Why 3D Lift Planning is Essential for Modern Construction Projects

3D lift planning is a digital simulation technology that creates detailed, three-dimensional models of crane operations before they happen on the jobsite. This advanced planning method allows construction teams to visualize complex lifts, identify potential hazards, and optimize crane selection and positioning for maximum safety and efficiency.

Key aspects of 3D lift planning:

- Purpose: Simulate entire lifting operations in a virtual environment to prevent accidents and optimize performance

- Technology: Web-based software that integrates crane specifications, load data, and jobsite conditions

- Users: Project managers, crane operators, lift engineers, and rigging supervisors

- Benefits: Improved safety, reduced costs, improved efficiency, and better communication with stakeholders

- Industry adoption: Used by 94 of the top 100 crane companies in the United States

When it comes to project completion, one thing stands between success and failure: a thought out, effective lift plan. Without comprehensive planning, projects can experience costly downtime, safety incidents, and potential failure.

The technology has become the industry standard because it transforms complex lifting operations from guesswork into data-driven decisions. Modern 3D lift planning software includes databases of over 1,700 crane models and provides real-time calculations for ground bearing pressure, rigging requirements, and optimal crane configurations.

I’m Dave Brocious, and with over 30 years of experience in construction strategy and operations, I’ve seen how 3D lift planning transforms project outcomes by reducing risk and improving efficiency. At Sky Point Crane, we leverage this technology daily to ensure our clients’ projects are completed safely and on schedule.

Terms related to 3D lift planning:

What is 3D Lift Planning and Why is it the Industry Standard?

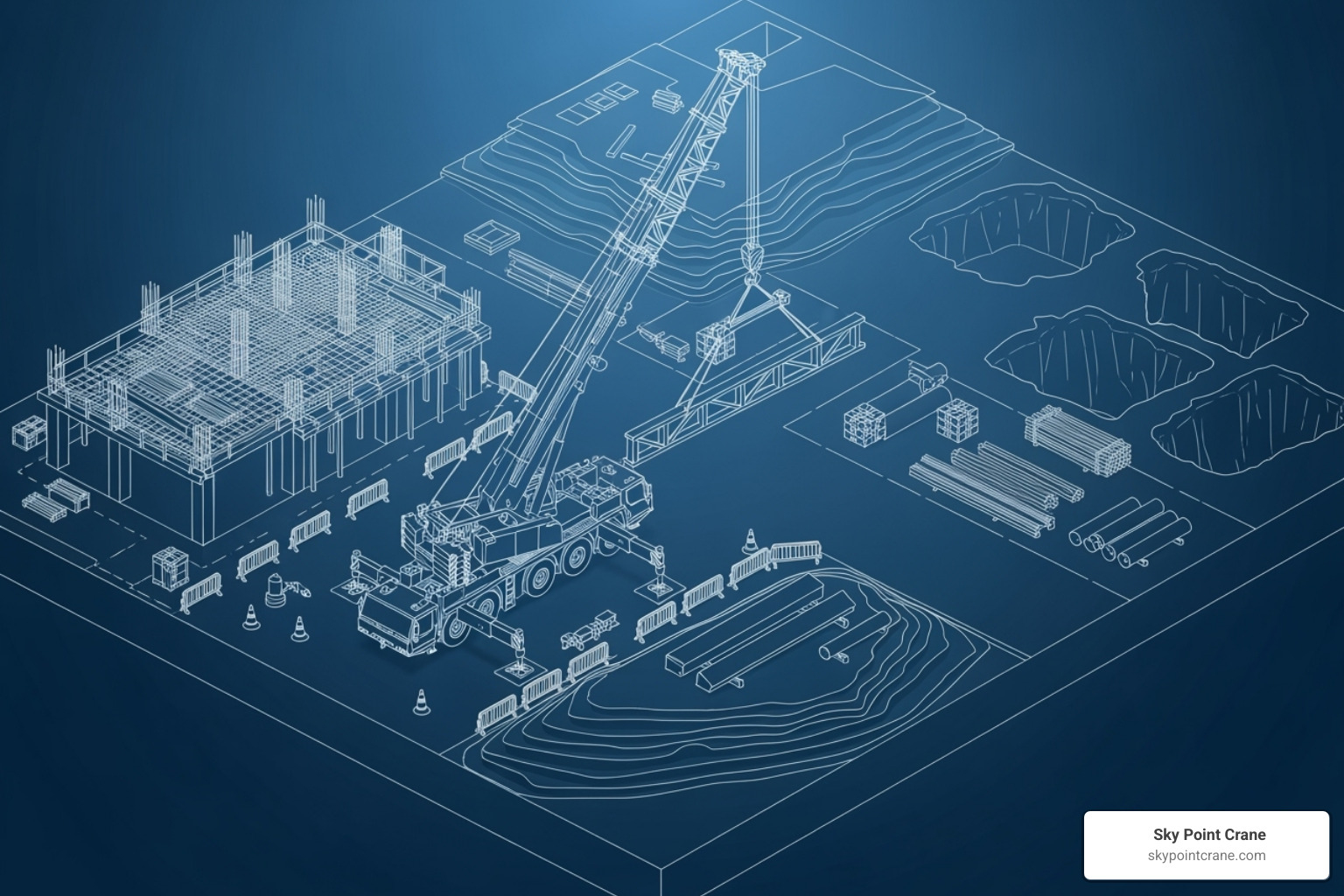

3D lift planning allows you to “rehearse” a complex crane lift on a computer, using a sophisticated virtual simulation to test every aspect of the operation before the crane arrives on site.

This technology is a comprehensive risk management tool for designing lifts, planning jobsites, and detailing rigging setups. As it’s web-based, our team can collaborate on lift plans from anywhere, whether on a project in Western Pennsylvania, Ohio, West Virginia, or Maryland. This means no software installations and instant access to the latest updates.

The numbers speak for themselves: 94 of the top 100 crane companies in the United States rely on this technology. When nearly every major player in the heavy construction industry adopts the same approach, it becomes the industry standard for good reason.

The Role of 3D Lift Planning in Successful Construction Projects

Defining the Purpose and Primary Users

As a rehearsal tool, 3D lift planning uses detailed virtual simulations during the pre-construction process to reveal potential problems before they become costly issues. A key feature is clash detection, which automatically identifies where the crane, load, or rigging might collide with obstacles like buildings or power lines.

This detail helps various team members:

- Lift engineers design the safest, most efficient lifting approach.

- Rigging supervisors prepare exact rigging configurations in advance.

- Crane operators gain confidence by understanding the required movements.

- Site superintendents get a clear visual roadmap for the operation.

- Project managers coordinate resources more effectively.

Crucially, client communication becomes crystal clear. We can show clients exactly what will happen, building confidence and ensuring alignment.

The Shift to a Digital Standard

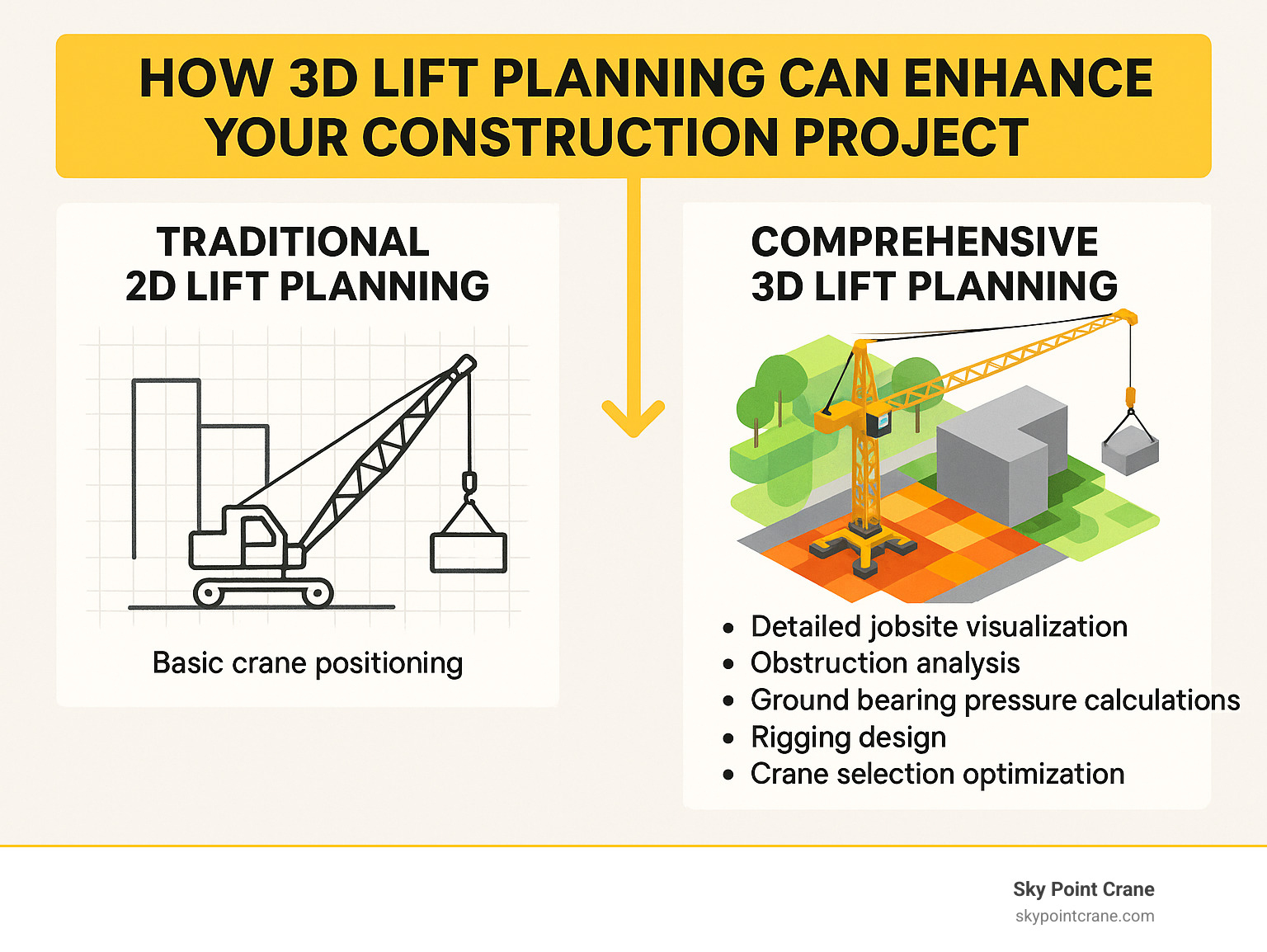

For years, lift planning relied on traditional methods like 2D sketches and guesswork, which had serious limitations in visualizing complex spatial relationships.

The shift to digital planning has revolutionized crane operations. Modern 3D lift planning delivers unparalleled accuracy by integrating real manufacturer crane data with detailed jobsite models and precise load information. As one industry professional noted, “The accuracy of 3D Lift Plan assures our clients that the cranes selected will perform the tasks required safely and efficiently.”

This accuracy enables data-driven decisions, allowing us to calculate exact ground bearing pressures and determine optimal crane positions. The widespread adoption across the industry proves it’s not a trend but a fundamental shift in industry best practices. When 94 of the top 100 companies use the same approach, it’s clear 3D lift planning has set a new standard for safe, efficient lifting.

3D Lift Planning: Setting the Standard for Safe and Efficient Lifts

The Transformative Benefits of Advanced 3D Lift Planning

3D lift planning is a game-changer for construction, changing uncertainty into confidence and guesswork into precision. It eliminates the gaps left by traditional methods by allowing us to see exactly what will happen before a lift begins. The results are clear: improved safety, increased efficiency, and significant cost savings. These benefits are the difference between a smooth project and one plagued by delays or safety incidents.

Enhancing Jobsite Safety and Mitigating Risk

Crane work is inherently dangerous, which is why safety is our top priority. 3D lift planning is a powerful tool for identifying and eliminating hazards before anyone is on site. By creating a detailed 3D model of the jobsite—including buildings, power lines, and other structures—potential collision points become obvious. We can virtually rotate the crane 360 degrees to spot any obstacles.

Ground bearing pressure is another critical safety factor addressed by the software. It calculates the exact pressure the crane will exert, telling us if crane mats are needed to distribute the load and avoid ground failures, which is essential for OSHA compliance. The technology also has built-in warnings for two-blocking and helps ensure operations stay within safe working loads. This detailed planning gives our NCCCO certified operators the confidence that comes from understanding every aspect of the lift in advance.

Boosting Efficiency and Reducing Project Costs

In crane operations, time is money. 3D lift planning prevents costly surprises and downtime by working out all the details in advance. The optimized crane selection feature alone can save thousands by finding the most economical configuration that meets all safety requirements. Instead of guessing or choosing an overly large crane, we can test different options virtually.

This precision extends to rigging design, allowing us to calculate sling angles and generate detailed equipment lists. This ensures the right gear is on site, eliminating delays. Furthermore, 3D lift planning creates streamlined communication. When everyone—from superintendents to operators—sees the same visual plan, misunderstandings and coordination delays are dramatically reduced, keeping projects on schedule and within budget.

How Contractors Can Benefit From a 3D Lift Plan

Improving Crane Selection and Utilization

3D lift planning has turned crane selection from an art into a precise science. Our software includes a comprehensive crane database with over 1,700 configurations, complete with detailed load chart analysis and operating parameters. We can “test drive” different cranes to find the best fit for the job’s specific requirements.

The software automatically handles complex radius calculations and boom clearance analysis. By inputting the load, pick, and set locations, the system identifies which cranes can perform the job safely and efficiently. This enables true fleet optimization, ensuring we select the perfect machine for each job—not one that is oversized and costly or undersized and unsafe. For our clients across Western Pennsylvania, Ohio, West Virginia, and Maryland, this means the right solution at the best price.

How to Add a Crane on 3D Lift Plans

The Core Components of an Effective 3D Lift Plan

An effective 3D lift plan requires fitting several crucial pieces together perfectly to create a comprehensive picture of the lifting operation. The process involves gathering the right data, leveraging powerful software, and delivering clear outputs for the team. When these elements work together, a 3D lift plan transforms complex operations into well-orchestrated successes.

Essential Inputs for an Accurate Plan

The accuracy of a 3D lift plan depends entirely on the quality of the initial information. Key inputs include:

- Load specifications: The exact weight and dimensions of the object being lifted, including all rigging, the load block, and accessories. We also determine the center of gravity.

- Jobsite layout and coordinates: The crane’s setup location, pick point, and set point, along with every building, road, and obstacle that could affect the operation.

- CAD drawings and aerial imagery: We can import CAD files, drone footage, or Google Earth images to create a precise digital replica of the site for maximum accuracy.

- Obstruction identification: We locate and model every potential interference, from power lines and scaffolding to underground utilities and temporary structures.

- Ground conditions: A critical safety factor. We assess if the ground is firm and graded to support the crane and its load, determining if crane mats are needed and calculating ground bearing pressure.

Key Software Features and Capabilities

Modern 3D lift planning software transforms raw data into powerful visual simulations. Key features include:

- 3D jobsite modeling: Creates a virtual replica of the work environment to test scenarios without real-world risk.

- Crane selection capabilities: Taps into databases of over 1,700 crane models to test configurations and find the most economical option.

- Rigging design tools: Uses comprehensive libraries of components to engineer the perfect rigging setup, automatically calculating sling angles and tension.

- Ground bearing pressure calculations: Automatically determines the pressure the crane will exert on the ground, helping specify necessary reinforcement.

- Lift simulation: Provides a dynamic preview of the entire operation, allowing us to identify issues that might not be obvious in static views.

- Safety features: Built-in warnings for two-blocking and angle limits help prevent accidents by keeping operations within safe parameters.

Outputs and Deliverables for Your Team

A completed 3D lift plan generates a suite of deliverables to ensure clear communication, execution guidance, and safety documentation.

- Detailed printouts: Comprehensive documents with the crane’s configuration, rigging specifications, load charts, and clearances, serving as the operation’s blueprint.

- Video simulations: Dynamic presentations showing the entire lift sequence, making complex operations easy for all stakeholders to understand.

- Rigging specifications: Precise lists detailing every required component, preventing delays from incorrect or missing gear.

- Crane configuration reports: Documents the exact setup requirements for the crane, including counterweight and outrigger spreads.

- Comprehensive lift narratives: Written explanations covering critical factors like wind restrictions, ground bearing pressures, and special support needs.

These deliverables create a complete communication package that keeps everyone informed, prepared, and safe, while also providing documentation for regulatory compliance.

Frequently Asked Questions about 3D Lift Planning

Over my 30 years in construction, I’ve fielded countless questions about 3D lift planning. Whether you’re a project manager trying to understand the process or a contractor considering this technology for the first time, these are the questions that come up most often in our conversations with clients across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland.

What specific information is needed to start a 3D lift plan?

Getting started with a 3D lift plan is like gathering ingredients for a recipe – you need the right information to create something that actually works. The good news is that most of the data you need is probably already in your project files.

The weight and dimensions of what you’re lifting form the foundation of any good plan. This isn’t just the object itself, but everything that’ll be hanging from the hook – rigging, slings, spreader bars, and any other hardware. We’ve seen too many lifts go sideways because someone forgot to account for a heavy lifting beam or underestimated the rigging weight.

Your jobsite layout and obstructions are equally critical. We need to know about buildings, power lines, existing structures, parked equipment, material piles – basically anything that could get in the way of our crane or load. Even something as simple as a temporary fence or a tree can impact the lift plan significantly.

Pick and set locations tell us where the load starts and where it needs to end up. The more precise these coordinates, the better we can optimize the crane position and movements.

Here’s where modern technology really shines: we can import site plans, CAD files, or even Google Earth images to create an incredibly accurate digital representation of your jobsite. Drone imagery is particularly helpful for getting current site conditions. The more detailed information you can provide upfront, the more accurate and useful your 3D lift plan will be.

How user-friendly is modern 3D lift planning software?

I remember when crane planning software required an engineering degree just to open the program. Those days are long gone. Modern 3D lift planning solutions are designed with real-world users in mind – people who need to get things done quickly and accurately without wrestling with complicated interfaces.

Most current software uses a step-by-step approach that walks you through the planning process. You don’t need to be a computer expert or have years of training to create effective lift plans. The interfaces are intuitive, with visual cues and prompts that guide you through each stage of the planning process.

Web-based access is another game-changer. You can pull up your lift plans from anywhere with internet access – whether you’re in the office, on site, or reviewing plans with a client. No more worrying about software installations, updates, or compatibility issues between different computers.

At Sky Point Crane, we make sure our team stays current with these tools, and we’re always impressed by how quickly new users can become proficient. Most software providers offer extensive training resources – online classes, tutorials, video guides, and support teams that actually know what they’re talking about. As one of our industry colleagues put it perfectly: the software is designed for “simplicity and ease of use” without sacrificing the powerful capabilities you need for complex lifts.

Can a 3D lift plan be used for any type of crane?

This is one of my favorite aspects of modern 3D lift planning – the answer is absolutely yes. Whether you’re working with a compact telescopic crane for a small job or a massive crawler crane for heavy industrial work, the software can handle it.

Comprehensive crane databases are the secret sauce here. Our planning tools include data and graphics for over 900 different crane models, with an OEM lift chart database that keeps growing – we’re talking about more than 1,700 crane configurations and counting. This means the software doesn’t just give you generic calculations; it uses the exact specifications, load charts, and operational parameters for your specific crane model.

Manufacturer collaboration makes this possible. Crane manufacturers work directly with software developers to ensure their equipment data is accurately represented in the planning tools. Many even make their crane models available at no additional cost within the software, which benefits everyone in the industry.

This comprehensive approach means that whether we’re deploying a hydraulic truck crane for a routine lift or bringing in specialized equipment for a complex industrial project, the 3D lift plan reflects the real-world capabilities and limitations of that exact crane. It’s not guesswork or approximations – it’s based on the manufacturer’s own specifications and load charts.

The result is a planning process that works for any crane in our fleet, ensuring that every lift plan is custom to the specific equipment that’ll be on your jobsite.

Maximize Your Project’s Success with Expert Planning

When you’re managing a heavy construction project, every decision matters. The difference between a smooth operation and a costly nightmare often comes down to one thing: thorough, expert planning. 3D lift planning transforms how we approach crane operations, turning what used to be educated guesswork into precise, data-driven decisions.

Think about it this way – would you rather find a problem when your crane is already on site with a full crew waiting, or identify and solve it weeks ahead of time from the comfort of your office? That’s the power of detailed simulations and data-driven insights. We can spot potential issues before they become expensive headaches, improve safety protocols before anyone steps foot on the jobsite, and ensure your project stays on schedule and within budget.

This level of meticulous planning does more than just prevent problems. It optimizes resource allocation by helping us select exactly the right crane for your specific lift, fosters clear communication across all stakeholders with visual simulations everyone can understand, and minimizes surprises that can derail even the best-planned projects. When everyone knows what to expect, projects run smoother.

At Sky Point Crane, we’ve made 3D lift planning a cornerstone of our comprehensive lifting solutions across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. Our team combines decades of hands-on experience with cutting-edge planning technology, backed by our NCCCO certified operators who understand both the digital plan and the real-world execution.

We’ve seen how this technology transforms project outcomes. It’s not just about having fancy software – it’s about using that technology to deliver the precision, safety, and efficiency your projects demand. Whether you’re lifting a single beam or coordinating a complex multi-crane operation, we bring the same level of detailed planning and professional execution to every job.

Ready to experience the difference that expert planning makes? For expert assistance with your next project, explore our 3D Lift Planning services. Let us help you lift your project to new heights, safely and efficiently.