Why Industrial Heavy Lifting Requires More Than Raw Power

Industrial heavy lifting refers to the specialized handling and installation of indivisible loads typically exceeding 100 tons, requiring individual transport planning and precision engineering rather than standardized approaches. Here’s what defines industrial heavy lifting operations:

- Load characteristics: Weights over 100 tons with dimensions exceeding 100 meters

- Equipment types: Crawler cranes (110-1,600 tonnes), hydraulic gantry systems, strand jacks, and specialized rigging

- Common applications: Generators, turbines, reactors, boilers, transformers, and process equipment

- Transport modes: Self-propelled modular transporters, heavy lift ships, specialized rail cars, and cargo aircraft

- Safety requirements: Engineered lift plans, certified operators, and comprehensive risk assessment

The days of relying on brute force alone are over. Today’s industrial heavy lifting demands precision engineering, meticulous planning, and advanced technology. As one industry expert puts it: “The most important element of any heavy lifting operation is that it takes place safely, protecting people, the load, equipment, and adjacent structures.”

Modern heavy lifting operations sit on the critical path of industrial projects. Whether you’re installing a 500-ton transformer, relocating manufacturing equipment, or positioning wind turbine components, success depends on combining the right equipment with expert planning and flawless execution.

The stakes are high – these operations often determine project timelines and budgets. A single mistake can cost millions in delays, equipment damage, or worse, human injury. That’s why smart project managers focus on precision over power, planning over improvisation.

I’m Dave Brocious, and with over 30 years of experience in strategy and operations across energy and industrial sectors, I’ve seen how proper industrial heavy lifting techniques can make or break major projects. At Sky Point Crane, we’ve built our reputation on solving complex lifting challenges through precision engineering and comprehensive safety protocols.

The Foundation: Meticulous Planning and Engineering

Here’s the truth about industrial heavy lifting: the real work happens long before the first crane arrives on site. While it might look like it’s all about massive equipment and raw power, the foundation of every successful lift is actually built in conference rooms, engineering offices, and computer screens.

Think of it like building a house. You wouldn’t start pouring concrete without blueprints, right? The same principle applies to moving a 300-ton transformer or positioning a massive reactor vessel. The difference is that our “blueprints” need to account for ground bearing pressure, wind loads, and the precise center of gravity of equipment that costs millions of dollars.

Every project begins with comprehensive feasibility studies and detailed site assessments. We’re looking at everything – from whether the ground can handle the weight of our outriggers to identifying overhead power lines that might interfere with our boom path. This isn’t just due diligence; it’s the difference between a smooth operation and a costly disaster.

Our team specializes in Heavy Lift Crane Planning Solutions that cover every detail, no matter how small. We’ve learned that the projects that look effortless are usually the ones with the most thorough planning behind them. That’s why we focus on Managing Crane Projects from Planning to Execution as a seamless process.

The Role of Planning in Industrial Heavy Lifting

When we talk about engineered lift plans for industrial heavy lifting, we’re not talking about rough sketches on napkins. These are detailed engineering documents that specify everything from rigging configurations to crane positioning, load paths, and backup procedures.

Every lift plan starts with precise load calculations and determining the exact center of gravity of what we’re moving. A reactor vessel might weigh 400 tons, but if its center of gravity is off by just a few inches from what we calculated, the entire lift becomes unstable. We also factor in environmental conditions like wind speed limits and weather windows.

Risk assessment is woven throughout this process. We’re constantly asking “what if” questions. What if the wind picks up? What if we encounter unexpected ground conditions? What if there’s an emergency and we need to set the load down quickly?

Our approach to Crane Project Management ensures that all these elements come together smoothly. As one industry expert puts it: “The process of a heavy lift is very well-orchestrated – with all steps and details planned in advance.” That orchestration is what separates successful projects from expensive learning experiences.

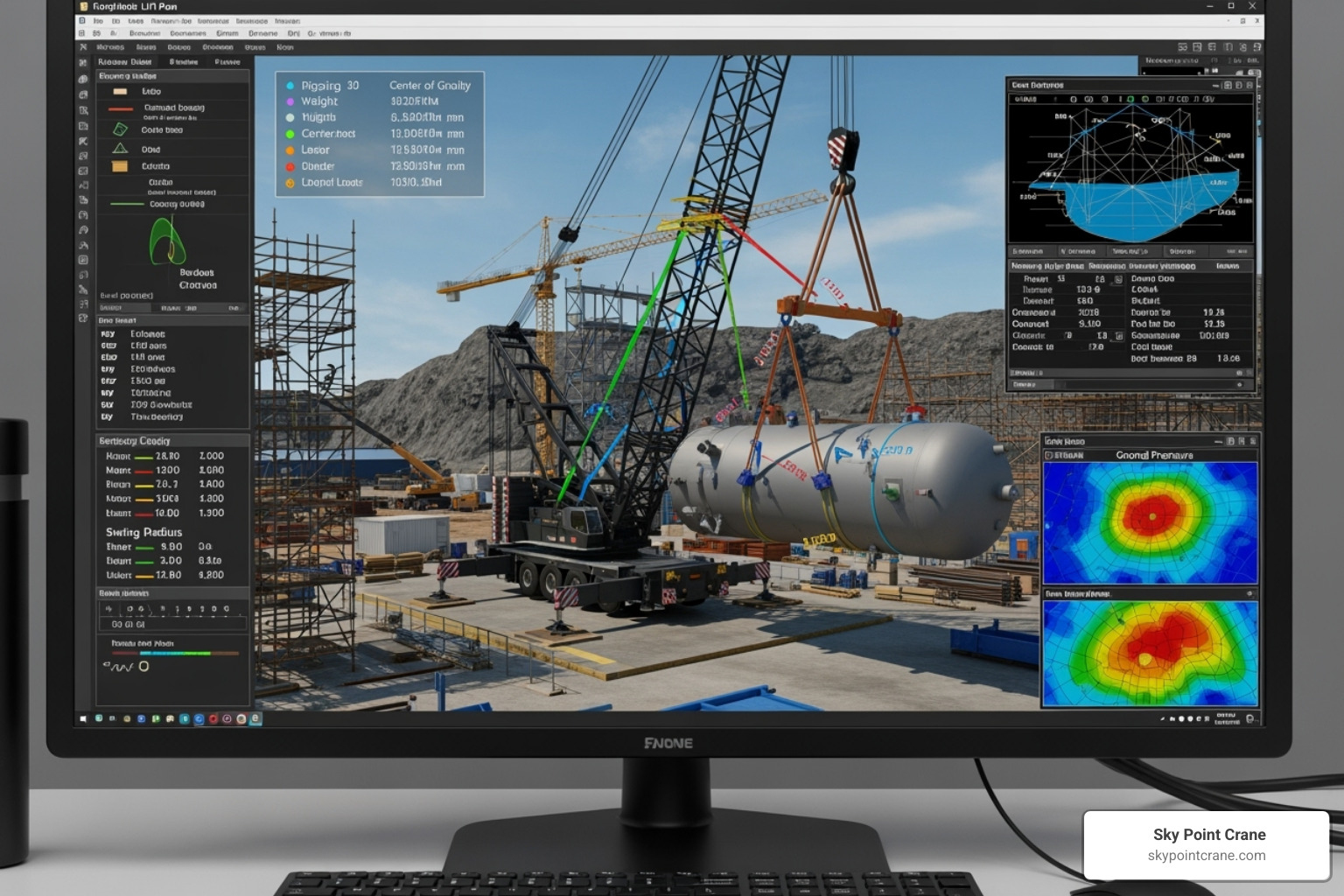

3D Lift Planning: The Future of Precision

Remember when GPS first came out and suddenly you didn’t need to squint at paper maps while driving? That’s what 3D lift planning has done for industrial heavy lifting. We’ve moved from flat drawings to immersive virtual simulations that let us “perform” the entire lift before we ever mobilize equipment.

With 3D modeling, we can spot potential problems that would be invisible on traditional 2D plans. Clash detection shows us exactly where the crane boom might interfere with existing structures. Path optimization helps us find the smoothest, safest route for moving the load. We can even simulate different weather conditions and see how they affect the lift.

The beauty of virtual simulation is that mistakes in the computer cost nothing except time. Mistakes on the job site can cost everything. We can run through dozens of scenarios, test different equipment configurations, and train the crew on the exact procedures they’ll use.

This technology has revolutionized how we approach complex lifts. What used to require educated guesswork now relies on precise engineering analysis. We’re proud to offer comprehensive 3D Lift Planning Services that give our clients confidence before the first piece of equipment rolls through the gate.

The future of crane operations is already here, and 3D Lift Planning: The Future of Crane Operations is leading the way toward safer, more efficient heavy lifting projects.

The Tools of the Trade: Essential Industrial Heavy Lifting Equipment

Think of industrial heavy lifting equipment as the precision instruments of a master craftsman. Just like a surgeon wouldn’t perform delicate work with a butter knife, successful heavy lifting demands the right tool for each specific job.

Modern equipment fleets represent decades of engineering evolution. Today’s machines feature high-pressure hydraulics that respond with surgical precision and advanced control systems that put incredible power at an operator’s fingertips. The days of hoping and praying during a lift are long gone – now we have intelligent systems that monitor every aspect of the operation.

The secret isn’t just having powerful equipment; it’s about matching equipment to the load. A 500-ton transformer requires a completely different approach than a delicate turbine component of the same weight. That’s why our extensive Equipment inventory covers everything from nimble all-terrain cranes to massive hydraulic gantries. We specialize in providing Specialized Lifting Equipment that’s perfectly matched to each project’s unique demands.

Cranes and Advanced Lifting Systems

When you’re dealing with industrial heavy lifting, having the right crane is like having the perfect dance partner – everything just flows better. Crawler cranes are the workhorses of our industry, offering impressive lifting capacities from 110 tonnes all the way up to a jaw-dropping 1,600 tonnes. Their tracked undercarriage provides rock-solid stability on varied terrain, making them ideal for those challenging industrial sites where the ground isn’t exactly level.

All-terrain cranes bring versatility to the table. These mobile powerhouses combine the mobility of a truck with serious lifting capacity – from 25 tonnes to 450 tonnes. They’re perfect for projects where you need to move between multiple lift points or work in tighter spaces.

But sometimes traditional cranes just won’t cut it. That’s where hydraulic gantry systems shine. When you’re dealing with excessive weight, awkward dimensions, or cramped spaces, these systems offer controlled, precise vertical lifting. Our Enerpac Hydraulic Gantry systems can handle up to 1,100 tonnes with the precision of a watchmaker.

Jack-up systems excel at maneuvering and positioning large structural components. With capacities ranging from 56 to 825 tons per unit and lift heights up to 66 feet, they’re perfect for those situations where you need to lift, hold, and precisely position massive components.

For the really heavy stuff, strand jacks are engineering marvels. Using high-pressure hydraulics and a reliable wedge-and-strand system, they offer precision-controlled movements for lifting and lowering massive loads. With capacities from 17 to 1,405 tons, they’re the go-to choice for extremely heavy components.

Don’t forget about skidding systems – the unsung heroes of horizontal movement. These systems can handle 400 tons or more, sliding massive loads across distances with remarkable precision. Our comprehensive Heavy Duty Crane Rental options ensure we have exactly what your project needs.

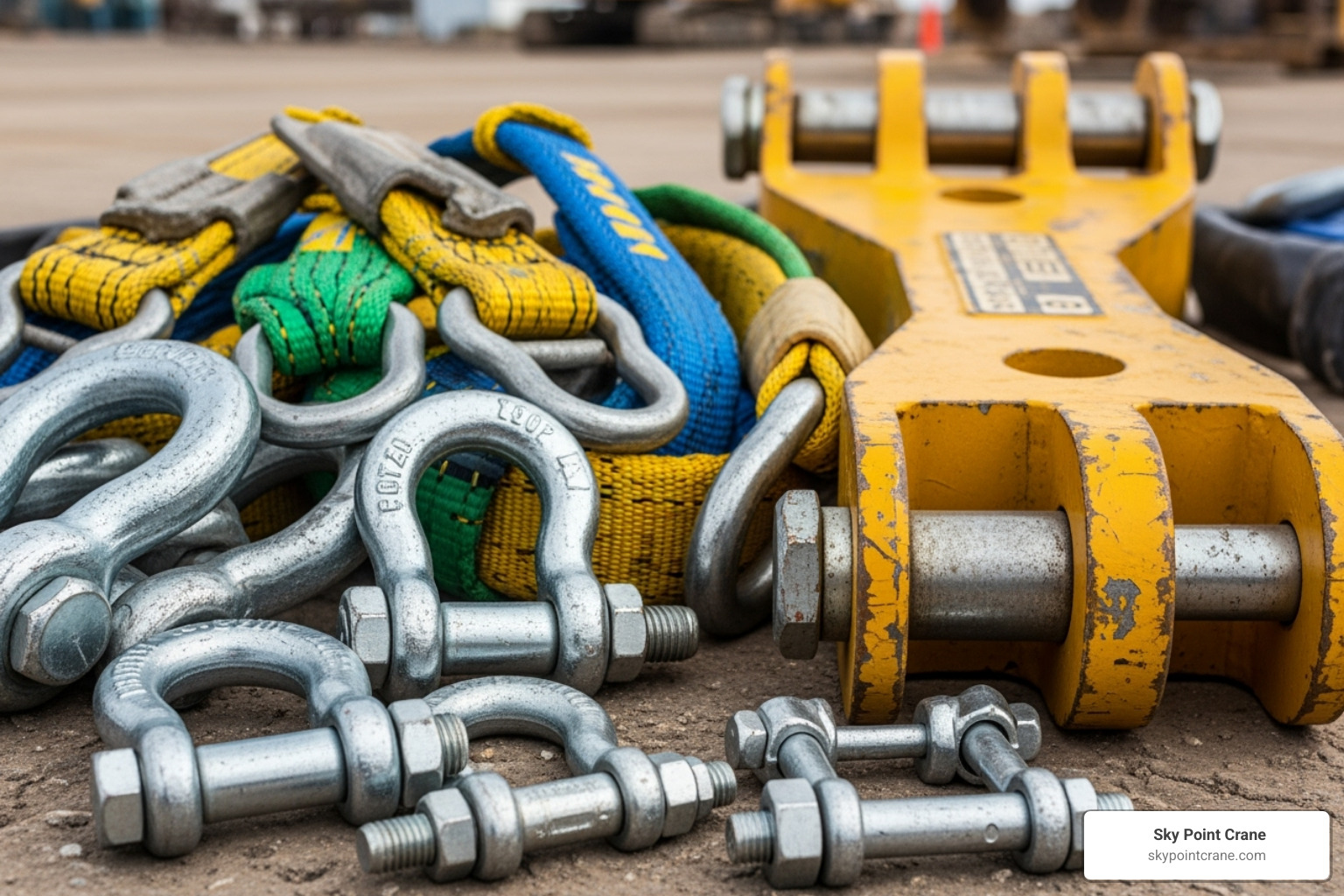

Below-the-Hook: Rigging and Load Monitoring

Here’s where the real artistry happens in industrial heavy lifting. While the crane provides the muscle, the below-the-hook equipment is what connects everything together safely and efficiently.

Spreader beams are the unsung heroes of safe lifting. They distribute loads evenly and prevent damage to delicate or oversized components. Think of them as the protective accept that keeps your valuable equipment safe during the lift.

The right slings make all the difference. Whether we’re using wire rope for heavy-duty applications, synthetic materials for delicate surfaces, or chains for extreme durability, our slings are chosen based on your load’s specific needs.

Shackles might look simple, but they’re the critical connection points that hold everything together. Our high-strength Crosby shackles are built for maximum durability and safety – because the last thing you want is a connection failure during a critical lift.

Modern load monitoring takes the guesswork out of lifting. Technology like our Radiolink plus load cell technology provides real-time force measurements throughout the entire operation. It’s like having a constant conversation with your equipment, ensuring everything stays within safe parameters.

Our comprehensive Rigging Services Pennsylvania ensure that every component is perfectly matched and expertly installed for your specific lift.

Heavy Transport Modes and Machinery

Industrial heavy lifting often starts long before the crane arrives on site. Moving massive components across vast distances requires careful planning and specialized transport equipment.

Self-Propelled Modular Transporters (SPMTs) are engineering marvels that can transport loads up to 4,000 tonnes while offering incredible maneuverability. These computer-controlled platforms can pivot, slide sideways, and steer tight corners that would stop conventional trucks cold.

Road transport using hydraulic modular trailers and powerful tractor units handles the majority of heavy hauls. Every move requires extensive route planning – checking bridge weights, overhead clearances, and tight turns. It’s like solving a massive puzzle where every piece must fit perfectly.

Sea transport becomes the hero for long-distance moves. Heavy lift ships, deck barges, and specialized crane vessels can handle enormous loads cost-effectively. It takes longer than road transport, but when you’re moving a 300-ton generator across the country, patience pays off.

Rail transport offers speed and efficiency for certain routes. Specialized flatcars and Schnabel cars can handle massive loads, though most shipments eventually need to transfer to road transport for final delivery to industrial sites.

Our Full Service Heavy Lift Transport Solutions coordinate every aspect of your project cargo logistics, ensuring seamless movement from origin to final installation.

Executing the Lift: Safety, Personnel, and Primary Challenges

Here’s where the rubber meets the road – or more accurately, where the crane meets the load. The execution phase of any industrial heavy lifting project is that heart-pounding moment when all your careful planning transforms into real-world action. This is where we face the music, dealing with challenges like confined spaces, limited access, and the constant pressure of protecting both our people and your valuable assets.

Think of it like conducting an orchestra. Every instrument needs to play its part perfectly, or the whole symphony falls apart. That means overcoming obstacles that would make other contractors pack up and go home. We’ve built our reputation on solving these complex puzzles, always guided by our unwavering commitment to Crane Safety Standards.

The stakes couldn’t be higher. A single miscalculation doesn’t just mean a bad day at the office – it can mean millions in damages, project delays, or worst of all, someone getting hurt. That’s why we treat every lift like it’s the most important one we’ve ever done.

Paramount Safety Considerations for Industrial Heavy Lifting

Let me be crystal clear about something: safety isn’t just our top priority in industrial heavy lifting – it’s our only priority. Everything else comes second. We’ve seen too many close calls in this industry to take any shortcuts, and frankly, we sleep better at night knowing we’ve done everything possible to protect everyone on site.

Ground stability is where many lifts succeed or fail before they even begin. We’re not just talking about whether the ground looks solid – we need to know exactly how much pressure that soil can handle. When we’re dealing with massive loads, proper DICA outrigger pads become absolutely critical. These aren’t just nice-to-have accessories; they’re the difference between a successful lift and a crane tipping over.

Exclusion zones might sound like fancy terminology, but they’re really just common sense with official boundaries. Nobody – and I mean nobody – gets inside these areas during a lift. We’ve all seen those viral videos of construction accidents, and they usually start with someone being where they shouldn’t be.

Our emergency procedures aren’t gathering dust in some binder. Every person on our crew knows exactly what to do if something goes sideways. Whether it’s sudden weather changes, equipment hiccups, or an unexpected load shift, we’ve got a plan. And more importantly, we’ve practiced it.

Real-time load monitoring gives us eyes and ears on every aspect of the lift. Our computer-based systems don’t just tell us what’s happening – they predict what might happen next. This technology lets us make adjustments before problems become disasters.

Here’s something people don’t always think about: insurance. When you’re lifting equipment worth millions of dollars, you better believe we’ve got coverage for everything – the load, our equipment, and everyone on site. We follow strict Crane Operation Safety Standards because we genuinely care about Understanding the Importance of Crane Safety in Modern Construction.

The Human Element: The Role of Specialized Training

Here’s the thing about industrial heavy lifting – you can have the fanciest equipment money can buy, but if you don’t have the right people operating it, you’re just asking for trouble. Technology is amazing, but it’s the human expertise that makes the real difference between a good lift and a great one.

Our NCCCO Certified Crane Operators aren’t just guys who know which lever to pull. These are professionals who understand the physics, the weather patterns, and the thousand little details that can make or break a lift. We believe deeply in The Importance of Investing in Crane Safety Training for Your Team because every dollar spent on training saves ten dollars in potential problems.

Team communication is where the magic happens. Our certified riggers bring years of expertise in selecting the right gear, inspecting every component, and making sure your load stays exactly where it’s supposed to be. They’re the ones who understand that a slightly off-center load can turn a routine lift into a nightmare scenario.

And let’s talk about our signal persons – these folks are the operator’s eyes and ears when visibility gets tricky. Clear, precise communication isn’t just helpful; it’s absolutely essential. One misunderstood hand signal can mean the difference between success and disaster.

We take The Importance of Certified Riggers in Today’s Construction Industry seriously because we’ve seen what happens when corners get cut. Continuous education and staying current with industry standards isn’t just good business – it’s how we make sure everyone goes home safe at the end of the day.

The bottom line? Our people are what set us apart. We’ve got great equipment, but it’s the expertise and dedication of our team that turns complex challenges into successful projects.

The Payoff: Benefits and Choosing the Right Lifting Partner

When you get industrial heavy lifting right, the rewards go far beyond just moving heavy things from point A to point B. The real payoff comes in maximizing your operational uptime, keeping projects on schedule, and avoiding those costly delays that can derail entire operations. Smart project managers understand that investing in specialized heavy lifting services isn’t an expense – it’s a strategic decision that drives project efficiency and protects their bottom line.

At Sky Point Crane, we’ve seen how proper heavy lifting execution transforms projects. Our Reliable Crane Services are built on decades of experience, and we know that reliability isn’t just about showing up – it’s about delivering consistent results that keep your project moving forward.

Key Benefits of Using Specialized Lifting Services

The difference between hiring specialists versus trying to handle complex lifts with general contractors is like night and day. Here’s what you gain when you partner with experienced industrial heavy lifting professionals:

Risk reduction tops the list of benefits. When you’re dealing with million-dollar equipment and tight project timelines, there’s no room for “learning on the job.” Our certified operators and engineered lift plans eliminate the guesswork, protecting your people, equipment, and project schedule.

Access to expertise means you’re not just renting equipment – you’re buying peace of mind. We’ve solved lifting challenges in cramped spaces, dealt with awkward loads, and steerd complex site conditions. That experience translates directly into smoother operations for your project.

Advanced equipment availability ensures you always have the right tool for the job. Instead of making do with whatever’s available, you get access to our full fleet of specialized cranes, hydraulic gantries, and precision rigging. No more compromising on capability because the right equipment wasn’t available.

Schedule acceleration happens when lifts go according to plan. Our 3D planning and experienced crews help you stay on the critical path, bringing facilities online sooner. When you can lift larger modules in single pieces, you spend less time on integration and more time moving forward.

Cost-effectiveness might seem counterintuitive when you’re looking at specialized service rates, but the math works in your favor. Avoiding delays, preventing equipment damage, and maximizing plant uptime quickly offset the initial investment. The Economics of Crane Rentals makes this clear – it’s about total project cost, not just hourly rates.

Turnkey solutions mean you can focus on what you do best while we handle the heavy lifting. From initial feasibility studies through final demobilization, comprehensive service providers manage the entire process, giving you one point of contact and accountability.

How to Choose Your Heavy Lifting Service Provider

Picking the right partner for your industrial heavy lifting needs isn’t something you want to leave to chance. The decision you make here can determine whether your project finishes on time and on budget, or becomes a cautionary tale about cutting corners.

Experience and history matter more than you might think. Companies that have been around for decades – some family-owned businesses have been operating for over 60 years – have seen it all. They’ve learned from mistakes, refined their processes, and built the kind of institutional knowledge that you can’t get from a textbook.

Fleet size and quality tell you a lot about a provider’s capabilities. Look for companies with diverse fleets that can handle everything from 25-ton all-terrain cranes to 1,600-ton crawlers. But size isn’t everything – maintenance matters just as much. Well-maintained equipment means fewer breakdowns and more predictable project timelines.

Safety record should be your non-negotiable requirement. Ask about their Experience Modification Rate (EMR) and Total Recordable Incident Rate (TRIR). These numbers don’t lie, and they give you insight into how seriously a company takes safety. Our Crane Rental Company Safety Protocols: What to Look For Before Your Next Big Lift guide can help you ask the right questions.

Engineering capabilities separate the professionals from the equipment renters. Look for providers who offer detailed lift plans, feasibility studies, and custom solution design. Companies using 3D lift planning technology show they’re invested in precision and safety, not just moving iron.

Insurance coverage protects everyone involved. Make sure your provider carries comprehensive coverage for equipment damage, load protection, and third-party liability. The last thing you want is finding coverage gaps after something goes wrong.

Client testimonials and references provide real-world validation. Don’t just take marketing materials at face value – ask for references from similar projects and follow up with those clients. Past performance is your best indicator of future results.

As a crane rental and rigging company serving Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, we bring 24/7 availability with NCCCO certified operators to every project. Our comprehensive approach includes 3D lift planning and full project management, ensuring your heavy lifting operations are both safe and efficient. When your project demands precision and reliability, we’re the partner you can count on.

Conclusion

Looking back at everything we’ve covered, it’s clear that industrial heavy lifting has evolved far beyond the days of “throw more muscle at it.” Today’s successful operations rely on the perfect balance of precision over brute force, where intelligent planning meets cutting-edge technology.

The magic happens when three critical elements work together seamlessly: meticulous planning that anticipates every challenge, state-of-the-art equipment that’s perfectly matched to each unique load, and expertly trained personnel who bring years of specialized knowledge to every lift. It’s this synergy that transforms what could be a high-risk operation into a precisely orchestrated success story.

Safety isn’t just important – it’s everything. Throughout our discussion, we’ve seen how rigorous safety protocols, real-time monitoring systems, and continuous training for certified operators create multiple layers of protection. This comprehensive approach ensures that every person goes home safely while protecting valuable equipment and critical project timelines.

The benefits of getting this right are substantial. Projects move faster, facilities come online sooner, and costly downtime becomes a thing of the past. When you partner with specialists who understand the intricate dance of industrial heavy lifting, you’re not just buying equipment rental – you’re investing in expertise that can accelerate your entire project timeline while reducing risks that could otherwise derail your success.

Choosing your lifting partner wisely means looking for a company with a proven safety record, robust engineering capabilities, and the right equipment for your specific challenges. Experience matters, and so does having certified operators who know how to handle the unexpected with calm professionalism.

At the end of the day, achieving your complex project goals efficiently and safely requires more than raw power – it demands precision, careful planning, and an unwavering commitment to doing things right the first time. For comprehensive and safe lifting solutions across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, Sky Point Crane brings the expertise and reliability your project deserves.

Ready to see how we can help with your next challenge? Explore the various markets we serve and find how we can lift your project to new heights.