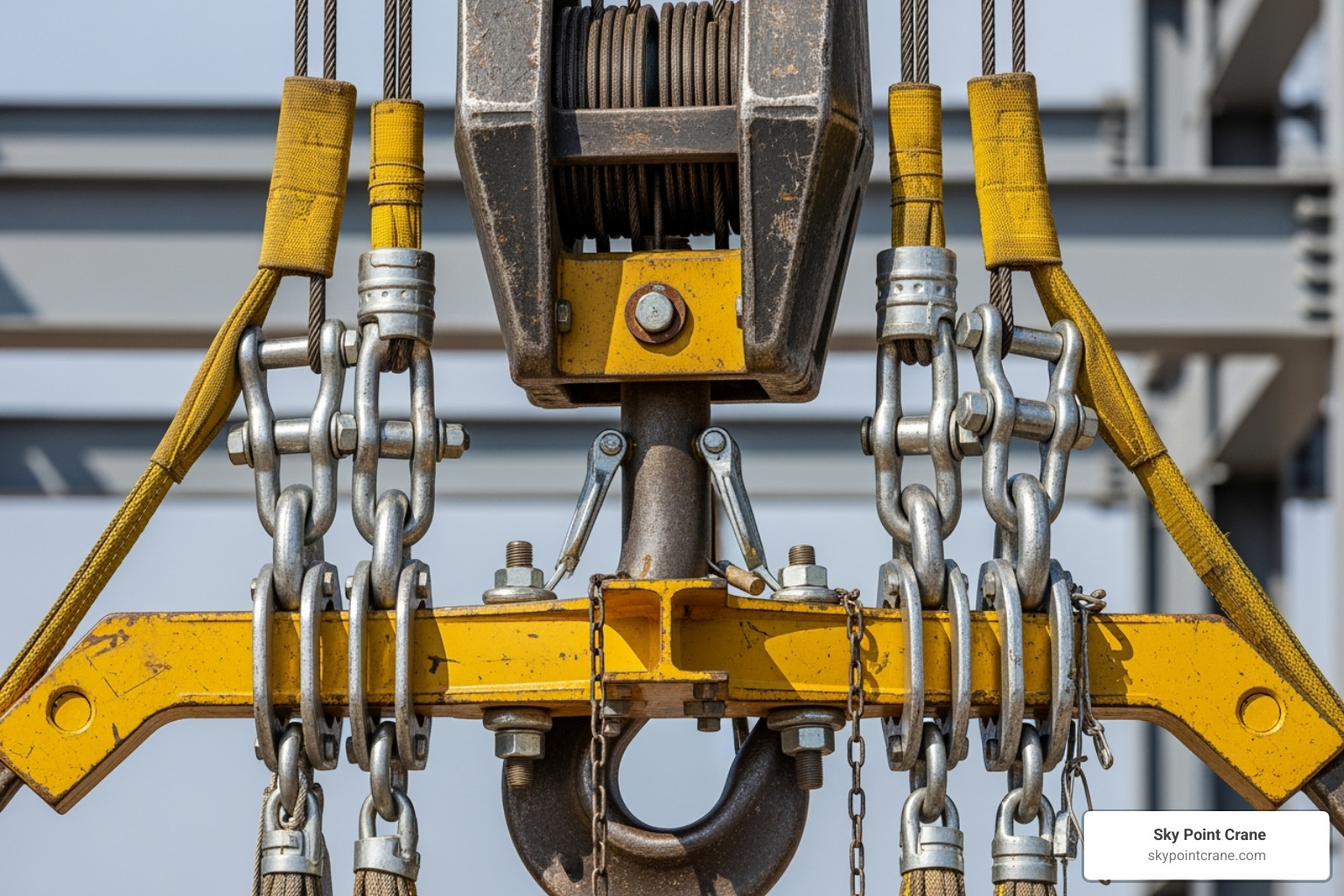

- Daily Pre-Shift Inspections: Before each shift, operators conduct thorough checks of all critical systems, including controls, operating mechanisms, hydraulic systems, hooks, wire ropes, brakes, and warning devices.

- Frequent & Periodic Inspections: These checks, ranging from daily to monthly (frequent) and one to twelve months (periodic), examine operating mechanisms and structural components more deeply to catch issues early.

- Annual Comprehensive Inspections: All cranes and derricks must be inspected and proof load tested annually by an accredited crane certifier to ensure they meet all safety and performance specifications.

- Load Testing Procedures: OSHA requires load testing for new or modified cranes. We test at 100% of the rated capacity (never exceeding 125%) to verify full functionality under stress.

Our maintenance programs follow manufacturer recommendations, and every inspection, test, and repair is carefully documented. This record-keeping helps us track each crane’s safety history and continuously improve our protocols. For more details, see Crane Safety Protocols.

Common Crane Hazards and Prevention Strategies

Understanding common hazards and implementing solid prevention strategies are key to managing risks. Our commitment to crane safety standards means addressing these dangers head-on.

- Power line contact: Prevented by maintaining minimum clearance distances, using trained spotters, and ensuring clear communication.

- Overloading: Avoided by strictly following the crane’s load charts and verifying all load weights.

- Improperly supporting equipment: Ensured by fully extending outriggers and using appropriate blocking or mats to distribute loads.

- Inadequate ground preparation: Addressed through thorough ground assessments to ensure the surface is firm and stable.

- Poor visibility: Mitigated by using qualified signal persons and maintaining clear sightlines and communication.

- Mechanical failures: Prevented through our rigorous inspection schedule and proactive maintenance program.

- Dropped loads: Avoided by using proper rigging techniques and hardware that meets ASME B30.26 standards.

Understanding OSHA regulations and having proper communication tools are vital for safe crane operations. Understanding OSHA regulations and having the right communication tools are vital for ensuring safe crane operation. Additional insights can be found at Crane and Rigging Safety.

The Critical Role of Ground Conditions

The ground beneath a crane is its foundation, and its stability is critical. Inadequate ground conditions are a leading cause of crane overturning accidents. As part of our crane safety standards, we take ground assessment very seriously.

Per OSHA 1926.1402, the ground must be firm, drained, and graded to support the crane. The controlling entity (e.g., general contractor) is responsible for preparing the ground and informing the crane operator of any known subsurface hazards like voids or utilities.

As the crane operating company, if our operator or director determines conditions are unsafe, we will not proceed until the necessary preparations are made. Safety always takes priority. Supporting materials like outrigger pads, crane mats, and cribbing are used to distribute the load over a wider area, ensuring a stable foundation for the lift.

By carefully assessing ground conditions and using proper supporting materials, we protect against overturning and other ground-related hazards. More details can be found at OSHA’s standard for ground condition assessment.

The Human Element: Personnel Qualifications and Responsibilities

A crane is only as safe as the team operating it. This section details the essential qualifications and duties for every person involved in a lifting operation, from the operator in the cab to the crew on the ground.

The Crane Operator: Certification and Competency

The crane operator is central to a safe lift. Their skill, judgment, and commitment to crane safety standards are paramount. At Sky Point Crane, we ensure our operators are highly qualified, certified, and masters of their craft.

An operator’s duties include performing pre-operation checks, strictly following load charts, ensuring safe load handling, maintaining situational awareness of the work area, communicating clearly with the ground crew, and never leaving the controls while a load is suspended.

Certification Requirements: OSHA 1926 Subpart CC mandates that construction crane operators be certified or qualified for the specific type of crane they operate. This legal requirement ensures operators have the necessary knowledge and skills. The National Commission for the Certification of Crane Operators (NCCCO) is a leading, nationally recognized certification body. Our deep commitment to crane safety standards means every one of our operators is NCCCO Certified, demonstrating their proficiency in safe operating practices. True competency also involves ongoing, site-specific training, which we prioritize for our team. To learn more about why certified operators are so vital, check out NCCCO Certified Crane Operators, and you can explore the NCCCO organization itself at National Commission for the Certification of Crane Operators (NCCCO).

The Ground Crew: Riggers, Signal Persons, and Lift Directors

A safe lift is a team effort, and the ground crew plays a vital role in ensuring every lift is planned, rigged, and guided safely. Our dedication to the highest crane safety standards extends to every member of this team.

- Lift Director: This individual holds the ultimate authority for the lifting operation. They are responsible for ensuring everyone is qualified, the lift plan is followed, and all safety precautions are in place.

- Qualified Riggers: These trained and experienced professionals are responsible for selecting, inspecting, and using rigging equipment to safely attach and detach the load. They understand load dynamics, center of gravity, and sling angles to prevent load swinging or slipping. We employ only certified riggers to prevent catastrophic failures from improper rigging. Learn more at The Importance of Certified Riggers in Today’s Construction Industry.

- Qualified Signal Person: When the operator’s view is obstructed, the signal person acts as their “eyes” and “ears.” They must be proficient in standard hand signals or radio communication, understand crane operations and limitations, and maintain a clear line of sight. We adhere to strict communication protocols, using standard signals as outlined by OSHA, to prevent misunderstandings. Explore this role further here: Why Rigging and Signal Persons Are Essential in Crane Operations.

By ensuring every team member is qualified and understands their role, we build a cohesive and safe lifting environment, consistently upholding the highest crane safety standards.

Frequently Asked Questions about Crane Safety Standards

We understand that crane safety standards can be complex. To help clarify, here are straightforward answers to some of the most common questions we hear.

What is the difference between OSHA regulations and ASME standards?

Think of the distinction this way: OSHA (Occupational Safety and Health Administration) sets the legally binding safety rules for all U.S. workplaces. Compliance with OSHA regulations is mandatory by law.

ASME (American Society of Mechanical Engineers) is an organization of industry experts that develops detailed, technical “best practice” standards for how to design, operate, and maintain equipment like cranes. While ASME standards are not laws themselves, OSHA often incorporates them into its regulations by reference, which makes them legally enforceable. In short, OSHA creates the law, and ASME provides the technical “how-to” that often becomes part of the law.

Is crane operator certification required in the United States?

Yes. For most cranes used in construction, OSHA’s 29 CFR 1926 Subpart CC mandates that operators be certified or qualified. This is a legal requirement designed to ensure the person at the controls has the proven knowledge and skills to operate the machinery safely. Certification, typically from an accredited body like the National Commission for the Certification of Crane Operators (NCCCO), involves passing both written and practical exams. At Sky Point Crane, all our operators are NCCCO Certified.

Who is responsible for ensuring the ground is safe for a crane setup?

This is a shared responsibility. According to OSHA 29 CFR 1926.1402, the “controlling entity” (usually the general contractor or site owner) has the primary responsibility to ensure the ground is properly prepared and to inform the crane user of any known underground hazards.

However, the crane operating company and its operator must also assess the conditions. If the ground is deemed unsafe, the crane operator has the authority and responsibility to refuse to assemble or operate the crane until the conditions are corrected. Safety always takes precedence over proceeding with a lift.

Conclusion

Adherence to crane safety standards boils down to four key pillars: rigorous regulations, well-maintained equipment, competent personnel, and meticulous site preparation. As technology and practices evolve, our commitment to safety remains constant, because we believe safety is not a checklist, but a culture.

From OSHA’s legal mandates to ASME’s technical specifications, these crane safety standards form the foundation of our work. Our team—from our NCCCO certified operators to our skilled riggers and ground crews—doesn’t just follow the rules; they embody a culture of safety. This proactive approach protects our crew, our clients, and the public.

At Sky Point Crane, we always aim higher than “good enough.” We leverage tools like 3D Lift Planning to mitigate risks before they arise, providing safe and precise crane services 24/7 across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland.

Smart planning is where safety truly begins. Explore our 3D Lift Planning services to see how we integrate technology and expertise to ensure every lift is executed with the highest degree of care and professionalism.