Why Cold Storage Pallet Racking Demands Special Attention

Cold storage pallet racking is a specialized shelving system designed for sub-zero temperatures. It maximizes storage density in refrigerated and frozen environments while handling challenges like extreme cold (down to -30°F), higher forklift impact risk, and the need for energy efficiency and maximum space utilization.

Key Requirements for Cold Storage Pallet Racking:

- Material durability – Must resist the ductile-brittle transition at 0°F and handle 40% more forklift impacts than ambient warehouses.

- High-density configuration – Reduces cubic footage to cool, cutting energy costs.

- Corrosion resistance – Galvanized finishes protect against moisture and temperature fluctuations.

- System compaction – Mobile racking can increase capacity by 80% while reducing energy bills.

- FIFO or LIFO capability – Supports proper stock rotation for perishable goods.

Operating a cold storage facility is expensive, and with the rising consumption of refrigerated products, maximizing every cubic foot is critical. The challenge is to store more pallets while maintaining cold chain integrity, managing driver safety in freezing conditions, and controlling energy costs.

I’m Dave Brocious. With over 30 years of experience in industrial solutions, I’ve helped facilities optimize their cold storage pallet racking for efficiency and safety. At Sky Point Crane, we understand that proper racking selection and installation are critical to your operational success.

Terms related to cold storage pallet racking:

The Unique Challenges of Cold Environments

Freezer warehouses with temperatures around -20°F demonstrate why cold storage pallet racking is unique. These environments present a perfect storm of challenges that can impact your operation and budget.

Sub-zero temperatures slow forklift operators’ reflexes, making impacts more likely. In fact, cold storage facilities experience roughly 40% more forklift collisions than room-temperature warehouses due to confined spaces, frost, and slick surfaces.

This is made more critical by the ductile-brittle transition. According to the Rack Manufacturer’s Institute, steel becomes brittle below 0°F. An impact that would only dent a beam in a warm warehouse could cause a catastrophic failure in a freezer. The Rack Manufacturer’s Institute explains the ductile-brittle transition in detail, and understanding it is vital for cold storage safety.

Energy costs are another major factor. Running refrigeration systems 24/7 is expensive, and cooling empty space from an inefficient racking system is a significant drain on your budget. Finally, maintaining the cold chain is paramount. A break in temperature control can cause product loss and food safety issues. Your racking must support efficient product rotation and quick handling to maintain temperature stability.

These challenges require thoughtful planning and the right equipment. For more insights on optimizing your storage operations, check out our guide on Industrial Storage Solutions.

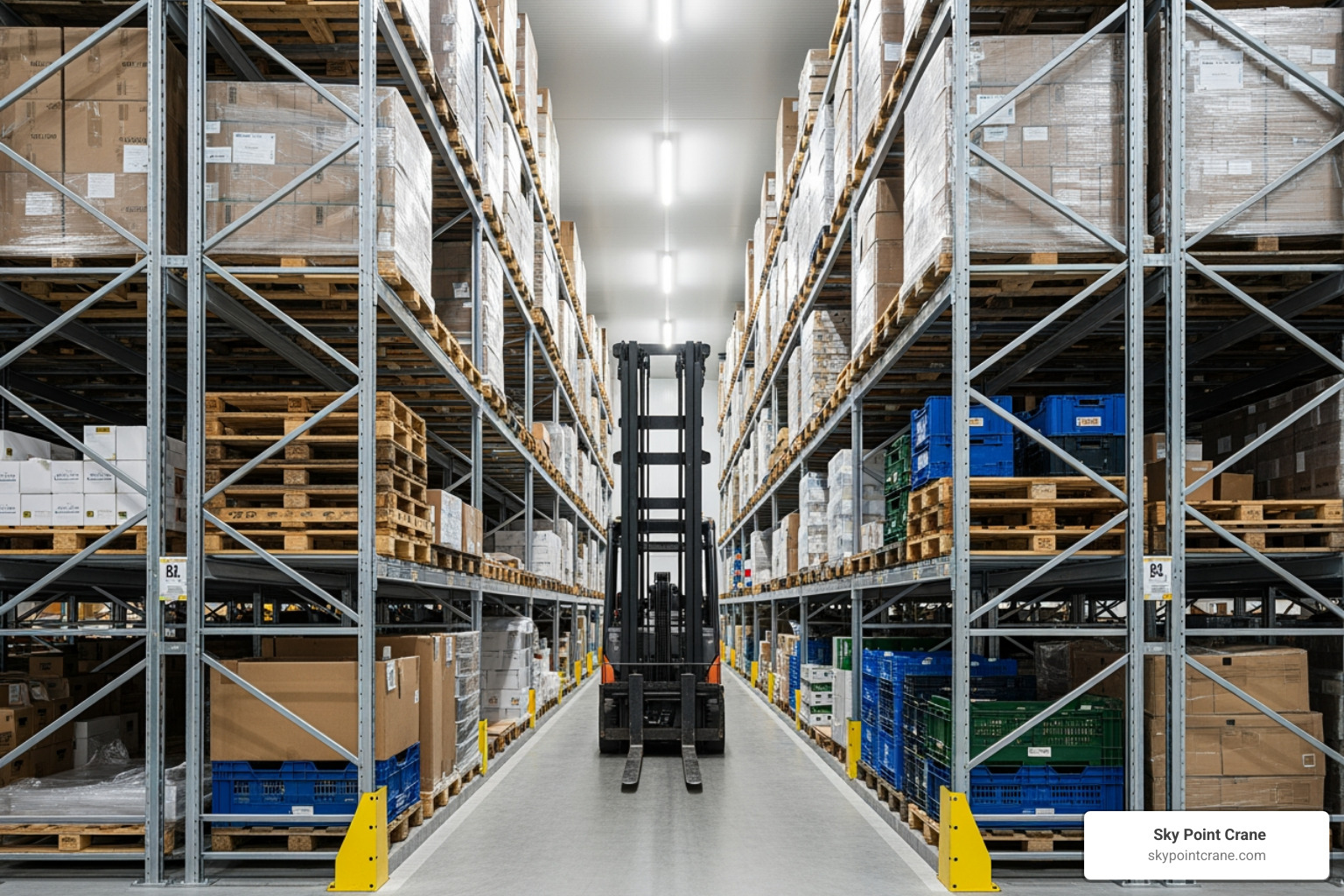

Why Storage Density is Crucial

In cold storage, every square foot costs money daily. Wasted space isn’t just inefficient; it actively drains your budget through energy costs because you pay to cool every cubic foot of air 24/7. By increasing storage density, you fit more pallets into the same refrigerated volume, which means the cost per pallet stored drops significantly.

High-density racking systems are ideal for this. Mobile pallet racking, for instance, can boost storage capacity by up to 80% compared to conventional selective racking. By reducing aisles and consolidating goods, you dramatically cut the volume of air that needs cooling. This leads to significant energy savings as your refrigeration system works more efficiently.

Some mobile systems even offer a “night setting” that closes all aisles when not in use, creating a compact, easier-to-cool mass. This results in lower energy consumption, reduced operating costs, and a faster return on investment.

If you’re exploring options for commercial cold storage, you can Find Commercial Storage Facilities that understand the importance of density and efficiency.

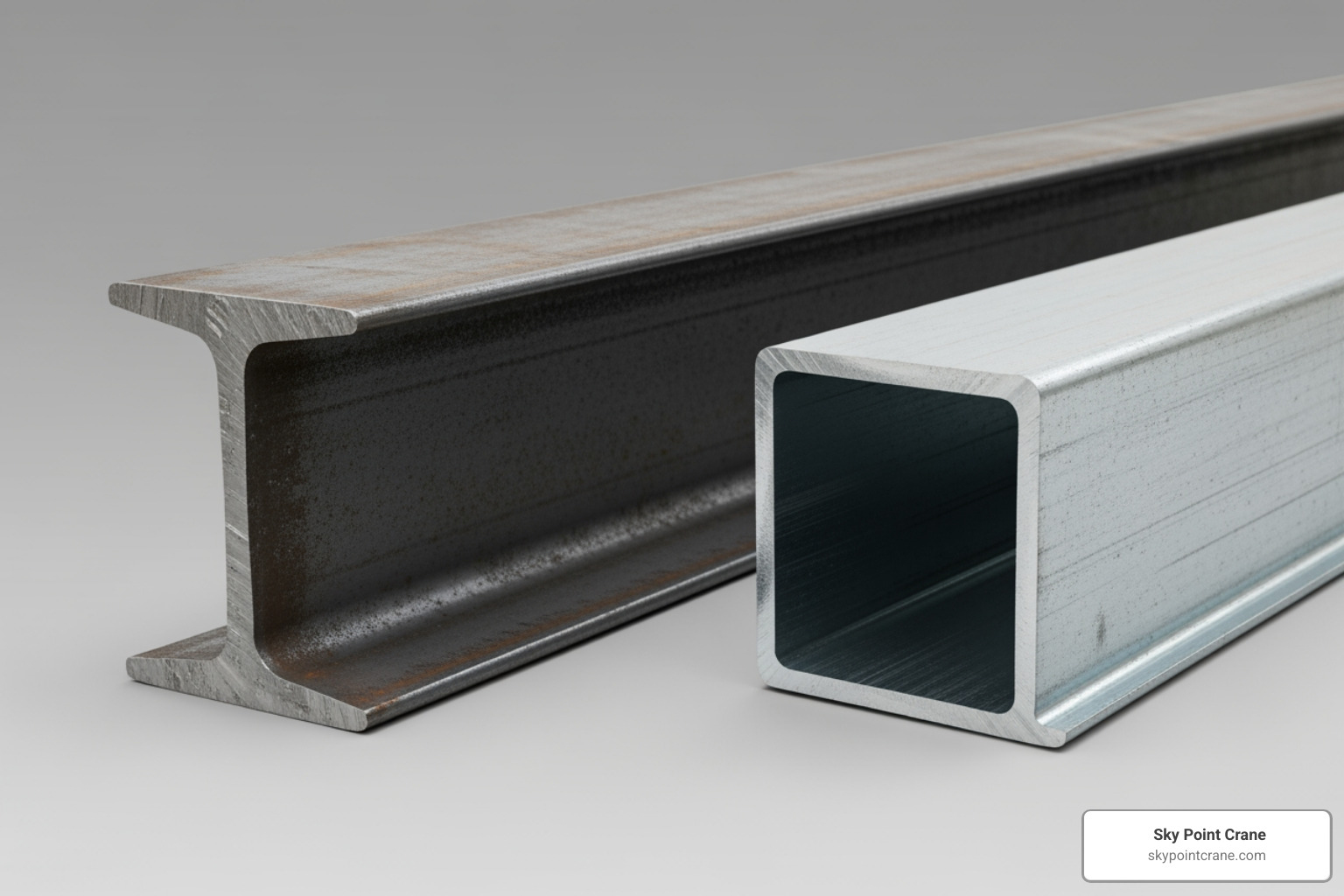

Key Differences in Cold Storage Pallet Racking Materials

The steel used for your cold storage pallet racking is critical. The right material can last for decades, while the wrong one can fail dangerously.

Structural steel is the champion of cold storage. Made from hot-rolled steel with welded components, these racks are extremely durable. For high-turnover facilities with heavy forklift traffic, structural steel’s superior impact resistance is essential, especially in freezers at or below the 0°F ductile-brittle transition point. It’s the best choice for active cold zones with forklifts.

Roll-formed steel is a more budget-friendly and adjustable option. These racks are made by shaping steel sheets and have clip-in connectors. Roll-formed steel is suitable for cold storage areas with only hand-picking and minimal vehicle traffic, where high impact resistance is less of a concern.

Both types, however, require serious corrosion protection. Condensation and temperature swings cause rust. Quality cold storage racking needs either hot-dip galvanizing or a robust paint system. Galvanized finishes are often preferred for their superior, long-lasting protection against moisture and temperature fluctuations in a cold storage facility.

A Guide to Common Cold Storage Pallet Racking Systems

Choosing the right cold storage pallet racking system requires balancing product rotation (FIFO vs. LIFO), storage volume, and accessibility, all while controlling energy costs and ensuring durability. Many facilities use a hybrid approach, combining standard racks for accessible items with high-density systems for bulk storage to maximize the use of valuable cold storage space.

Here’s a comparison of high-density racking systems for cold storage:

| System Type | Density | Selectivity | Cost (Relative) | Ideal Use Case |

|---|---|---|---|---|

| Drive-In/Drive-Thru | Very High | Low | Medium | Storing large quantities of homogeneous products with limited SKUs, LIFO (Drive-In) or FIFO (Drive-Thru) rotation. |

| Mobile Racking | Very High | High | High | Maximizing capacity with 100% selectivity, reducing energy costs, diverse SKUs. |

| Pallet Shuttle | High | Medium-High | High | High-density storage with automated retrieval, suitable for many pallets per SKU, FIFO/LIFO flexibility. |

| AS/RS (Automated) | Very High | High | Very High | Fully automated operations, minimal human presence, high throughput, precise inventory control, energy savings. |

Conventional Racking: Selective Pallet Racks

Selective pallet racking is a common, flexible system offering direct access to every pallet. It’s ideal for facilities with a high number of different products (SKUs) requiring immediate access. The downside is its lower storage density due to wide aisles, which increases the volume of air to be cooled. However, for low-volume, high-SKU inventory, its accessibility is a major advantage. It often serves as a base system combined with other solutions. If you’re looking for versatile storage options, we can help you explore Indoor Industrial Storage options.

High-Density Systems for Maximum Space

To maximize expensive refrigerated space, high-density systems are designed to reduce aisle space and increase storage capacity.

Drive-In & Drive-Thru Racking are ideal for storing large quantities of the same product. Forklifts drive directly into the rack structure. Drive-In systems are Last-In, First-Out (LIFO), while Drive-Thru systems allow for First-In, First-Out (FIFO) rotation, crucial for perishable goods. Both significantly increase storage density.

Push-Back Racking offers high density while allowing different products in each lane. Pallets sit on nested carts on inclined rails. This LIFO system is excellent for operations requiring multiple pick faces, common in the food industry.

Pallet Flow Racks, or gravity flow racks, use angled rollers to move pallets from the loading to the picking side. This guarantees strict FIFO rotation, perfect for perishable goods. By storing pallets several deep, this system reduces aisle space and ensures efficient stock rotation.

Advanced High-Density Solutions

More sophisticated high-density solutions can further revolutionize cold storage operations.

Mobile Pallet Racking (MOVO) places standard racking on mobile bases that run on floor tracks. This design eliminates all but one working aisle, increasing storage capacity by up to 80% compared to selective racking. The compact design reduces the air volume to be cooled, lowering the cost per pallet. These robust systems can support bay loads up to 24 tons and have a ‘night setting’ for added efficiency.

Pallet Shuttle Systems use a semi- or fully-automated cart (a “shuttle”) to move pallets within the racking. A forklift places a pallet on the shuttle, which transports it into a deep storage lane. This prevents forklifts from entering the rack, reducing impact damage and speeding up throughput. Ideal for high-density storage of many pallets per SKU, these systems can operate in temperatures as low as -30°C and support both FIFO and LIFO management.

The Role of Automation (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) are robotic solutions that push the limits of efficiency and safety in cold storage. AS/RS offers several key advantages:

- Reduced Labor in Extreme Cold: Automated warehouses minimize the need for staff in harsh, cold environments, significantly improving worker safety.

- Maximized Space and Height: AS/RS uses tall stacker cranes to build higher and narrower than manual systems, creating incredibly dense storage.

- Significant Energy Savings: With no need for human access, AS/RS allows for smaller aisles, reducing the total volume that needs cooling and saving on energy.

- Improved Accuracy and Productivity: Automation provides precise inventory control, leading to fewer errors and faster operations.

- Reduced Damage: Robotic handling minimizes the risk of forklift impacts and product damage.

However, there are considerations for AS/RS:

- Higher Initial Investment: The upfront cost is substantial, but long-term savings in labor, energy, and reduced damage often provide a strong return on investment.

- Complexity: These advanced systems require specialized knowledge for installation, maintenance, and integration.

Despite the initial cost, the benefits of AS/RS in cold storage—including safety, energy efficiency, and operational excellence—are compelling.

Safety and Design Considerations

Safety and smart design are essential for cold storage pallet racking. The combination of cold temperatures, potentially slick surfaces, and brittle steel demands robust design and comprehensive safety measures. A well-designed system does more than hold pallets; it ensures product preservation, energy conservation, and team safety. Proper design allows for free airflow, which is vital for the uniform cooling needed to protect the cold chain.

Precision installation is also key, as small alignment errors can weaken the structure under cold-stress conditions. At Sky Point Crane, our expert project management and rigging team ensures complex racking systems are installed safely and to specification for long-term reliability across Western Pennsylvania, Ohio, West Virginia, and Maryland.

Safety Considerations for Cold Storage Pallet Racking

In a cold storage facility, safety is a necessity. The mix of freezing temperatures, heavy loads, and moving machinery creates unique risks. Because cold makes steel brittle and can slow driver reflexes, cold storage pallet racking must be exceptionally tough and impact-resistant.

Protective guarding is crucial. This includes Column Protectors, End-of-Aisle Guards, and Row-End Protectors to shield racks from forklift collisions. For certain systems, Safety Gates prevent pallets from falling. All guards must be custom-fitted to your specific rack system and facility layout.

Beyond guards, thorough forklift operator training is vital. Operators must understand how to work safely with specific rack systems in a cold environment. Finally, regular inspections are essential for catching damage early, preventing costly repairs and serious accidents. These steps reduce downtime, cut costs, and create a safer workplace. We’re truly committed to safety, and we invite you to Learn about our commitment to Safety, Health & Environment.

How Racking Design Impacts Energy Efficiency

Your cold storage pallet racking design significantly impacts your energy bill. A smart layout can cut operating costs, while a poor one wastes energy. In cold storage, density is key. A more compact system leads to more energy-efficient cooling, saving money on every cubic meter.

Here’s how smart racking design saves energy:

- Compaction: High-density systems (mobile, drive-in, pallet shuttle) reduce aisles and maximize floor space, shrinking the volume of air that needs cooling and thus saving energy.

- Reduced Air Volume: Every empty cubic foot requires energy to cool. Filling that space with product and reducing aisles directly lowers your energy consumption.

- Aisle Configuration: Narrower aisles in high-density systems reduce exposure to warmer air during loading/unloading, meaning less air needs to be re-cooled.

- Improved Air Circulation: Some designs, like mobile racking, improve the circulation of chilled air. A ‘night setting’ can close aisles to form a solid block, further stabilizing temperature and saving energy.

- Automation: AS/RS operates in tighter spaces, naturally reducing the cooled area and leading to significant energy savings.

A well-planned racking design ensures optimal, even cooling, protecting both your products and your budget.

Frequently Asked Questions about Cold Storage Racking

It’s normal to have questions about cold storage pallet racking, a specialized field with unique demands. Here are answers to some common questions to help you make informed decisions.

How do I choose between structural and roll-formed steel?

The choice between structural and roll-formed steel for your cold storage pallet racking depends on your facility’s traffic and temperature.

Structural steel is the best choice for busy freezer environments (0°F or below) with heavy forklift traffic. Its superior impact resistance is crucial because cold makes steel more brittle (the ductile-brittle transition), increasing the risk of damage from impacts. Its welded construction provides necessary resilience.

Roll-formed steel is a budget-friendly, adjustable option suitable for cooler environments or areas with minimal vehicle traffic, like hand-picking zones. It is less impact-resistant than structural steel, making it a good choice where the risk of forklift collisions is low.

What is the most space-efficient cold storage racking system?

To maximize precious cold storage space, the most efficient cold storage pallet racking systems are mobile pallet racking and Automated Storage and Retrieval Systems (AS/RS).

Mobile pallet racking places racks on tracks, eliminating all but one moving aisle. This can increase storage capacity by up to 80% compared to selective racking. The compact design also reduces the air volume that needs cooling, lowering energy bills.

AS/RS are robotic solutions that maximize space by building higher and narrower than manual systems, achieving extreme storage density. By minimizing the need for human access, they also reduce the cooled volume and improve energy efficiency.

Pallet shuttle systems also offer excellent density by using automated shuttles to store pallets deep within the racking, eliminating the need for forklifts to enter the lanes.

Can you combine different types of racking in one cold storage facility?

Yes, combining different types of cold storage pallet racking is not only common but often the smartest strategy for an optimized operation.

For example, you could use pallet flow racks for perishable products requiring strict First-In, First-Out (FIFO) rotation, and drive-in racking for high-density storage of bulk goods where Last-In, First-Out (LIFO) is acceptable.

You could also integrate selective racking for high-SKU items needing direct access. This hybrid approach tailors the storage solution to different product needs, balancing density, product flow, and energy savings.

Choosing and Implementing Your Ideal System

Choosing and implementing the right cold storage pallet racking system is a strategic decision that impacts your efficiency, energy costs, and product integrity. There is no one-size-fits-all solution; the process must be custom to your specific needs in Western Pennsylvania, Ohio, West Virginia, or Maryland.

To make the best choice, several factors must be considered:

- Inventory Analysis: What are you storing? Consider the quantity, dimensions, weight, and rotation requirements (FIFO or LIFO) of your goods.

- Throughput Requirements: How quickly do products move? High-volume goods may require automation or pallet flow, while slower-moving bulk items are better suited for drive-in or push-back systems.

- Budget Considerations: Look beyond the initial investment to the total cost of ownership, including long-term energy savings and reduced maintenance. Automated systems may have a higher upfront cost but can deliver significant long-term savings.

- Future Growth: Your storage solution should be flexible enough to adapt as your business expands.

- Facility Specifications: We assess your facility’s size, height, and existing infrastructure to create the perfect plan.

The right cold storage pallet racking is vital for maintaining the cold chain. It optimizes cooling, uses durable materials, and facilitates efficient product movement to prevent temperature fluctuations that can lead to product deterioration. A well-chosen system safeguards your products from arrival to the end consumer.

Partnering with installation experts is critical for safety and structural integrity, especially for complex systems or rack-supported buildings, where the racking forms part of the building’s structure. At Sky Point Crane, our project management and rigging experience ensures the safe, precise installation of your industrial equipment. We guide you through designing, specifying, and installing the perfect cold storage pallet racking system.

Don’t let the cold chain break your budget or compromise your products. Let’s get started on finding your ideal cold storage pallet racking system today. We invite you to Contact us to discuss your industrial storage project needs and ensure your freezer-friendly racks are truly fit for purpose, built to last, and designed for efficiency.