Why Boomtruck Cranes Are Essential for Modern Construction

In the world of modern construction, efficiency is everything. Projects demand equipment that is not only powerful but also agile and adaptable. This is where Boomtruck Cranes shine. As truck-mounted hydraulic cranes, they masterfully combine mobility, versatility, and cost-effectiveness into a single, indispensable piece of equipment. Unlike larger, more cumbersome stationary or all-terrain cranes, boom trucks can travel at highway speeds between job sites and be set up in a fraction of the time. This makes them the ideal solution for a vast range of lift jobs, particularly those under 40 tons.

Quick Answer: What Makes a Great Boomtruck Crane?

A superior boom truck is defined by its ability to meet the specific demands of a project with precision and reliability. Heres a closer look at the core features that make them so effective:

- Lifting Capacity: While capacities can vary, most commercial boom trucks operate in the 17 to 50-ton range. This sweet spot covers a huge percentage of common construction tasks, from lifting bundles of roofing materials to placing heavy-duty HVAC systems, without the overkill and expense of a larger crane.

- Boom Length: With typical main boom lengths ranging from 100 to 155 feet, these cranes offer substantial vertical and horizontal reach. For jobs requiring even greater heights, optional jib extensions can be added, providing the extra reach needed for tasks like setting communication antennas or working on taller structures.

- Mobility: The fundamental advantage of a boom truck is that it’s built on a commercial truck chassis. This means it drives like a standard truck, requires no special transport permits or pilot cars, and can steer city streets and highways with ease, dramatically reducing transportation time and costs between jobs.

- Setup Time: Time is money on a construction site. A boom trucks hydraulic outriggers can be deployed and leveled in minutes, allowing work to begin almost immediately upon arrival. This rapid mobilization and demobilization is a stark contrast to the hours or even days required to assemble a tower crane.

- Applications: Their adaptability makes them perfect for a diverse set of industries. You’ll see them expertly handling rooftop equipment placement, delicate sign and banner installations, critical utility line maintenance, tree care and removal, and the efficient loading and unloading of building materials.

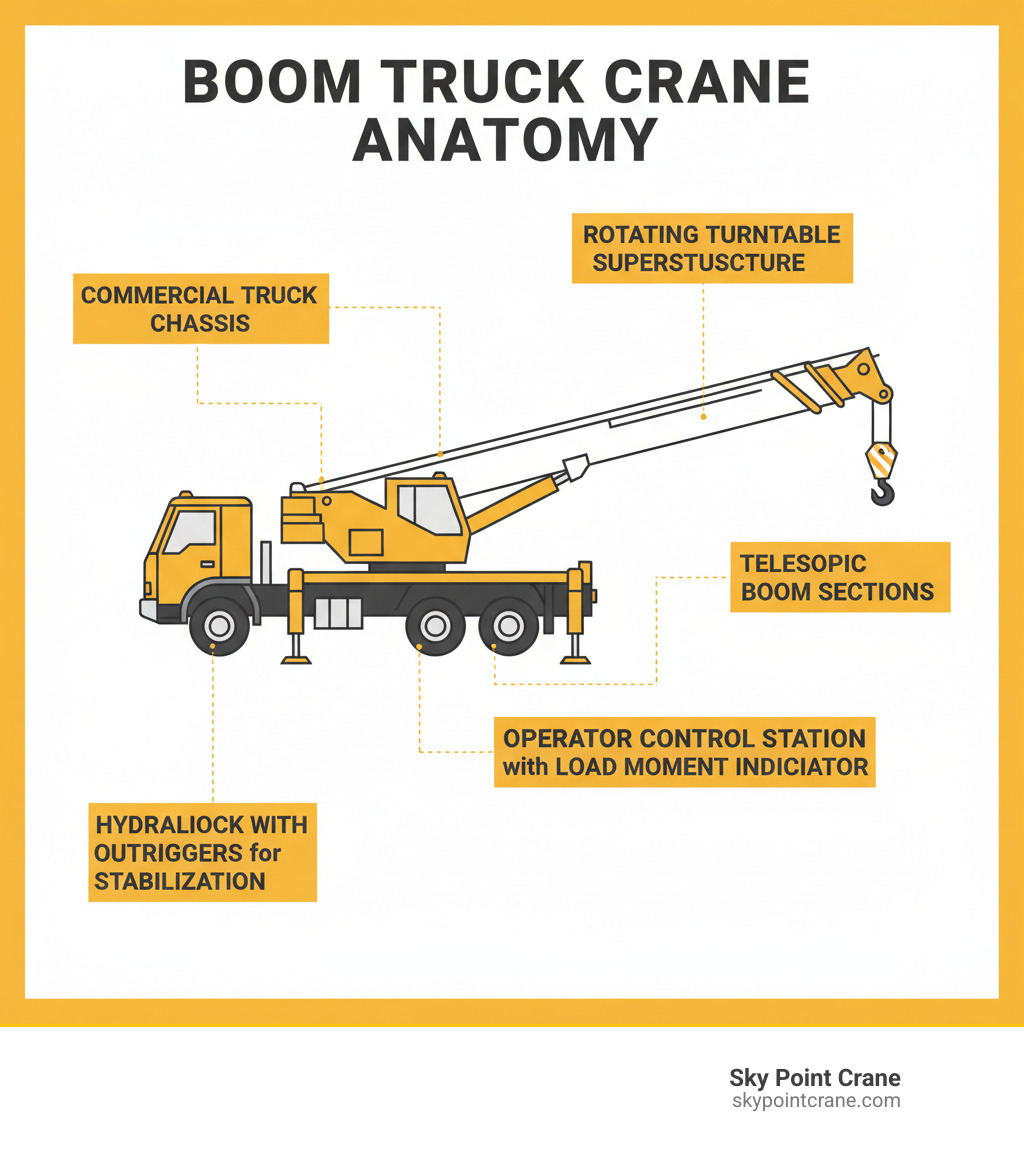

A boom truck consists of a rotating superstructure (turntable) that allows for a full 360 swing, a multi-section telescopic boom that extends and retracts hydraulically, and an operator control station, all mounted on a road-legal commercial truck chassis. For safe operation, the crane relies on a system of outriggers that extend from the chassis to create a wide, stable base for lifting, lowering, and swinging loads at various radii.

Key advantages over traditional cranes:

- Highway-speed travel between job sites: Eliminates the need for costly and slow third-party transportation.

- Smaller footprint for confined work areas: Can set up in tight urban environments, alleyways, or crowded construction sites where larger cranes cannot fit.

- Lower transportation costs: No need for special permits, escort vehicles, or dedicated hauling equipment.

- 360 rotation capability: Provides full-circle access to the work area from a single setup point.

- Quick mobilization and demobilization: Minimizes downtime and allows crews to complete more work in a single day.

Across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, this combination of speed and compact setup translates directly into productivity. Urban infill projects with narrow streets, school or hospital rooftop replacements on tight timelines, and maintenance outages in industrial plants all benefit from a boom trucks ability to arrive, set outriggers, make precise picks, and move on. In a single day, one machine can service multiple sites, helping you meet schedule milestones without staging a large crane fleet.

Its also an excellent tool for traffic- and public-facing work. With proper planning and control, a boom truck can operate from a constrained curb lane or alley to set signage, hoist glazing panels, or place mechanical equipment, all while keeping your work zone as compact as possible and minimizing disruptions in dense areas.

I’m Dave Brocious, and with over 30 years in the crane and construction equipment industry, I’ve helped countless contractors across Western Pennsylvania find the perfect Boomtruck Cranes for their unique project needs. At Sky Point Crane, our philosophy isn’t just about renting equipment; it’s about providing solutions. We focus on understanding your challenges to deliver equipment that guarantees safety, efficiency, and unwavering reliability when you need it most.

While boom trucks handle the majority of everyday lifting, there are times when another crane type is the safer, faster choiceike very heavy picks beyond typical boom truck capacity, extreme radii, or soft, uneven terrain. When thats the case, well tell you, and well put the right machine on your site. Our team supports projects end-to-end with planning, including engineered lift plans and 3D Lift Planning, so you start each pick with clarity and confidence. Learn more about how we plan and execute lifts at https://skypointcrane.com/crane-services/.

To zero in on the right boom truck for your job, start with a few essentials:

- What is the heaviest load and its exact weight?

- What is the required pick radius and the set height/elevation?

- How constrained is the setup area (lane width, alley, or lot)?

- What are the ground conditions and bearing capacity at the outrigger pads?

- Are there overhead obstructions (power lines, canopies) or access restrictions?

Answering these questions upfront lets us match capacity, boom length, and setup configuration to your site, so you get a safe, efficient lift on the first trip.

Simple guide to Boomtruck Cranes terms:

Types of Boom Trucks: Telescopic and Their Applications

When you’re sourcing the right lifting equipment, understanding the different types of Boomtruck Cranes can save you significant time, money, and on-site headaches. While several variations exist, the two main categories you’ll encounter are telescopic boom cranes and knuckle boom cranes. Both offer incredible versatility, but they are engineered for very different tasks. For construction, utility, and installation projects across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, the telescopic boom crane is the undisputed workhorse.

While knuckle boom cranes (or articulating cranes) are excellent for loading and unloading materials close to the truck bed, their “knuckling” boom is designed for maneuverability in tight spaces at lower elevations. In contrast, when the job requires significant height and precise placement, the telescopic boom crane is the superior choice.

Telescopic Boom Cranes

Telescopic boom cranes are engineered for strength, reach, and operational simplicity. Imagine a classic telescope—that’s the fundamental principle behind their design. The boom is made of several nested steel sections that extend and retract hydraulically. This allows the crane to achieve impressive vertical reach for lifting tasks while maintaining a compact, road-ready profile during transport.

The defining feature that makes these cranes so popular is their straight-line lifting capability. When a project requires placing a multi-ton HVAC unit on a four-story roof, setting heavy wooden trusses for a new building, or installing a company sign high above a busy street, a telescopic boom crane provides the direct vertical access needed to execute the job with maximum efficiency. There is no complex articulation to steer; instead, the operator uses smooth, predictable hydraulic controls to guide the load directly to its destination. This direct path makes precise positioning far easier and safer, a critical factor when working near existing structures or personnel. The skill of a certified operator is paramount in leveraging this precision, which is why standards set by organizations like the National Commission for the Certification of Crane Operators (NCCCO) are so important in ensuring safe and effective crane operation.

The true value of telescopic boom cranes is revealed in their versatility across diverse job sites. Their ability to travel at highway speeds makes them incredibly cost-effective, as a single crane can service multiple locations in one day without the logistical burden of larger cranes. Whether you’re engaged in commercial building erection, ongoing utility maintenance, or specialized sign installation, these machines adapt seamlessly to your project’s demands.

Here’s a more detailed look at what sets telescopic boom cranes apart:

| Attribute | Description |

|---|---|

| Reach | With main booms extending up to 155 feet and optional jib attachments for even greater height, these cranes can access work areas on multi-story buildings and other tall structures with ease. |

| Lifting Style | The straight-line, direct vertical lifting path is ideal for placing loads with high precision. This “up-and-over” capability is essential for rooftop work and setting materials over obstacles. |

| Precision | Advanced hydraulic systems allow for incredibly smooth and controlled boom extension, retraction, and rotation. This enables operators to position loads with pinpoint accuracy, minimizing the risk of damage. |

| Common Uses | Their design is perfectly suited for setting roof trusses, HVAC installation, cell tower maintenance, sign work, lifting rebar cages, and hoisting general building materials to upper floors. |

For contractors who need reliable, powerful lifting capacity without the immense cost and logistical complexity of larger all-terrain or crawler cranes, the telescopic boom crane consistently delivers performance where it counts. If you’re considering a telescopic boom truck crane for your next project, or if your work requires the added personnel-lifting flexibility of a boom truck with bucket for utility or maintenance tasks, understanding these core capabilities is the first step in matching the right equipment to your job.

At Sky Point Crane, we’ve deployed these machines for everything from simple, routine maintenance lifts to complex, multi-stage construction projects. The key to success is always choosing the right capacity and configuration for your specific lift—a process our team of experts can guide you through to ensure your project is completed safely and efficiently.