Why Smart Industrial Tool Storage Solutions Matter for Your Operation

Industrial tool storage solutions are systems designed to organize, protect, and secure tools and equipment in workshops, manufacturing facilities, and job sites. Here’s what you need to know:

Quick Answer: Types of Industrial Tool Storage Solutions

| Storage Type | Best For | Key Features |

|---|---|---|

| Modular Cabinets | Stationary workshops | 150-400 lb drawer capacity, customizable |

| Rolling Tool Carts | Mobile job sites | Heavy-duty casters, portable access |

| Heavy-Duty Chests | Large tool collections | Multi-drawer systems, secure locks |

| Shelving Systems | Parts and equipment | High-density storage, adjustable |

| Workbenches | Active work areas | Integrated drawers, power outlets |

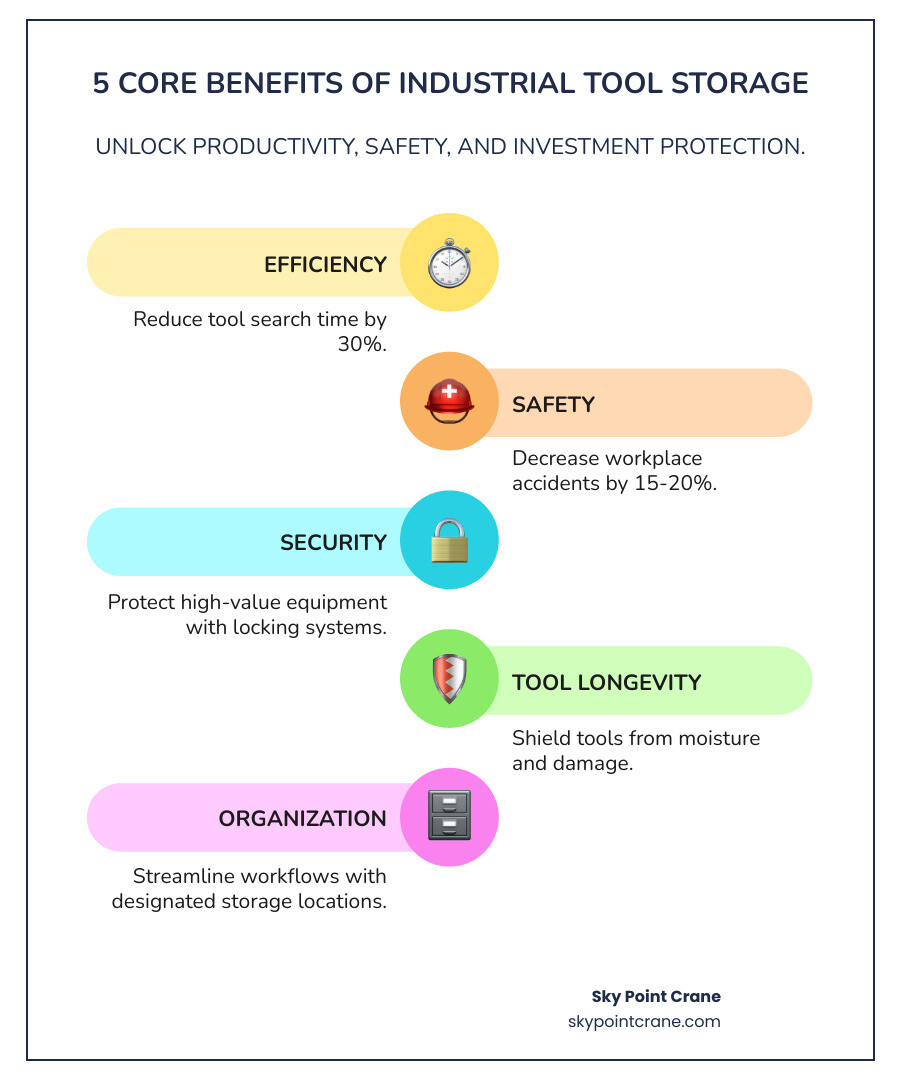

Disorganization in your workspace isn’t just an inconvenience—it’s costing you money. Workers spend up to 30% of their time searching for misplaced tools, and improperly stored equipment leads to a 15-20% increase in workplace accidents. When tools aren’t secured, they’re exposed to damage from moisture, dust, and physical impact, shortening their lifespan and forcing premature replacement.

The industrial tool storage market is projected to grow at 5.5% annually through 2028, driven by companies recognizing that proper storage isn’t an expense—it’s an investment in efficiency, safety, and tool longevity.

Whether you’re managing a construction site, running a manufacturing facility, or overseeing a rigging operation, the right storage system transforms chaos into control. It means your crew spends less time hunting for the right wrench and more time getting the job done. It means fewer trip hazards and better compliance with safety standards. And it means your valuable equipment stays protected and ready to perform.

I’m Dave Brocious, and through decades of building effective teams and solving operational challenges in demanding industrial environments, I’ve seen how industrial tool storage solutions directly impact project efficiency and safety. At Sky Point Crane, we understand that organized, accessible equipment is fundamental to delivering the responsive, reliable service our customers depend on.

Simple guide to industrial tool storage solutions:

Why Effective Tool Storage is a Game-Changer for Productivity and Safety

In demanding industrial environments across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, every second counts, and safety is paramount. That’s why we champion effective industrial tool storage solutions. They’re not just about tidiness; they’re about revolutionizing how your team operates, boosting both productivity and safety.

When your tools are organized, clean, and easily accessible, we see a ripple effect of positive changes. We’re talking about tangible improvements that impact your bottom line and the well-being of your crew.

Boosts Operational Efficiency

Imagine a world where your technicians don’t spend a quarter of their day playing hide-and-seek with a wrench. Sounds like a dream, right? Well, with proper industrial tool storage solutions, it becomes a reality. Studies show that proper tool organization can reduce tool search time by up to 30%, directly translating to increased productivity. This isn’t just anecdotal; it’s a measurable gain.

When every tool has its designated home, your workflow becomes streamlined. This aligns perfectly with lean manufacturing principles and the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), fostering an environment where tasks are completed faster and with fewer interruptions. Our teams, whether on a rigging site or in our maintenance shops, benefit immensely from knowing exactly where everything is. It means less downtime and more uptime for critical projects.

Creates a Safer Work Environment

A cluttered workspace is a dangerous workspace. Misplaced tools are notorious for creating trip hazards, and improperly stored sharp or heavy items pose significant risks. Investing in robust industrial tool storage solutions can lead to a 15-20% reduction in workplace accidents related to misplaced or improperly stored tools. That’s a statistic we can all get behind.

Consider the secure storage of sharp tools in a dedicated drawer or the proper handling of heavy rigging equipment on specialized shelving. This isn’t just about preventing cuts and bruises; it’s about minimizing the risk of serious injuries. By reducing clutter, we create clear pathways and safer working conditions for everyone on site. Our commitment to safety extends to every aspect of our operations, and that absolutely includes how we manage our tools. You can learn more about our commitment to safety here. For more general information about industrial storage, we have resources for that too.

Protects Your Investment

Tools are a significant investment, especially the specialized equipment we use in crane and rigging operations. Leaving them exposed to the elements, or simply piled up, invites damage from moisture, dust, and physical impact. High-quality industrial tool storage solutions are designed to prevent this. They protect your tools, extending their lifespan and ensuring they’re always in prime condition.

We’re talking about features like robust steel construction, sealed drawers, and secure locking mechanisms that safeguard your valuable assets from environmental degradation, accidental damage, and even theft or loss. When you invest in a quality tool, you want it to last. Proper storage is the best insurance policy against premature wear and tear, ensuring that your tools are always ready to perform.

A Guide to the Types of Industrial Tool Storage Solutions

Just as every job requires the right tool, every workspace demands the right storage solution. The market offers a diverse range of industrial tool storage solutions, each designed to address specific needs, from maximizing floor space to enhancing mobility. Understanding these types is the first step toward optimizing your operations.

Stationary Storage: Cabinets and Shelving

For fixed workspaces like workshops, maintenance bays, or tool cribs, stationary storage provides robust, long-term organization.

-

Industrial Cabinets: These are the workhorses of stationary storage. We’re not talking about your kitchen cabinets here; these are heavy-duty, often made from thick-gauge steel, and designed to withstand the rigors of an industrial environment. Many feature modular drawer cabinets, which are fantastic for high-density storage of tools and small parts. For example, some modular drawer systems boast a 400-lb capacity per drawer, designed for evenly distributed loads and often featuring dividers and partitions. Brands like Rousseau offer incredibly durable and flexible modular cabinets, renowned for their heavy-duty construction and timeless look. They even offer a product configurator to help you choose the right dimensions, options, and colors. These cabinets can be outfit with lockable drawers for extra security, which is paramount for valuable tools. We often use industrial cabinets to keep our specialized equipment safe and organized.

-

Heavy-Duty Shelving: When you need to store larger items, bins, or supplies, heavy-duty shelving systems are indispensable. These are often adjustable, allowing for flexible configurations to accommodate items of varying sizes. They are critical for maximizing vertical space and keeping bulkier equipment off the floor. Our own operations, especially when setting up temporary or long-term storage for project components, rely on robust shelving. If you’re looking for comprehensive solutions, we also offer industrial racking installation services.

-

Wall-Mounted Systems: For frequently accessed tools or to free up floor space, wall-mounted systems like pegboards, tool boards, or wall cabinets offer excellent visibility and accessibility.

Mobile Storage: Carts and Rolling Toolboxes

When the work comes to the tools, or the tools need to follow the work, mobile storage solutions are invaluable.

-

Tool Carts: These are designed for portability within a workspace. Our mechanics often use tool carts to bring frequently used tools directly to a crane undergoing maintenance. They come in various sizes, from compact models for a few hand tools to larger, multi-drawer units with integrated work surfaces. Key features include heavy-duty casters (some rated up to 900 lbs each, or even 1,200 lbs for upgraded spring-loaded options) with integral brakes, ensuring stability when in use and easy maneuverability when needed.

-

Rolling Cabinets: These are essentially larger, more robust versions of tool carts, often forming the base of a tool chest system. They provide substantial storage capacity and a degree of mobility, perfect for moving an entire toolkit across a workshop or to different job stations within a facility. Many come with strong steel frames (e.g., 11-gauge or 14-gauge steel) and high-capacity drawers.

-

Jobsite Boxes: These rugged, secure boxes are built to withstand harsh outdoor conditions and provide secure storage for tools on construction sites. They are typically heavy-duty steel, often with piano-style hinges and advanced locking mechanisms, making them difficult to break into. They are essential for protecting tools from theft and weather on active project sites.

Integrated Solutions: Workbenches and Workstations

For a seamless blend of workspace and storage, integrated solutions offer efficiency and convenience.

-

Workbenches with Built-in Drawers: These provide a dedicated work surface combined with immediate access to tools and parts. They often feature multiple drawers, cabinets, and sometimes even pegboard backsplashes for additional hanging storage. Many industrial workbenches come with durable tops made of stainless steel, rubberwood, or bamboo, and can include integrated power strips and USB ports, changing them into complete work hubs. This is particularly useful in fabrication areas or for detailed repair work.

-

Workstations: More comprehensive than a simple workbench, a workstation might include overhead cabinets, lighting, and specialized tool storage custom to specific tasks. These are designed to optimize a particular area for maximum productivity and ergonomic comfort. They are a critical component of efficient commercial storage solutions in many industrial settings.

Key Features to Look For When Selecting Your Storage

Choosing the right industrial tool storage solutions is like selecting the right crew for a complex lift: you need to consider strength, reliability, and specialized capabilities. It’s an investment, and we want to ensure you’re making an informed decision for the long haul.

| Duty Grade | Steel Gauge | Drawer Slide Capacity | Total Load Capacity | Common Use |

|---|---|---|---|---|

| Standard Duty | 21-gauge | 50 lb.+ soft-close | 1,500 lb.+ | Home workshops, light commercial |

| Heavy Duty | 20+ gauge | 120 lb.+ soft-close | 2,500 lb.+ | Professional garages, medium industrial |

| Professional Duty | 16-gauge | 220 lb.+ soft-close | 6,000 lb.+ | Heavy manufacturing, demanding industrial |

Material, Durability, and Capacity

The foundation of any good storage solution lies in its construction.

- Steel Gauge: This is a critical indicator of durability. Lower gauge numbers mean thicker, stronger steel. For industrial applications, we typically look for 16-gauge (Professional Duty) or 20+ gauge (Heavy Duty) steel for tool chests and cabinets. Even Standard Duty starts around 21-gauge. This heavy-duty construction ensures the unit can withstand the knocks and heavy loads of a busy industrial environment.

- Welded Construction: Look for fully welded steel components. This provides superior structural integrity compared to bolted or riveted alternatives, ensuring the cabinet can handle significant weight and abuse over time.

- Powder-Coat Finish: A high-quality powder-coat finish, like AKZO Nobel, not only provides a sleek appearance but also offers excellent resistance to scratches, chemicals, and corrosion, protecting your investment from harsh industrial conditions. Some even come with anti-bacterial properties, like Germ Guard Active Technology, which is a nice bonus for hygiene.

- Drawer Load Ratings: This specifies how much weight each drawer can safely hold. While standard drawers might handle 50-100 lbs, professional-grade drawers can often support 150 lbs, 300 lbs, or even 400 lbs (for single slides) or up to 600 lbs (for double slides) of evenly distributed weight. This is crucial for storing heavy hand tools, power tools, or specialized parts.

- Caster Capacity: For mobile units, the casters are vital. They should be heavy-duty, often rated for 900 lbs each, with upgraded options reaching 1,200 lbs per caster. Look for silent, resistant casters with integral brakes that won’t mark your floors.

- Lifetime Warranty Importance: A robust warranty, especially a lifetime guarantee on drawer sliding systems, speaks volumes about a manufacturer’s confidence in their product’s durability and quality. This provides peace of mind for your long-term investment.

Security and Accessibility

Protecting valuable tools and ensuring quick access are two sides of the same coin.

- Central Locking Systems: A single lock that secures all drawers or compartments simultaneously is a must-have. This can range from traditional keyed locks to more advanced electronic locks.

- Smart Locks (NFC/Bluetooth): The future is now! Advanced features like smart locks, such as Rousseau’s L100, use NFC (Near Field Communication) and Bluetooth technology for keyless access. This not only eliminates the hassle of lost keys and forgotten codes but can also provide an audit trail of who accessed tools and when, enhancing inventory management and accountability.

- Anti-Jemmy Doors: For high-security cabinets, look for features like anti-jemmy doors with concealed fixings and continuous weld steel construction. These are designed to deter forced entry, offering an improved level of security for high-value equipment or confidential materials.

- Full-Extension Drawer Slides: These allow drawers to open completely, providing full visibility and easy access to every item, even those at the very back. No more rummaging!

- Ball-Bearing Mechanisms: Smooth-glide ball-bearing slides ensure that even heavily loaded drawers open and close effortlessly, reducing strain on workers and extending the life of the unit.

Modularity and Customization

The demand for modular and customizable industrial tool storage solutions is increasing, driven by the need for flexibility and space optimization.

- Configurable Components: Modular systems allow you to choose dimensions, drawer configurations, and accessories to build a storage unit perfectly suited to your needs. This flexibility means your storage can evolve with your operational requirements.

- Stackable Units: Some systems are designed to stack, allowing you to build vertical storage solutions that maximize floor space, especially beneficial in smaller workshops or crowded industrial settings.

- Common Accessories: The right accessories can transform a basic cabinet into a highly organized system:

- Drawer dividers and partitions: Essential for segmenting drawers and keeping small parts separated.

- Protective foam inserts: Ideal for sensitive tools, providing custom-fit cushioning and preventing movement.

- Plastic bins: Great for organizing fasteners, fittings, and other small components within drawers.

- Pegboard hooks: For wall-mounted systems or workbench backsplashes, allowing tools to be hung for quick visual access.

Tailoring Your Setup: Customization and Industry-Specific Needs

One size rarely fits all, especially in the diverse world of industrial operations across Western PA, Ohio, WV, and Maryland. The beauty of modern industrial tool storage solutions lies in their adaptability. Customization is not just a luxury; it’s a strategic advantage.

The Power of Customization

Personalized storage isn’t just about aesthetics; it’s about optimizing every cubic inch of space and every second of your team’s time.

- Drawer Organization: Beyond basic dividers, advanced drawer organization includes specialized inserts for specific tool types (e.g., wrench organizers, socket trays). This ensures that every tool has a precise place, reducing search time and preventing damage from tools rattling against each other.

- Color-Coding for Efficiency: A simple yet powerful customization is color-coding. Different colors for drawers or cabinets can signify different departments, tool sets, or project stages, making identification instant and reducing errors.

- Design Your Own Storage: Many manufacturers, like Rousseau Metal, offer online product configurators. This allows you to interactively choose dimensions, options, and colors to create a storage solution that perfectly matches your space and needs. You can explore this concept with their product configurator.

- Foam Inserts for Sensitive Equipment: For high-value or delicate instruments, custom-cut foam inserts provide unparalleled protection. They cradle each tool securely, preventing movement, scratches, and impact damage. This is critical for calibration tools or specialized electronic equipment.

- Maximizing Space: Customization allows you to use awkward spaces, integrate storage into existing structures, and create multi-functional units that serve both as storage and workspace.

Choosing the right industrial tool storage solutions for Your Sector

The ideal storage solution is heavily influenced by the industry and specific application.

- Automotive Needs: Auto repair shops often require extensive rolling cabinets, tool carts, and workbenches with integrated storage for a vast array of hand tools, power tools, and diagnostic equipment. Durability and mobility are key.

- Manufacturing Facilities: These environments benefit from modular drawer cabinets for small parts and tooling, heavy-duty shelving for raw materials and finished goods, and specialized solutions for CNC tools or bending equipment. The focus is on systematic organization and high-density storage.

- Aerospace Requirements: Precision and cleanliness are paramount. Aerospace facilities often use highly organized, dust-free cabinets, custom foam inserts for delicate instruments, and secure storage for calibrated tools, often with advanced tracking systems.

- Rigging and Heavy Equipment Industries: This is where we truly shine and where our expertise comes into play. For our crane and rigging operations across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, industrial tool storage solutions must be exceptionally robust and secure. We need solutions that can handle heavy-duty tools, lifting accessories, chains, slings, and specialized equipment like load cells and laser alignment tools.

- Durability: Our tools endure heavy use and challenging environments. Storage must match this resilience.

- Portability: While some tools stay in our shops, many need to travel to job sites. Jobsite boxes and heavy-duty tool carts are essential for mobile teams.

- Security: High-value rigging gear requires secure, lockable storage to prevent loss and ensure accountability.

- Organization: When you’re managing a critical lift, you can’t afford to waste time searching for a specific shackle or a specialized wrench. Organized storage ensures our NCCCO certified operators and riggers have immediate access to what they need.

- For our specialized gear and equipment that remains in our facilities, indoor industrial storage solutions are designed to protect and organize everything, from smaller components to larger rigging accessories.

Frequently Asked Questions about Industrial Tool Storage

We often get questions about optimizing storage in industrial settings. Here are some of the most common ones we hear:

How much weight can industrial tool drawers typically hold?

Drawer capacity varies widely based on the duty rating, from around 50-100 lbs for standard units to over 400 lbs per drawer for heavy-duty professional cabinets. Always check the manufacturer’s specifications for load ratings. For example, some Extreme Tools EX Series drawers with double slides can hold up to 600 lbs, while Rousseau mobile cabinets can boast 400 lbs per drawer. This capacity is usually based on an evenly distributed load and often recommends using partitions and dividers to manage the weight effectively.

What is the difference between modular and standard tool cabinets?

Standard cabinets have a fixed configuration. They come as a complete unit with a set number of drawers, shelves, and dimensions that cannot be easily changed. Modular cabinets, on the other hand, allow you to customize the size, number of drawers, and accessories, and can often be reconfigured or added to over time, offering greater flexibility. This means you can start with a basic setup and expand it as your needs grow, or re-arrange components to suit a new workflow. The demand for modular and customizable solutions is increasing because they offer superior flexibility and space optimization in dynamic industrial environments.

How do advanced features like smart locks improve tool storage?

Smart locks provide keyless access via NFC (Near Field Communication) or Bluetooth, create an audit trail of who accessed tools and when, and can improve security by eliminating physical keys that can be lost or copied. This is crucial for high-value tool and inventory management. For instance, Rousseau’s L100 Smart Lock is highlighted for its keyless convenience and the security it offers. Beyond just convenience, these systems can integrate with inventory management software, giving you real-time data on tool usage and location, which is invaluable for accountability and preventing loss, especially for expensive or specialized equipment.

Conclusion

We’ve explored how a strategic approach to industrial tool storage solutions can fundamentally transform your operations. From boosting efficiency by drastically cutting down tool search time to significantly enhancing workplace safety and protecting your substantial investment in tools, the benefits are clear and measurable.

The right storage system isn’t just a container; it’s a critical component of a productive, safe, and organized industrial environment. It’s about choosing durable materials, ensuring robust security, and embracing modularity and customization to meet your unique needs. Whether it’s heavy-duty cabinets for a manufacturing floor or mobile solutions for a dynamic rigging job site, the market offers sophisticated options that can be custom to precision.

At Sky Point Crane, we understand the rigorous demands of industrial environments across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, and the absolute importance of organized, secure equipment. Just as we carefully plan every lift with 3D Lift Planning and manage projects for optimal safety and efficiency, we advocate for the same level of precision in your tool management. For comprehensive industrial storage solutions and expert handling of your heavy equipment, explore our services. We’re here to help you revolutionize your workspace for peak performance.