Understanding Industrial Warehouse Pallet Racking

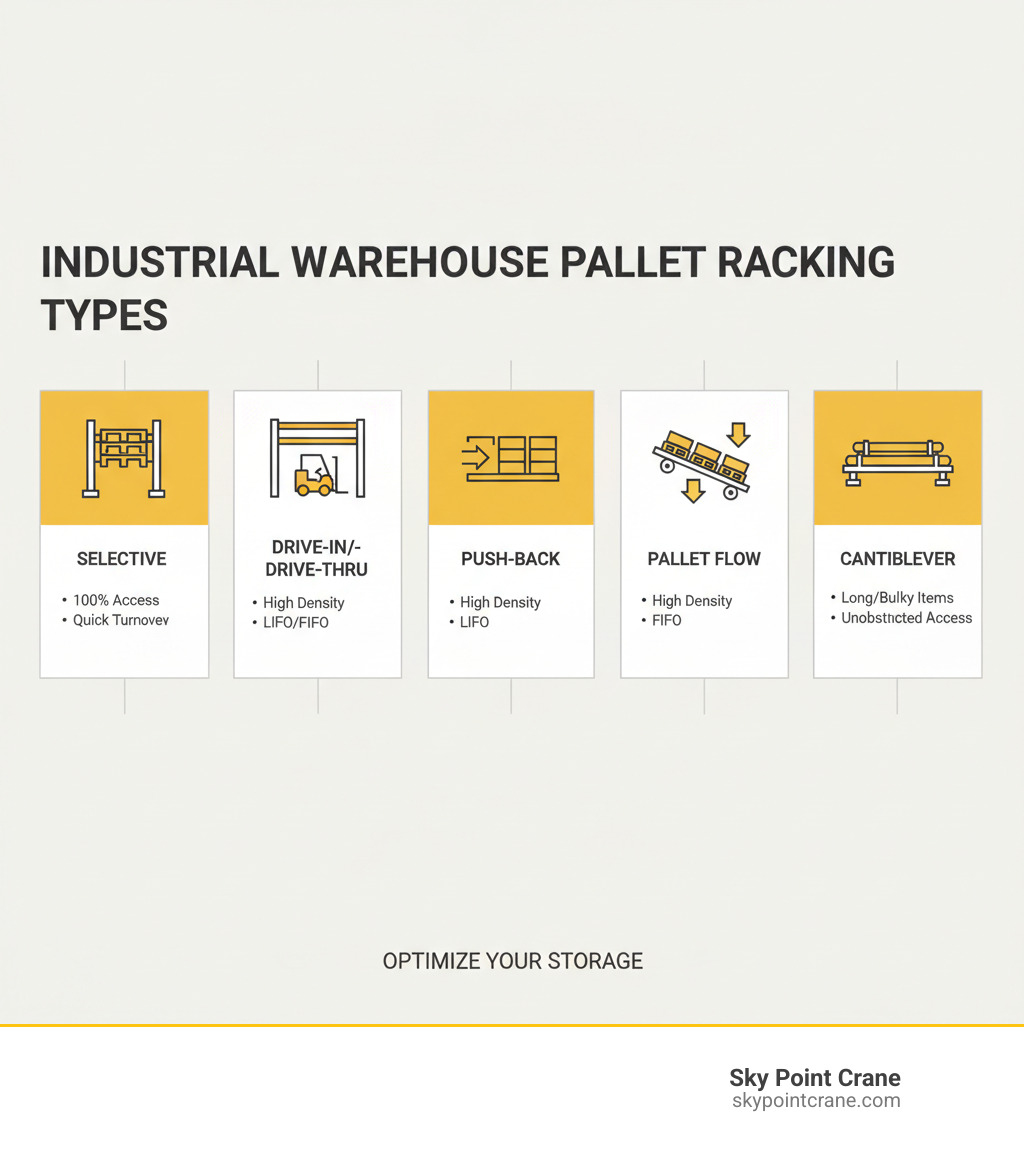

What is industrial warehouse pallet racking? It’s a critical storage system designed to organize and store materials on pallets in modern warehouses and distribution centers. These systems allow for efficient vertical storage, maximizing space and streamlining operations. Key types include:

- Selective: Offers 100% product accessibility. Ideal for high turnover inventory.

- Drive-In/Drive-Thru: High-density storage. Drive-in uses Last-In, First-Out (LIFO), while Drive-Thru allows First-In, First-Out (FIFO).

- Push-Back: High-density LIFO system. Pallets slide on carts up to six deep.

- Pallet Flow: High-density FIFO system using gravity-fed rollers. Great for date-sensitive goods.

- Cantilever: Best for long, bulky items like lumber or pipe, providing unobstructed access.

In today’s supply chain, optimizing storage is essential. Industrial warehouse pallet racking is the backbone of efficient material handling, changing unused vertical space into valuable storage for better inventory control and faster access. This guide will explore the types, components, and benefits of pallet racking to help you choose the right system, boost productivity, and lower operational costs.

I am Dave Brocious, an executive with over 30 years of experience in manufacturing and distribution. My expertise in optimizing business operations is particularly valuable when implementing complex industrial warehouse pallet racking systems for our clients. In this guide, we’ll explore how to make your warehouse more efficient.

Key terms for industrial warehouse pallet racking:

The Anatomy of a Pallet Rack: Construction and Key Components

An industrial warehouse pallet racking system is a robust framework engineered to maximize vertical storage. Built for durability and significant load capacities, these structures offer extensive customization to fit unique storage needs. Each component, from the uprights to the beams, is vital for the system’s strength and functionality. Understanding these parts is the first step toward optimizing your industrial storage.

Key Components of an Industrial Warehouse Pallet Racking System

Let’s look at the essential elements of these powerful storage systems.

Upright Frames: These are the vertical supports of the system, made of two columns connected by horizontal and diagonal braces. They come in various heights and depths to hold different weights. A common 42-inch frame depth is ideal for a standard 48-inch deep pallet, allowing a stable 3-inch overhang.

Load Beams: These horizontal pieces connect two uprights, creating the shelves for pallets. Beams come in different lengths, with 8-foot beams being popular for holding two standard pallets. Their height (face size) determines load capacity, and they can be adjusted in 2-inch increments for flexibility.

Wire Decking: While optional, these wire mesh decks are highly recommended for safety. Placed on load beams, they create a solid surface, improve fire safety by allowing sprinkler access, and prevent items from falling. They can typically support up to 2500 pounds of uniformly distributed weight.

Pallet Supports: These channel-shaped pieces run front-to-back across load beams, providing extra support for pallets, especially if they don’t perfectly fit the beam spacing.

Footplates (Baseplates): These flat plates are anchored to the concrete floor with anchor bolts, which is crucial for the stability and safety of the entire rack system, especially in seismic zones.

Braces: These diagonal and horizontal members connect the two columns of an upright frame, providing structural integrity and rigidity.

Common Accessories and Their Purpose

A range of accessories can improve the safety, durability, and functionality of your industrial warehouse pallet racking system.

Column Guards (Post Protectors) are shields installed at the base of uprights to protect them from forklift impacts, reducing the risk of structural damage.

Row Spacers connect back-to-back rack rows to ensure consistent flue space (for fire safety) and add stability. Wall Ties anchor single rows to an adjacent wall for extra support.

Safety Netting or Mesh Panels are installed on the back or sides of racking to prevent items from falling and injuring personnel. Steel mesh panels are a common alternative.

Flue Guards are specialized accessories that ensure proper vertical flue space within beam levels, which is critical for fire safety and sprinkler effectiveness.

Here are some essential safety accessories for your industrial warehouse pallet racking:

- Column Guards (for impact protection)

- Row Spacers (for stability and flue space)

- Wall Ties (for securing single rows to walls)

- Safety Netting/Mesh Panels (to prevent falling items)

- Drop Pins (to prevent beams from accidentally disengaging)

- Load Labels (to clearly indicate maximum load capacity)

Materials and Construction: Regular vs. Heavy-Duty

The materials used for your industrial warehouse pallet racking determine its durability and capacity.

Roll-Formed Steel is the most common type, often identified by teardrop-shaped holes on the uprights. It’s easy to assemble and adjust, making it ideal for warehouses with changing inventory. Regular duty units typically have an upright capacity of around 16,000 lbs.

For tougher jobs, Structural Steel is built from hot-rolled steel channels, making this bolt-together system stronger and more rigid. It’s designed for greater weight capacity and is highly resistant to forklift abuse. Heavy-duty units can have upright capacities of 28,300 lbs or more, making them suitable for high-impact environments or rack-supported buildings.

Both types commonly feature a durable powder coating or baked enamel finish for corrosion protection. When choosing, consider load weights, forklift traffic, and adherence to General requirements for storage – OSHA for safety and compliance.

A Guide to Common Pallet Racking System Types

Choosing the right industrial warehouse pallet racking system is a strategic decision balancing storage density, accessibility, inventory rotation methods (LIFO vs. FIFO), and cost. Each system optimizes different aspects of warehouse operations, from picking efficiency to space utilization. We aim to maximize your commercial storage solutions to meet your unique business needs.

Selective Racking

Selective pallet racking is the most common and flexible pallet storage system in the material handling industry.

- 100% Accessibility: Every pallet position is directly accessible, making it ideal for operations requiring immediate access to all products.

- Quick Turnover: This system is perfect for inventory that is rapidly depleted and restocked.

- Teardrop Style: The “teardrop” design is a popular roll-formed style, allowing for easy beam adjustment without special tools.

- Cost-Effective: Selective systems are less expensive per pallet position than higher-density counterparts, especially for initial setup.

- Configurations: Available in single-deep or double-deep (requiring a specialized reach truck), offering some flexibility in density.

Drive-In & Drive-Thru Racking

These systems offer high-density storage by allowing forklifts to drive directly into the rack structure.

- High-Density Storage: By reducing aisles, these racks significantly increase storage density, making them excellent for large quantities of similar products.

- LIFO (Last-In, First-Out) for Drive-In: With a common entry/exit, the last pallet loaded is the first retrieved. This is ideal for products where turnover is not critical.

- FIFO (First-In, First-Out) for Drive-Thru: With entry points at both ends, forklifts can load from one side and unload from the other, ensuring the oldest inventory is retrieved first. This is crucial for perishable goods.

- Fewer Aisles: The trade-off for high density is reduced selectivity, as forklifts must steer within the lanes.

- Bulk Storage: Best suited for bulk storage of homogeneous products with large quantities of the same SKU.

Push-Back Racking

Push-back racking combines high-density storage with improved selectivity compared to drive-in systems.

- High-Density, LIFO System: This system stores pallets up to six deep on a slight incline, operating on a LIFO principle.

- Wheeled Carts: Pallets are placed on nested carts that roll along rails. When a new pallet is loaded, it “pushes back” the previous ones.

- Gravity-Fed: When a pallet is removed, the remaining pallets automatically glide forward to the picking face.

- Good Selectivity: Each lane can store a different product, offering better selectivity than drive-in racks.

Pallet Flow Racking

Pallet flow racking (or gravity flow rack) is a dynamic storage system designed for high-density, FIFO inventory management.

- FIFO System: Pallets are loaded from one end and flow by gravity down an inclined conveyor to the picking face at the other end, ensuring First-In, First-Out rotation.

- Gravity Rollers: The system uses gravity to move pallets, saving space, labor, and energy.

- Separate Loading/Picking Aisles: Loading and unloading occur in separate aisles, preventing bottlenecks and improving efficiency.

- Ideal for Date-Sensitive Goods: Widely used for perishable items, high-volume consumer goods, or any product requiring strict FIFO management.

Pallet racking systems are essential for modern warehouses, and understanding these fundamental types is key to optimizing your operations.

Choosing the Right Industrial Warehouse Pallet Racking System

Selecting the ideal industrial warehouse pallet racking system is a critical decision that impacts operational smoothness, team safety, and your bottom line. It’s about engineering a smart storage solution custom to your unique needs.

Factors to Consider Before You Buy

When helping clients in Pennsylvania, Ohio, West Virginia, and Maryland, we carefully look at several key factors.

Warehouse Layout & Dimensions

- Ceiling Height: Determines the maximum rack height. A minimum 18-inch clearance from sprinklers to the top of the load is required.

- Floor Space: Dictates the choice between high-density systems (e.g., drive-in) and high-accessibility systems (e.g., selective).

- Aisle Width: Must accommodate forklifts for safe and efficient movement. Narrower aisles increase storage but may require specialized forklifts.

Product Type & Pallet Dimensions

- Pallet Dimensions: Guide the selection of rack depth and beam length. A 42-inch deep frame is common for a 48-inch deep pallet, providing a 3-inch overhang for stability.

- Load Weight: Determines the required capacity for uprights and beams. Never exceed the rated capacity.

- Product Characteristics: Fragile, perishable, or oddly shaped items may need special decking or systems like cantilever racks for long, bulky goods.

Throughput & Inventory Management

- Inventory Rotation (LIFO/FIFO): Your product’s shelf life determines the system. Drive-in/push-back are LIFO; drive-thru/pallet flow are FIFO.

- Accessibility: Decide if you need immediate access to every item (selective) or if maximizing bulk storage is the priority (drive-in).

- Order Picking Strategy: Full pallet, case, or item picking will influence system design.

Budget & Return on Investment (ROI)

- Initial Cost vs. Long-Term Savings: High-density systems may cost more initially but save space and operational costs long-term. Selective racking is often the most budget-friendly start.

- Forklift Type: Your current or planned forklifts must be compatible with the chosen racking system.

Here’s a handy table to quickly compare some of the common systems:

| Rack Type | Density | Accessibility | Cost (per pallet) | Inventory System |

|---|---|---|---|---|

| Selective | Low | High | Low | FIFO/LIFO |

| Drive-In | Very High | Low | Medium | LIFO |

| Drive-Thru | Very High | Low | Medium | FIFO |

| Push-Back | High | Medium | High | LIFO |

| Pallet Flow | High | Medium | High | FIFO |

Safety Best Practices for Industrial Warehouse Pallet Racking

Safety is non-negotiable when dealing with industrial warehouse pallet racking. Following strict safety protocols is essential.

- Regular Inspections: Conduct routine audits with a qualified inspector following Rack Manufacturers Institute (RMI) standards.

- Never Overload Your Racking System: Use clearly visible Load Labels showing maximum weight capacity and never exceed them.

- Damaged Components: Report and repair any damage immediately with qualified professionals.

- Proper Anchoring: Securely anchor all uprights to the concrete floor using footplates and anchor bolts.

- Operator Training: Ensure all forklift operators are properly trained and certified.

- Aisle Clearance: Keep aisles clear of obstructions for safe forklift operation.

- Column Guards (Post Protectors): Install these at the base of uprights to minimize damage from forklift impacts.

- Drop Pins: Use two per beam to prevent accidental disengagement.

Installation and Maintenance Requirements

Proper installation and ongoing maintenance are key to the long life and safety of your industrial warehouse pallet racking system.

- Professional Installation: This is highly recommended to ensure your racking is level, plumb, and compliant with manufacturer specifications and local building codes.

- Level and Plumb: On uneven floors, shims are used to make sure the racks stand straight.

- Anchor Bolts: These are vital for fastening the footplates to your concrete floor for stability.

- Routine Maintenance Checks: Encourage staff to report bent beams, dislodged components, or damaged floor anchors.

- Repairing Damage: Any damage must be assessed by an expert. Repairs should only use approved parts and methods.

Installing heavy-duty or complex systems often requires specialized rigging services. Sky Point Crane, serving Pennsylvania, Ohio, West Virginia, and Maryland, has the expertise and equipment for precise material handling. Our 3D Lift Planning ensures every component is placed safely and accurately.

Frequently Asked Questions about Pallet Racking

Here are the answers to what our clients in Pennsylvania, Ohio, West Virginia, and Maryland ask most frequently about industrial warehouse pallet racking.

How do you calculate pallet rack load capacity?

Calculating load capacity is critical for safety. It involves two limits: the capacity of your load beams per level and the total capacity of your upright frames. Your working limit is always the lower of these two values.

- Beam Capacity is determined by its length (shorter is stronger) and face size (a taller face supports more weight).

- Upright Frame Capacity depends on its height, depth, and the vertical distance between beam levels. Importantly, greater spacing between beams reduces the frame’s overall capacity.

Always consult the manufacturer’s load charts and ensure compliance with Rack Manufacturers Institute (RMI) standards. For complex configurations, have a qualified engineer review your setup.

What is the difference between pallet racking and shelving?

Industrial warehouse pallet racking is a heavy-duty system designed to store palletized goods accessed by forklifts. It features wide bays and high load capacities for bulk storage and mechanical handling.

Industrial shelving, in contrast, is for lighter, smaller, non-palletized items that are picked by hand. It has smaller bays and lower weight capacities, typically found in parts rooms or picking areas.

The key distinction is the load type (palletized vs. loose items) and access method (forklift vs. manual picking).

What are the latest trends in pallet racking technology?

The warehouse industry is evolving, and industrial warehouse pallet racking is changing with it. Key trends include:

- Automation Integration: Racking is increasingly the foundational structure for Automated Storage and Retrieval Systems (AS/RS), where robotic pickers and automated forklifts maximize productivity.

- Safety Innovations: Advanced impact protection, real-time load monitoring to prevent overloading, and improved seismic designs are becoming more common.

- Modular Designs: Flexibility is key. Modular racking can be reconfigured as business needs change, offering better long-term value.

- Warehouse Management Software (WMS): WMS integration optimizes storage locations, tracks inventory, and manages picking processes to improve efficiency.

- Sustainability: A growing focus on using recycled materials and designing systems that can be reconfigured or expanded rather than replaced reduces waste.

The bottom line is that modern industrial warehouse pallet racking is an intelligent, adaptive system that integrates with the technology driving modern logistics.

Optimize Your Storage and Boost Efficiency

We’ve covered how industrial warehouse pallet racking is much more than just metal frames—it’s a foundational tool for a thriving business. Investing in the right system is a strategic choice that boosts your entire operation.

A well-designed racking system offers fantastic benefits. First is Space Maximization; you can double or triple your storage capacity by using vertical space. This leads to an Improved Workflow, as an organized warehouse means faster picking, less travel for forklifts, and smoother inventory movement. A proper system also means Improved Safety, drastically reducing accidents and product damage. All these benefits add up to a solid Long-Term ROI. The initial investment pays off through gains in efficiency, lower operational costs, and a safer workplace.

Ready to take your warehouse to the next level? For comprehensive industrial storage planning and execution, explore our Industrial Storage services. Our team at Sky Point Crane brings expertise in heavy material handling and project management to businesses across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. We’re here to ensure your warehouse optimization project is handled with precision and care from start to finish. Let us help you lift your business to new heights!