What Is a Rough Terrain Crane and Why Does It Matter?

Rough terrain crane specialists understand that construction projects don’t always happen on perfectly level ground. These powerful machines are designed specifically for challenging, uneven jobsites where other cranes simply can’t operate effectively.

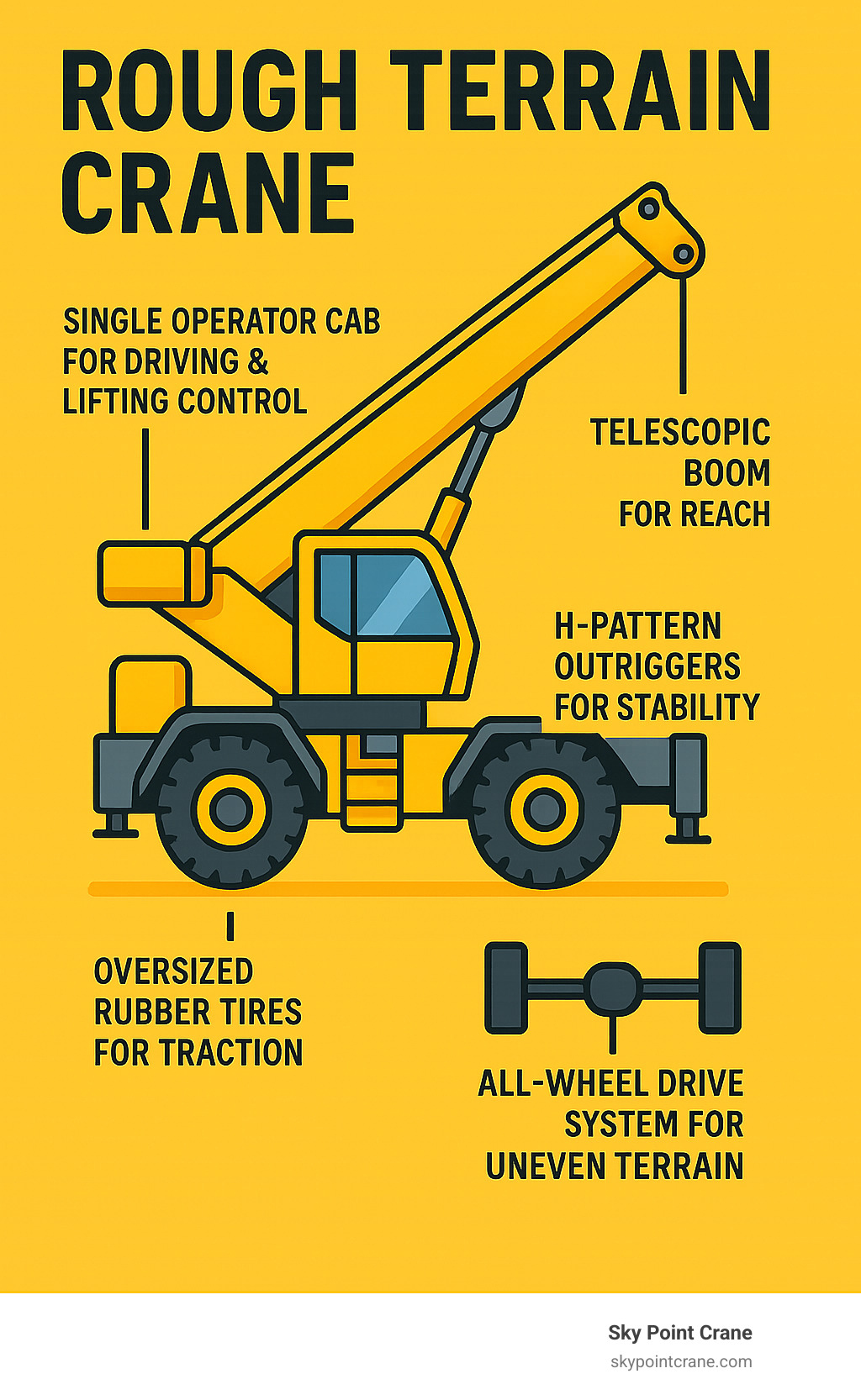

Key Characteristics of Rough Terrain Cranes:

- Single cab design – One operator controls both driving and lifting from the same position

- All-wheel drive and steering – Steer tight spaces and difficult terrain with precision

- Outrigger stabilization – H-pattern outriggers provide stability on uneven ground

- Pick-and-carry capability – Can move loads while lifted (within safe parameters)

- Compact footprint – Maneuver in confined spaces where larger cranes won’t fit

- Not road-legal – Must be transported by trailer between jobsites

These cranes fill the gap between smaller mobile cranes and massive crawler cranes. With lift capacities ranging from 30 to 165 tons and boom lengths from 30 to 205 feet, they deliver serious lifting power while maintaining the mobility needed for challenging construction environments.

Unlike all-terrain cranes built for highway travel, rough terrain cranes focus entirely on off-road performance and jobsite maneuverability. Their oversized tires, robust suspension, and lower center of gravity make them the go-to choice when you need reliable lifting power on unprepared ground.

I’m Dave Brocious, and with over 30 years of experience in crane services and construction equipment, I’ve seen how rough terrain crane selection can make or break a project timeline. At Sky Point Crane, we’ve helped countless construction managers steer the complexities of equipment selection for challenging Western Pennsylvania jobsites.

Simple Rough terrain crane word guide:

Core Design Features for Best Mobility

What makes a rough terrain crane truly special isn’t just its lifting power – it’s how these machines are engineered from the ground up to go where other cranes simply can’t. Every design choice focuses on one goal: getting the job done on challenging terrain without compromising safety or efficiency.

The first thing you’ll notice about any rough terrain crane is its massive tires. These aren’t ordinary truck tires – they’re specially designed for maximum grip and flotation over soft ground. Whether you’re dealing with muddy construction sites after a rainstorm or rocky terrain that would stop most vehicles, these oversized tires keep the crane moving forward.

But tires are just the beginning. All-wheel drive gives these cranes the traction they need to climb slopes and power through challenging conditions. Add all-wheel steering to the mix, and you’ve got a machine that can maneuver in spaces that seem impossibly tight. I’ve watched operators thread these cranes through construction sites with obstacles everywhere, making turns that would be impossible with conventional steering.

One of the most impressive capabilities is pick-and-carry functionality. This means the crane can lift a load and actually drive with it – safely, within specific limits outlined in the load charts. Imagine the time savings when you can pick up a steel beam and carry it exactly where it needs to go, rather than setting it down and repositioning the entire crane.

The lower center of gravity design gives these cranes their remarkable stability. This isn’t an accident – every component placement is carefully engineered to keep the machine balanced, even when working on slopes or uneven ground that would challenge other equipment.

The Role of Outriggers and All-Wheel Drive

When a rough terrain crane arrives at your jobsite, the real magic happens when those outriggers extend. These aren’t just simple supports – they’re sophisticated stabilization systems that transform the crane from a mobile vehicle into a rock-solid lifting platform.

The H-pattern outriggers can extend independently, which is crucial when you’re working on uneven terrain. Each outrigger can be adjusted to different lengths and heights, allowing the operator to level the crane perfectly even on challenging ground. This flexibility is what allows these cranes to work safely on slopes and irregular surfaces where other equipment would struggle.

Modern rough terrain cranes even feature asymmetrical outrigger systems that adapt to space constraints. If you’re working near a building or fence on one side, the outriggers can extend different distances while still maintaining stability. This innovation has opened up possibilities for working in confined spaces that were previously impossible.

The all-wheel drive system works hand-in-hand with the outriggers to provide improved traction during positioning. Whether you’re navigating through mud, loose gravel, or construction debris, all four wheels pulling together keep the crane moving confidently. This is especially important when navigating confined spaces where there’s no room for error or getting stuck.

At Sky Point Crane, our operators understand that proper outrigger setup is fundamental to safe operations. It’s a cornerstone of our commitment to Crane and Rigging Safety, and we ensure every operator is thoroughly trained in these critical procedures.

How the Single-Cab Design Improves Operation

The single-cab design of a rough terrain crane might seem simple, but it’s actually a stroke of engineering genius. Instead of having separate areas for driving and crane operation, everything happens from one comfortable, well-positioned operator station.

This dual-purpose operation means one skilled operator can drive the crane into position, extend the outriggers, and immediately begin lifting operations – all without leaving their seat. There’s no time lost switching between different control stations or adjusting to different viewing angles.

The efficiency gains are remarkable. Reduced setup time means your project moves faster, and the seamless transition from driving and lifting from one cab eliminates the coordination challenges that can slow down operations. When time is money on a construction project, these advantages add up quickly.

Increased maneuverability comes from having all controls in one place with one operator who understands exactly how the machine will respond. There’s no miscommunication between a driver and a crane operator because they’re the same person.

Perhaps most importantly, the liftd single cab provides improved operator visibility. The operator can see the load, the landing zone, and any potential obstacles from one optimal vantage point. This improved visibility is crucial for both safety and precision, especially when working in tight quarters or around other equipment and workers.

This thoughtful design approach is why rough terrain cranes have become the go-to choice for so many challenging construction projects. They’re not just powerful – they’re smart, efficient, and designed with real-world jobsite conditions in mind.

Rough Terrain Crane vs. Crawler Crane: Key Differences

When you’re planning a heavy lift, you’ll often find yourself choosing between a rough terrain crane and a crawler crane. Both are powerhouse machines, but they’re built for completely different situations. Think of it like choosing between a pickup truck and a semi-trailer – both can haul heavy loads, but one’s built for versatility while the other’s designed for maximum capacity.

| Feature | Rough Terrain Crane | Crawler Crane |

|---|---|---|

| Mobility | High on rough, uneven terrain; pick-and-carry | Low on job site; requires disassembly for transport |

| Ground Preparation | Minimal; handles challenging surfaces | Requires more stable, level ground; ground pressure distribution |

| Setup Time | Relatively quick | Significant; requires assembly/disassembly |

| Lifting Capacity | Moderate to high (30-165 tons) | Very high to extreme (hundreds to thousands of tons) |

| Ideal Job Site | Remote, uneven, confined, frequently changing | Large, long-term, stable ground, heavy lifts |

Mobility and Transport

The biggest difference you’ll notice is how these cranes get around. A rough terrain crane rolls on large rubber tires with all-wheel drive, making it incredibly nimble on challenging terrain. It can steer muddy construction sites, rocky ground, or sandy areas that would stop other equipment in their tracks. Need to reposition for the next lift? No problem – it can pick up and move across the jobsite in minutes.

Here’s the catch though: these cranes are not road-legal for highway travel. They need to hitch a ride on a trailer to get from one project to another. But once they arrive, they’re ready to work immediately. We keep a full range of Equipment to handle these transport needs efficiently.

Crawler cranes take a completely different approach. They move on tracks like a bulldozer, which gives them incredible stability and lets them distribute their weight over soft ground without sinking. But they’re slow – think tortoise, not hare. Moving them between jobsites means disassembling them, loading multiple truckloads of parts, then putting everything back together at the new location. It’s a major undertaking that can take days.

Stability and Lifting Power

Both cranes are incredibly stable, but they achieve it in different ways. A rough terrain crane uses outrigger-based stability – those powerful legs extend out to create a rock-solid platform for lifting. Once properly set up, these outriggers can level the crane on surprisingly uneven ground and provide the stability needed for impressive lifts.

The real advantage here is performance on soft ground. Those independent outriggers can adapt to slopes and uneven surfaces that would challenge other crane types. For projects where you need to move around frequently or work in tight spaces, this flexibility is invaluable.

Crawler cranes rely on their wide base stability from those tracks. They don’t always need outriggers because their footprint is already massive. This design makes them the champions of heavy-lifting capabilities – we’re talking hundreds or even thousands of tons. They’re built for those massive, long-term projects where maximum capacity trumps mobility.

The trade-off is clear: if you need ultimate lifting power and plan to stay in one spot for weeks or months, crawler cranes are hard to beat. But for suitability for long-term projects that require flexibility, frequent repositioning, or working in confined areas, the rough terrain crane is often the smarter choice.

Capabilities and Applications of the Rough Terrain Crane

When you need serious lifting power in places where other cranes fear to tread, the rough terrain crane steps up to the plate. These machines are the Swiss Army knives of the crane world – versatile, reliable, and surprisingly powerful for their compact size.

What makes these cranes so valuable is their ability to deliver powerful performance in a compact package. They can reach impressive heights and handle substantial weights without requiring the massive footprint of larger cranes. This efficiency translates directly into cost savings and faster project timelines – something every project manager appreciates.

Whether you’re dealing with a cramped industrial facility or a remote construction site miles from the nearest paved road, a rough terrain crane consistently delivers results. The combination of versatility and efficiency makes these machines indispensable for our comprehensive Crane Services, especially when adaptability is key to project success.

Typical Specifications of a Rough Terrain Crane

Understanding what a rough terrain crane can actually do helps you determine if it’s the right fit for your project. These specifications aren’t just numbers on paper – they represent real-world capabilities that can make or break a job.

Lift capacities for rough terrain cranes typically range from 30 to 165 US tons. That’s enough muscle to handle everything from HVAC units to structural steel beams. Main boom lengths stretch from 30 to 205 feet, giving you the reach needed for most construction and industrial applications.

When you need to go even higher, these cranes can achieve maximum tip heights up to 299 feet. Add a jib for extended reach, and you’re looking at jib lengths from 10 to 109 feet. These numbers mean you can tackle jobs that would otherwise require much larger, less maneuverable equipment.

For a real-world example, check out this Example Spec Sheet for a high-capacity rough terrain crane. It shows exactly how these impressive capabilities translate into practical lifting solutions for challenging job sites.

Industries and Applications

The beauty of a rough terrain crane lies in its ability to work almost anywhere. These machines don’t discriminate – they’ll tackle jobs in muddy construction sites, cramped industrial facilities, and remote locations that would challenge any other piece of equipment.

Construction sites are natural homes for these cranes, especially when you’re dealing with uneven ground, mud, or tight access. They excel at everything from setting foundation elements to erecting structural steel where the ground isn’t cooperating.

Industrial maintenance projects love rough terrain cranes because they can squeeze into existing facilities and handle the rough terrain that often surrounds industrial plants. Petrochemical plants, refineries, and manufacturing facilities all benefit from their compact footprint and precise control.

Infrastructure development projects in remote areas rely heavily on these machines. Whether you’re building bridges in rough terrain, installing power and communication lines across challenging landscapes, or working on pipeline projects miles from civilization, a rough terrain crane gets the job done.

We’ve deployed these versatile machines across all the Markets We Serve throughout Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. From urban renewal projects to remote industrial installations, rough terrain cranes prove their worth by going where others can’t and lifting what needs to be moved.

Technological Advancements and Safety

The crane industry has come a long way from the basic machines of decades past. Today’s rough terrain cranes are sophisticated pieces of equipment that would make my younger self amazed at what’s possible. These technological leaps aren’t just impressive – they’re making our job sites safer and more efficient every day.

Step into a modern rough terrain crane cab today, and you’ll see digital displays that look more like a spaceship than construction equipment. Advanced operator assistance systems now monitor everything happening during a lift, from load weight to boom angle to outrigger pressure. It’s like having a co-pilot who never gets tired or distracted.

Load monitoring technology has become a game-changer for safety. These systems constantly calculate whether a lift is within safe parameters and alert operators before problems occur. No more guessing or relying solely on experience – though experience still matters plenty.

Telematics for fleet management lets us keep tabs on our equipment even when we’re back at the office. We can see where each crane is, how it’s performing, and when it needs maintenance. This remote monitoring means fewer surprises and more uptime for our clients.

One feature that makes both operators and accountants happy is ECO mode. This fuel-saving technology reduces consumption without sacrificing performance. It’s a win-win that helps keep costs down and reduces our environmental footprint.

Innovations in Design and Operation

The mechanical improvements in modern rough terrain cranes are just as impressive as the digital advances. Engineers keep finding ways to make these machines more versatile and capable.

Improved outrigger designs have revolutionized how we set up on challenging sites. The latest asymmetrical outrigger systems let each leg extend to different lengths independently. This means we can set up stable operations even when space is tight on one side – something that would have been impossible with older, rigid systems.

Multiple steering modes give operators incredible control over positioning. Two-wheel steering works great for highway transport, while four-wheel steering provides tight turning radius on job sites. The real magic happens with crab steering, which lets the crane move diagonally. I’ve seen operators use this to slide perfectly into position between obstacles that seemed impossible to steer.

Improved hydraulic systems deliver the kind of smooth, precise control that makes delicate lifts look effortless. Modern systems respond instantly to operator input while filtering out jerky movements that could destabilize a load. Combined with our 3D Lift Planning services, these refined controls help us execute even the most complex lifts with confidence.

Focus on Safety and Efficiency

All these technological advances point toward one critical goal: keeping everyone safe while getting the job done right. Integrated stability control systems act as a safety net, continuously monitoring the crane’s stability and intervening if limits are approached. These systems can prevent accidents that might happen in split-second situations where human reaction time isn’t fast enough.

Technology is only as good as the people operating it, though. That’s why all our operators are NCCCO certified – they’ve proven they understand both the equipment and the safety protocols that keep everyone protected. This combination of advanced technology and skilled operators creates multiple layers of protection on every job.

Comprehensive lift planning remains the foundation of safe crane operations. We analyze every aspect of a lift before the crane even arrives on site, considering everything from ground conditions to weather patterns. When you combine thorough planning with modern crane technology, the result is operations that are both safer and more efficient.

These improvements also contribute to reduced environmental impact through more efficient fuel use and optimized operations. Modern rough terrain cranes accomplish more work with less fuel, creating a smaller carbon footprint while maintaining the power and reliability our clients depend on.

Conclusion: Selecting the Right Crane for Your Project

After exploring rough terrain cranes, one thing becomes crystal clear: these machines are the ultimate problem-solvers for challenging job sites. When you’re facing muddy ground, tight spaces, or remote locations where other cranes fear to tread, a rough terrain crane steps up to the plate.

The beauty of these cranes lies in their versatility for challenging sites. Their oversized tires grip what others can’t, their outriggers level what seems impossible, and their single-cab design keeps operations flowing smoothly. Whether you’re erecting steel on a hillside construction site or maintaining equipment in a cramped industrial facility, these machines deliver the perfect blend of power and agility.

But here’s the thing – selecting the right crane isn’t just about picking the biggest or most impressive machine. It requires a professional assessment that considers your specific lifting requirements, site conditions, ground stability, and access limitations. Factors like lift capacity, boom reach, ground pressure, and setup time all play crucial roles in determining whether a rough terrain crane is your best choice.

That’s where Sky Point Crane expertise makes all the difference. With over 30 years of experience serving Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, we’ve seen every type of challenging site imaginable. Our NCCCO certified operators understand how to maximize the capabilities of our rough terrain crane fleet while maintaining the highest safety standards.

We don’t just drop off equipment and walk away. Our comprehensive approach includes detailed lift planning, site assessment, and ongoing project support. When you combine our modern crane fleet with advanced tools like 3D Lift Planning, you get lifting solutions that are both safe and efficient.

Every project is unique, and that’s exactly why we offer personalized consultation to match you with the perfect crane for your specific needs. Whether it’s a quick pick-and-carry operation or a complex multi-day project, we have the expertise and equipment to get it done right.

Ready to tackle your next challenging project with confidence? Request a Quote for your next project, and let’s discuss how our rough terrain crane services can keep your job site moving forward, no matter how rough the terrain gets.