Essential Guide to Self-Erecting Tower Crane Repairs

When your project demands constant uptime, unexpected breakdowns are a significant concern. Understanding self erect tower crane repairs is crucial for maintaining operational efficiency and ensuring safety compliance on any job site.

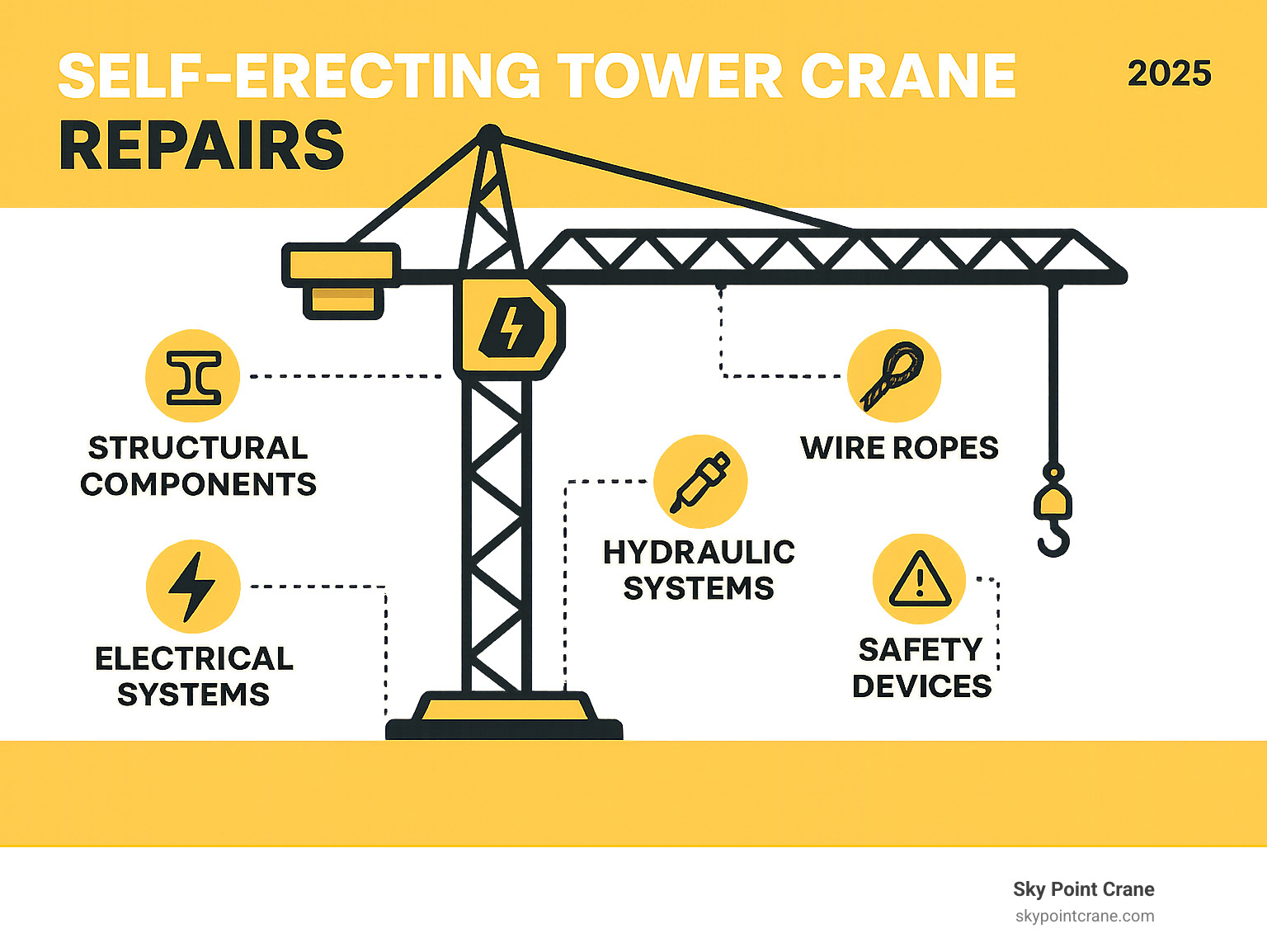

Here’s a quick overview of why and where these repairs are typically needed:

- Preventing Costly Downtime: Addressing issues promptly keeps your projects on schedule.

- Ensuring Safety: Regular repairs mitigate risks from wear and tear on critical parts.

- Common Repair Areas Include:

- Wire ropes (fraying, corrosion)

- Brake pads (excessive wear)

- Hydraulic systems (leaks, fluid issues)

- Electrical systems (faulty connections, overheating)

- Structural components (fatigue, damage)

- Safety devices (malfunctioning limit switches, overload indicators)

This guide will help you steer the essential steps to address these issues and keep your crane performing optimally.

Dave Brocious has over 30 years of experience in the industry, building effective teams and solving complex problems for customers. His work at Sky Point Crane focuses on delivering unique solutions and value, including expert self erect tower crane repairs.

Simple self erect tower crane repairs glossary:

Spotting the Signs: When Does Your Crane Need Repair?

A self-erecting tower crane often signals a problem before a major breakdown occurs. Catching these signs early prevents costly downtime and ensures job site safety. Operator feedback is invaluable, as they are the first to notice issues. Prompt action is the first step in effective self erect tower crane repairs.

Be alert for these common warning signs:

- Unusual Noises: Creaks, grinding, or clunking from the machinery, slewing ring, or hoist can indicate worn or loose parts.

- Performance Degradation: Sluggish or jerky movements, reduced lifting capacity, or slower operation often point to hydraulic, electrical, or mechanical problems.

- Fluid Leaks: Puddles of hydraulic fluid, oil, or grease are clear signs of failing seals, cracked hoses, or damaged components.

- Warning Lights or Alarms: Onboard control systems will alert you to sensor, limit switch, or system failures. Never ignore these warnings.

- Visible Wear and Tear: Regularly look for excessive wear, corrosion on the structure, or physical damage to the jib, mast, or counterweights.

Common Issues Requiring Self Erect Tower Crane Repairs

Knowing common failure points helps with proactive maintenance. Here are frequent issues that require expert self erect tower crane repairs:

- Structural Fatigue and Damage: Heavy lifting can cause fatigue cracks in welds or bends in the jib or mast. Hidden damage from collisions may require special testing to detect.

- Wire Rope Fraying or Corrosion: Frayed, kinked, or corroded wire ropes have compromised strength and pose a major safety risk. Their condition directly impacts lifting safety.

- Brake Pad Wear: Worn brake pads reduce stopping power and the ability to hold loads securely, leading to performance and safety issues.

- Hydraulic System Failure: Leaks, contaminated fluid, or failing pumps and valves can cause a loss of power, slow movement, or complete operational failure.

- Electrical Faults: Faulty wiring, bad connections, failed sensors, or overheating motors can cause erratic behavior or a total shutdown.

- Limit Switch Malfunction: These vital safety devices prevent the crane from operating outside its limits. A failure can lead to accidents or equipment damage.

Regular inspections, as detailed in our Crane Operation Safety Standards, are the best defense against these problems.

The Step-by-Step Guide to Self Erect Tower Crane Repairs

When your self-erecting tower crane needs attention, a clear, systematic repair plan is essential to get it back in service safely and efficiently. At Sky Point Crane, our process ensures a lasting solution, whether the repair is on-site or at our facility. Our comprehensive Crane Services cover every stage of the repair.

Step 1: Diagnosis and Inspection

The most critical phase of any self erect tower crane repair is a thorough diagnosis. Our technicians begin with a detailed visual inspection to spot obvious issues like cracks, leaks, or frayed ropes. This is followed by functional testing to observe the crane’s behavior, listen for unusual noises, and verify safety device operation. For suspected structural issues, we employ Non-Destructive Testing (NDT) to find hidden cracks or internal damage. We also conduct detailed electrical and hydraulic system checks, inspecting everything from control panels and wiring to pumps and hoses. Throughout this process, we strictly adhere to manufacturer guidelines, like those for the Self-Erecting Crane, using specialized diagnostic tools to pinpoint the root cause of the problem.

Step 2: Executing the Repair

Once the issue is diagnosed, our factory-trained technicians perform the repair with precision and a strict focus on safety. We begin by isolating the affected system using lockout/tagout procedures to prevent accidental activation. We prioritize genuine OEM (Original Equipment Manufacturer) parts for optimal fit and performance, but can also source high-quality aftermarket parts as a reliable, cost-effective alternative. Our expertise covers:

- Mechanical Repairs: Replacing worn gears and bearings or performing complex structural welding and fabrication.

- Electrical Repairs: Fixing faulty wiring, replacing damaged sensors, and servicing control boards and motors.

- Hydraulic Repairs: Replacing seals and hoses, repairing pumps and cylinders, and servicing control valves to restore lifting power.

Many repairs can be performed on-site to minimize downtime. Our 24 Hour Crane Service ensures we can respond quickly. For major overhauls, we can transport the crane or its components to our specialized maintenance facility.

Step 3: Documenting Self Erect Tower Crane Repairs for Compliance

A repair is not complete until it is properly documented. This step is crucial for compliance, safety audits, and future maintenance planning. We maintain detailed service logs and repair reports for every job, recording the issue, the work performed, and the parts used. This creates a comprehensive maintenance history for your crane, which is invaluable for future diagnostics, preventative maintenance planning, and increasing the asset’s resale value. Proper documentation is vital for meeting OSHA standards and demonstrates due diligence in maintaining your equipment, a key aspect of Understanding the Importance of Crane Safety in Modern Construction.

Safety First: Essential Precautions During Repairs

Safety is the core of our operations, especially during self erect tower crane repairs. Working on these powerful machines involves unique risks, which is why we follow strict safety protocols to protect our technicians, your team, and the equipment.

Key safety precautions for every repair include:

- Lockout/Tagout Procedures: Before any work, the crane is completely de-energized and locked out to prevent accidental movement or electrical shock.

- Personal Protective Equipment (PPE): Our technicians always wear appropriate PPE, including hard hats, safety glasses, gloves, and steel-toe boots.

- Fall Protection: When working at height, full-body harnesses, lanyards, and other fall arrest systems are mandatory.

- Site Security: The repair area is clearly marked and barricaded to prevent unauthorized access, creating a safe work zone.

- Hazard Assessment: We identify and mitigate potential risks, such as falling objects or electrical hazards, before work begins.

Only qualified, factory-trained technicians handle our repairs. Their expertise is vital, as improper work can create new dangers. We maintain clear communication with your site management throughout the process. By adhering to these precautions, we ensure every job is completed safely and effectively. Learn more in our Crane Safety Protocols.

Preventative Maintenance: The Best Repair is No Repair

While we are experts in self erect tower crane repairs, our primary goal is to help you avoid them. Preventative maintenance (PM) is a proactive approach to keep your crane performing at its best, ensuring longevity, safety, and compliance. Regular PM reduces costly downtime, extends the life of expensive components, and keeps your projects on schedule.

Key areas that require regular attention include wire ropes, brakes, the slewing ring, hydraulic and electrical systems, and structural components. Following a consistent maintenance schedule is the best way to catch minor issues before they become major problems.

Here is a typical preventative maintenance checklist:

-

Daily Maintenance (Operator):

- Visual inspection for damage, leaks, or loose parts.

- Check fluid levels.

- Test controls, limit switches, and emergency stops.

- Confirm alarms are working.

-

Weekly Maintenance:

- Thorough inspection of structural components, wire ropes, and hydraulic hoses.

- Check electrical connections for tightness.

- Lubricate all grease points per manufacturer schedule.

- Check brake function.

-

Monthly/Quarterly Maintenance (Technician):

- Comprehensive structural, hydraulic, and electrical system inspection.

- Test all safety devices under controlled conditions.

- Inspect slewing ring for play and smooth operation.

- Conduct fluid analysis for hydraulic and gear oils.

- Check fastener torque.

- Our preventative maintenance inspections are performed every three months (or 250 hours) to meet regulatory standards.

-

Major Periodic Inspections:

- Five-Year Block and Ball Inspections: A detailed tear-down and rebuild of load and hook blocks.

- Ten-Year Boom Assembly Inspections: A complete structural tear-down and inspection of the boom assembly (required every 10 years or 10,000 hours).

Adhering to these PM schedules ensures your self-erecting tower crane remains a reliable and safe asset for years to come.

Making the Call: Repair vs. Replacement

Deciding whether to repair a part or replace an entire component on your self-erecting tower crane is a critical decision that balances cost, project timelines, and safety. At Sky Point Crane, we help you make the smartest choice for your operation.

Several factors influence whether a repair or replacement is more cost-effective:

- Cost Analysis: We look beyond the initial price, considering the total cost including potential downtime. A cheap repair that leads to more downtime can be more expensive in the long run.

- Component Availability: If a new part has a long lead time, a timely repair may be the best option to keep your project on schedule. Conversely, if a part is readily available, replacement might be faster.

- Crane Age and Condition: For an older crane with widespread wear, investing in a major repair might not be a wise long-term solution. For a newer crane, a quality self erect tower crane repair can effectively extend its service life.

- Downtime Cost: Every hour a crane is idle costs money in lost productivity and potential project delays. Sometimes, a faster replacement is worth the higher part cost to minimize this impact.

- Safety Implications: For critical load-bearing or safety components (like brakes or wire ropes), replacement is often the safest choice, eliminating any doubt about the part’s integrity.

- Long-Term Reliability: Our goal is a lasting solution. A repair that is likely to fail again may be less reliable than a full replacement, which often comes with a warranty.

Consider this example for a hydraulic pump:

| Factor | Repair Hydraulic Pump (e.g., seal replacement, minor valve work) | Replace Hydraulic Pump (with new OEM unit) |

|---|---|---|

| Initial Cost | Lower (labor + seals/minor parts) | Higher (new pump unit + labor) |

| Downtime | Moderate (diagnosis, disassembly, repair, reassembly, testing) | Potentially lower (if new unit is in stock) |

| Reliability | Depends on severity of original issue; potential for recurring problem if internal wear is significant | High (new unit, full warranty) |

| Lifespan | Extended, but not necessarily to original new pump lifespan | Full new component lifespan |

| Warranty | Often limited to repair work, not pump itself | Full manufacturer’s warranty |

Our team provides transparent assessments to help you make the most cost-effective and safest choice for your self erect tower crane repairs.

Frequently Asked Questions about Self-Erecting Tower Crane Repairs

We understand you have questions about self erect tower crane repairs and maintenance. Here are concise answers to some of the most common inquiries we receive.

What are the most critical components to inspect regularly?

The most critical components are wire ropes (for fraying/corrosion), the slewing ring (for smooth rotation), brakes (for wear), hydraulic systems (for leaks), and all safety devices (limit switches, emergency stops). We also closely inspect load-bearing structures, welds, and electrical systems.

How often should a self-erecting tower crane be professionally serviced?

Follow the manufacturer’s recommendations, which typically require professional inspections every three months (or 250 hours) and a comprehensive annual inspection. Major structural inspections are also required at 5 and 10-year intervals (or 10,000 hours for the boom).

Can minor repairs be handled by on-site staff?

While on-site staff can handle daily checks and minor tasks like lubrication, most self erect tower crane repairs should be left to certified, factory-trained technicians. This is especially true for any work on electrical, hydraulic, or structural systems to ensure safety and compliance. Our Crane Operator Training programs clarify these responsibilities.

What specialized tools or equipment are needed for self-erecting tower crane repairs?

Repairs require specialized equipment beyond a standard toolbox. This includes model-specific diagnostic software, hydraulic pressure gauges, electrical multimeters, NDT (Non-Destructive Testing) equipment, and calibrated torque tools. Heavy components may also require mobile cranes or forklifts for safe handling.

How do electrical and hydraulic system checks contribute to the overall repair process?

These checks are crucial for accurate diagnosis. They help us pinpoint the root cause of a malfunction, such as faulty wiring or hydraulic contamination, rather than just treating symptoms. They are also vital for verifying that a repair is successful and the crane is operating safely.

What documentation is crucial for tracking repairs and ensuring compliance?

Essential documentation includes service logs, repair reports, and parts replacement records. This paperwork creates a complete maintenance history, which is vital for ensuring compliance with OSHA, aiding future diagnostics, and increasing the crane’s resale value.

How can repairs extend the lifespan and improve the performance of a self-erecting tower crane?

Properly executed repairs address wear and tear before it causes major failures. By replacing faulty components and restoring systems to optimal condition, repairs prevent stress on other parts, maintain lifting capacity and speed, and ensure safety systems function correctly. This proactive approach significantly extends the crane’s reliable service life.

What are the potential costs associated with self-erecting tower crane repairs?

Costs vary based on the issue but are influenced by several key factors:

- Labor: Rates for skilled, factory-trained technicians.

- Parts: The cost of OEM or high-quality aftermarket components.

- Specialized Equipment: Use of diagnostic tools, lifting equipment, or welding gear.

- Downtime: The hidden cost of lost productivity and project delays.

- Transportation: Costs to move the crane or large components to a repair facility.

Investing in preventative maintenance is the best way to control and avoid many of these costs.

Conclusion

When your project relies on a self-erecting tower crane, reliability and safety are non-negotiable. These machines require expert care to perform at their peak and avoid costly downtime.

Proactive maintenance is the best strategy. By staying ahead of issues with regular inspections and professional care, you ensure your crane remains a safe, compliant, and productive asset on your job site.

Our team of factory-trained technicians understands that when a crane is down, your project stops. We are committed to providing precise, efficient self erect tower crane repairs that get you back to work quickly without compromising on quality or safety.

Your self-erecting tower crane is a significant investment. Trust its care to professionals who understand these complex machines. We are here to help you minimize downtime and keep your projects moving forward.

For comprehensive and reliable crane solutions, explore our Crane Services. We provide expert support throughout Western and Central Pennsylvania, Ohio, West Virginia, and Maryland.