Why Industrial Racking Installation Sets the Foundation for Warehouse Success

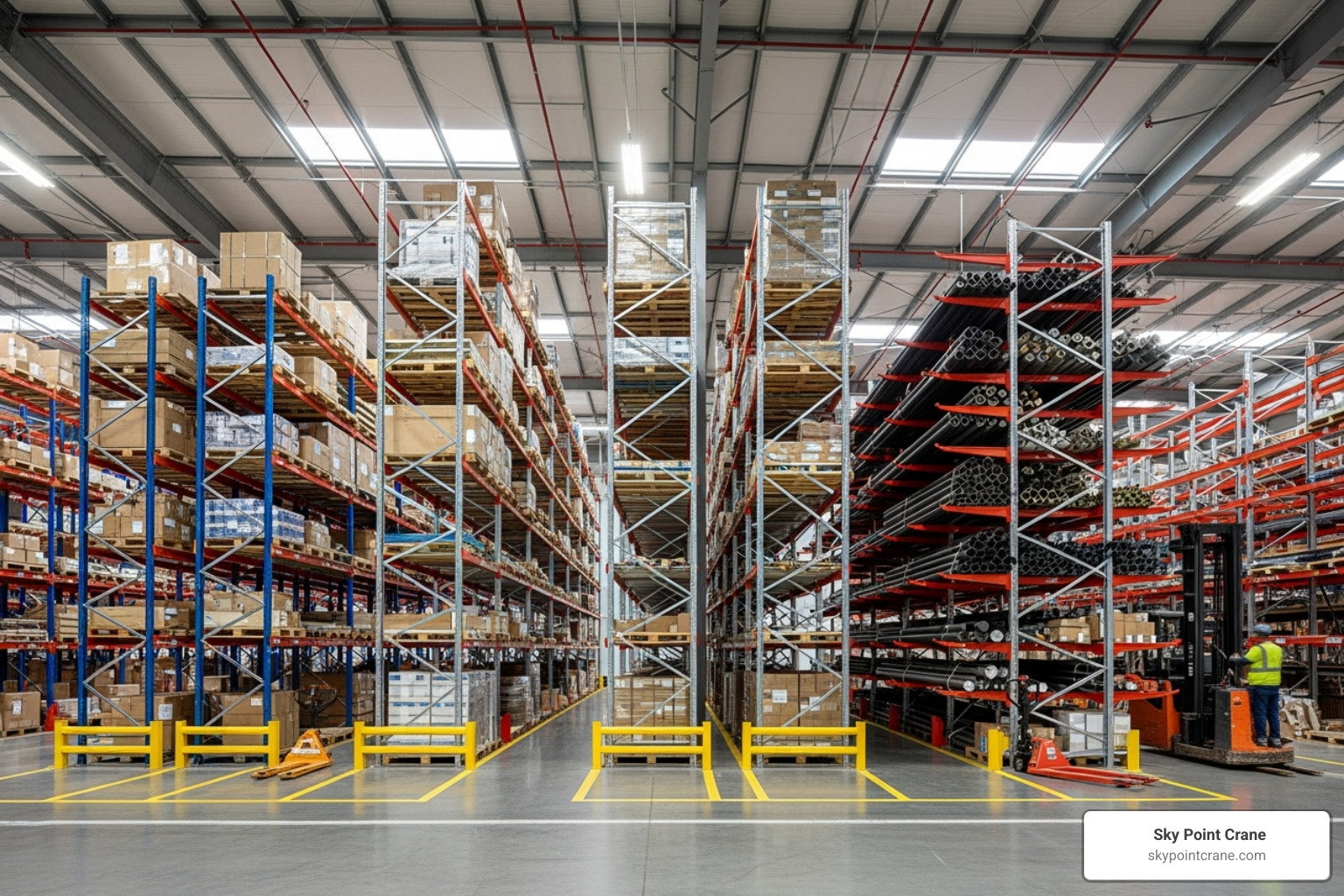

Industrial racking installation is the process of assembling and securing warehouse storage systems to maximize space, ensure safety, and improve operational efficiency. Choosing the right installation team is critical for a stable, code-compliant, and productive warehouse.

Quick Guide to Industrial Racking Installation:

- Pre-Installation Planning – Assess warehouse space, select the right racking type, and evaluate floor conditions.

- Professional Installation Process – Certified installers anchor uprights, install beams, ensure proper bracing, and verify plumb and level specifications.

- Compliance & Safety – Installation must meet RMI/ANSI standards, OSHA guidelines, and local building codes.

- Anchoring Requirements – All pallet rack columns must be secured to the floor with base plates and anchor bolts meeting RMI design standards.

- Post-Installation – Conduct inspections, provide staff training, and establish regular maintenance schedules.

Why it matters: The global industrial racking market is projected to reach USD 17.8 billion by 2030. Properly installed systems can increase warehouse storage capacity by up to 50% while reducing safety hazards. Improper installation, however, can lead to catastrophic failures, worker injuries, and costly disruptions.

Getting your racking installation right involves understanding floor load capacities, seismic design, torque specifications, and other details that define a safe system. As one industry expert noted: “Everything is riding on a safe and timely installation.”

I’m Dave Brocious, and with over 30 years in industrial services, I’ve seen how critical proper Industrial racking installation is. At Sky Point Crane, we apply the same discipline from our lifting and rigging projects to warehouse installations, ensuring every component is correctly placed, anchored, and inspected.

Industrial racking installation terms at a glance:

Pre-Installation Planning: Setting the Foundation for Success

Before bolting uprights to the floor, thorough planning is crucial to prevent costly mistakes. This phase involves understanding your warehouse operations, inventory, and future business needs.

A comprehensive warehouse evaluation examines dimensions and obstructions like support columns, doorways, and HVAC systems. This helps determine the most effective layout to maximize storage while maintaining safe clearances and smooth traffic flow. At Sky Point Crane, we work with detailed installation plans and can verify CAD drawings to ensure your vision aligns with reality and building requirements.

Inventory analysis is also key. The type of products you store—from lightweight boxes to heavy steel coils—dictates the racking system. We analyze product dimensions, pallet weights, and inventory flow to determine if you need first-in, first-out (FIFO) or last-in, first-out (LIFO) access. Your budget shapes the project, but smart planning can reveal ways to phase installation for immediate returns. For more on this, see our guide to industrial storage solutions.

Choosing the Right Racking System

The “right” system depends entirely on your specific requirements.

Selective Pallet Racking is the most common type, offering direct access to every pallet. It’s ideal for operations with many different SKUs requiring quick picking.

Drive-In and Drive-Thru Racking prioritizes density over selectivity. Forklifts drive into the rack structure, storing pallets several deep. This is perfect for large quantities of the same product, like in beverage distribution. Drive-In uses LIFO, while Drive-Thru can support FIFO.

Push Back Racking offers a middle ground. Pallets sit on carts that roll on inclined rails, providing good density (two to six pallets deep) with better selectivity than drive-in systems.

Cantilever Racking uses horizontal arms extending from vertical columns, making it the perfect solution for long, awkward items like lumber, pipes, or furniture.

The selection process considers product dimensions, pallet weight, inventory rotation needs (FIFO/LIFO), and forklift type, as narrow-aisle forklifts can save significant floor space but require compatible racking.

Key Components and Site Assessment

Every racking system relies on fundamental components: upright frames, horizontal beams, wire decking, row spacers, and anchors.

The warehouse floor’s condition is critical for safety and stability. Our site assessments examine several factors:

Floor condition: We check for cracks or uneven surfaces. A standard six-inch thick concrete slab with 3000 psi compressive strength is typical, but a structural engineer should verify your floor can handle the planned loads.

Floor levelness: The Rack Manufacturers Institute (RMI) specifies floors should be flat within 0.5 inches over any 10-foot span. Installing on sloped floors requires special engineering and shimming.

Obstructions: We map all overhead piping, electrical conduits, sprinkler systems, and lighting to ensure the layout is free of conflicts.

For more on creating efficient storage, see our resources on indoor industrial storage. Proper planning saves time, money, and future headaches.

The Professional Industrial Racking Installation Process

When it comes time to actually install your racking system, you’re looking at a process that demands precision, expertise, and an unwavering commitment to safety. At Sky Point Crane, we approach every industrial racking installation with the same level of rigor we bring to our complex crane operations—because frankly, the stability of your storage system is just as critical as safely lifting a 50-ton load.

Professional installation requires certified installers who understand manufacturer specifications and OSHA guidelines. Effective project management is key to coordinating the crew and minimizing disruption to your operations. With our extensive equipment capabilities, we can handle installations of any scale. You can explore what we bring to the table here.

Key Steps in a Professional Industrial Racking Installation

Each step in the installation process builds on the last, ensuring the system’s integrity.

- Layout and chalk lines: We translate the approved plan into precise markings on your warehouse floor, showing where each upright frame will stand.

- Starter bay assembly: The first complete bay is erected to serve as a perfect reference point for the rest of the installation.

- Plumbing and squaring frames: Each upright frame must be perfectly vertical (plumb). We use levels, shims, and diagonal measurements to meet the RMI standard of plumbness within 0.25 inches per 10 feet of height.

- Beam installation and locking: Horizontal beams are attached at specified heights using locking pins or connectors. For T-bolt systems, bolts are torqued to exact specifications (typically 90-110 ft-lbs) to handle rated loads.

- Anchoring uprights to the floor: Each upright is secured to the concrete floor with appropriate anchor bolts and base plates. This step is non-negotiable for stability.

- Final inspection and sign-off: We check every connection, verify safety clips, confirm plumbness, and ensure the system meets all design and safety standards before final sign-off.

The Critical Role of Anchoring and Stability

Anchoring your racking system to the floor is mandatory. According to RMI/ANSI standards for anchoring, all pallet rack columns must be anchored to prevent tipping, especially during loading or accidental impacts.

Floor anchoring requirements depend on the anchor type and your concrete slab’s condition. For example, UNARCO recommends one 1/2-inch diameter anchor bolt per column for standard racks, but your specific application may require different specs.

The height-to-depth ratio is a critical stability calculation. If the ratio exceeds 6:1, the anchors and base plates require special engineering. Ratios over 8:1 often need supplemental stabilization like overhead ties.

Seismic design considerations are also important. In regions with potential seismic activity (ASCE Seismic Design Category B or above), a professional engineer must review the rack design to ensure it can withstand seismic forces.

Shims for leveling are used under base plates to achieve a perfectly level and plumb installation before anchoring, ensuring even load distribution. Bracing and stabilization elements like diagonal braces and row spacers complete the system’s stability. Anchoring is a complex process that requires professional expertise to ensure safety.

Ensuring Safety, Compliance, and Longevity

The work doesn’t stop when the last anchor bolt is tightened. Industrial racking installation is only the beginning of a long-term relationship between you and your storage system. A well-maintained system is a reliable asset; a neglected one is a potential disaster.

At Sky Point Crane, we help you understand how to keep your warehouse safe and compliant. Our commitment to detail is covered on our safety, health, and environment page.

Racking Maintenance and Inspection

Regular inspections are your first line of defense against catastrophic failure. Most problems are easy to spot if you know what to look for. Your inspection routine should focus on:

- Damaged uprights: Dents, bends, or twists in vertical frames can dramatically reduce load capacity.

- Deflected beams: Sagging or bowing indicates overloading or material fatigue.

- Missing safety clips: These small components prevent beams from being accidentally dislodged.

- Loose anchors: Bolts connecting racks to the floor must remain tight and secure.

- Overloading: Ensure load capacity labels are visible on every bay and that weight limits are respected.

We recommend daily visual checks by staff and a comprehensive annual inspection by a trained professional. When damage is found, document it, tag the area “Do Not Use,” and consult an expert for repair or replacement. For more, the Pallet Rack Maintenance guidelines offer excellent advice.

Compliance and Manufacturer Standards

Following standards and regulations protects your people and your business.

RMI specifications are the foundation of safe racking design and installation in North America. Any reputable installation must conform to these guidelines. When selecting components, look for the R-Mark seal, which certifies that the product has been independently tested to meet rigorous structural standards. As RMI notes, not all steel is created equal, and this seal helps you identify quality products.

You must also adhere to local building codes and fire safety regulations, which dictate aisle widths, flue spaces, and clearances. Permits may be required, and a professional installer can help steer this process.

Finally, forklift operator training is crucial. Careless operation is a common cause of rack damage. Ensure every operator understands how to avoid collisions that compromise rack integrity. A well-trained operator is a key part of a safe warehouse environment.

DIY vs. Professional Installation: A Cost-Benefit Analysis

When you’re planning a new industrial racking installation, the question of DIY versus professional installation often arises. While DIY may seem cheaper upfront, the hidden costs and risks tell a different story.

Let’s break down the comparison:

| Factor | DIY Installation | Professional Installation |

|---|---|---|

| Initial Cost | Lower labor costs, but hidden expenses for tool rental, repairs, and delays add up. | Higher upfront labor cost, but includes expertise, efficiency, and insurance. |

| Time to Completion | Significantly longer due to learning curves and lack of specialized equipment. | Much shorter with experienced crews and efficient workflows. |

| Safety & Liability | High risk of injuries, collapses, code violations, and insurance issues. | Lower risk with certified crews, full insurance, and proper safety protocols. |

| Expertise | Limited to instruction manuals and trial-and-error. | Extensive knowledge of rack types, building codes, and problem-solving. |

| Equipment Required | Requires renting or buying forklifts, torque wrenches, and safety gear. | All specialized equipment is provided by the installer. |

| Structural Integrity | Uncertain due to risk of improper assembly, anchoring, or leveling. | Assured through precise, RMI-compliant installation. |

| Compliance & Permits | Navigating OSHA, RMI, and local codes alone is challenging and risky. | Handled by installers who know the regulations and permit process. |

The hidden costs of DIY—from project delays to fixing mistakes—can quickly erase any initial savings. A failed inspection or a collapse can have devastating financial and legal consequences.

Why Professional Industrial Racking Installation is a Non-Negotiable

For a structure designed to hold thousands of pounds, professional industrial racking installation is essential, not a luxury. Professionals provide:

- Specialized Tools and Equipment: Calibrated torque wrenches, laser levels, and proper material handling equipment ensure a precise and safe installation.

- Knowledge of Codes and Regulations: Experts live and breathe OSHA, RMI, and local building codes, ensuring your installation is compliant and avoiding costly fines or shutdowns.

- Liability and Insurance: Certified, insured professionals protect you from liability in case of an accident.

- Efficiency and Speed: Experienced crews complete the job in days, not weeks, minimizing operational downtime.

- Warranty Protection: Many manufacturer warranties are voided by DIY installation, creating a significant financial risk.

- Guaranteed Structural Integrity: Professionals ensure every component is plumb, level, and anchored to RMI standards, creating a system built to last.

As one expert states, with a DIY installation, “You won’t be sure if the process was done correctly… or if OSHA requirements have been met.”

Estimating Installation Costs

Professional industrial racking installation costs typically range from $10 to $30 per square foot for materials and installation combined.

Factors influencing the final cost include:

- Rack type: Selective racking is the most affordable, while more complex systems like drive-in or push-back cost more.

- System complexity: Multi-level systems or integrated mezzanines increase labor costs.

- Height: Taller systems require more time and specialized equipment.

- Location: Labor and material rates vary by region.

- Site conditions: Uneven floors or the need to work around active operations can increase costs.

To get an accurate estimate, always request a formal, site-specific quote from a qualified installer. This is the only way to budget confidently and avoid surprises.

Conclusion

Your warehouse storage system is a strategic investment in your business’s safety, efficiency, and long-term success. A professional industrial racking installation is critical, as every detail—from floor assessment to anchoring and maintenance—matters.

Proper installation can increase your warehouse storage capacity by up to 50% while dramatically reducing safety hazards. It allows your team to work more efficiently and keeps your products secure. Conversely, cutting corners with a DIY approach can lead to catastrophic failures, costly downtime, and serious injuries.

Adherence to RMI and OSHA standards is the foundation of a reliable system. Professional expertise in structural integrity, anchoring techniques, and compliance is what separates a stable, productive warehouse from a dangerous liability.

For complex installations requiring expert rigging and heavy equipment, the right partner is essential. At Sky Point Crane, we approach industrial racking installation with the same precision and safety discipline we bring to our crane operations. Our experienced teams, NCCCO certified operators, and state-of-the-art equipment are ready to tackle your industrial storage projects across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. We ensure every component is perfectly placed, anchored, and inspected.

Your warehouse is the backbone of your operations. Don’t leave its foundation to chance. Contact us for your industrial storage project needs today, and let’s build a safer, more efficient future for your business.