The Best of Both Worlds: Power Meets Mobility

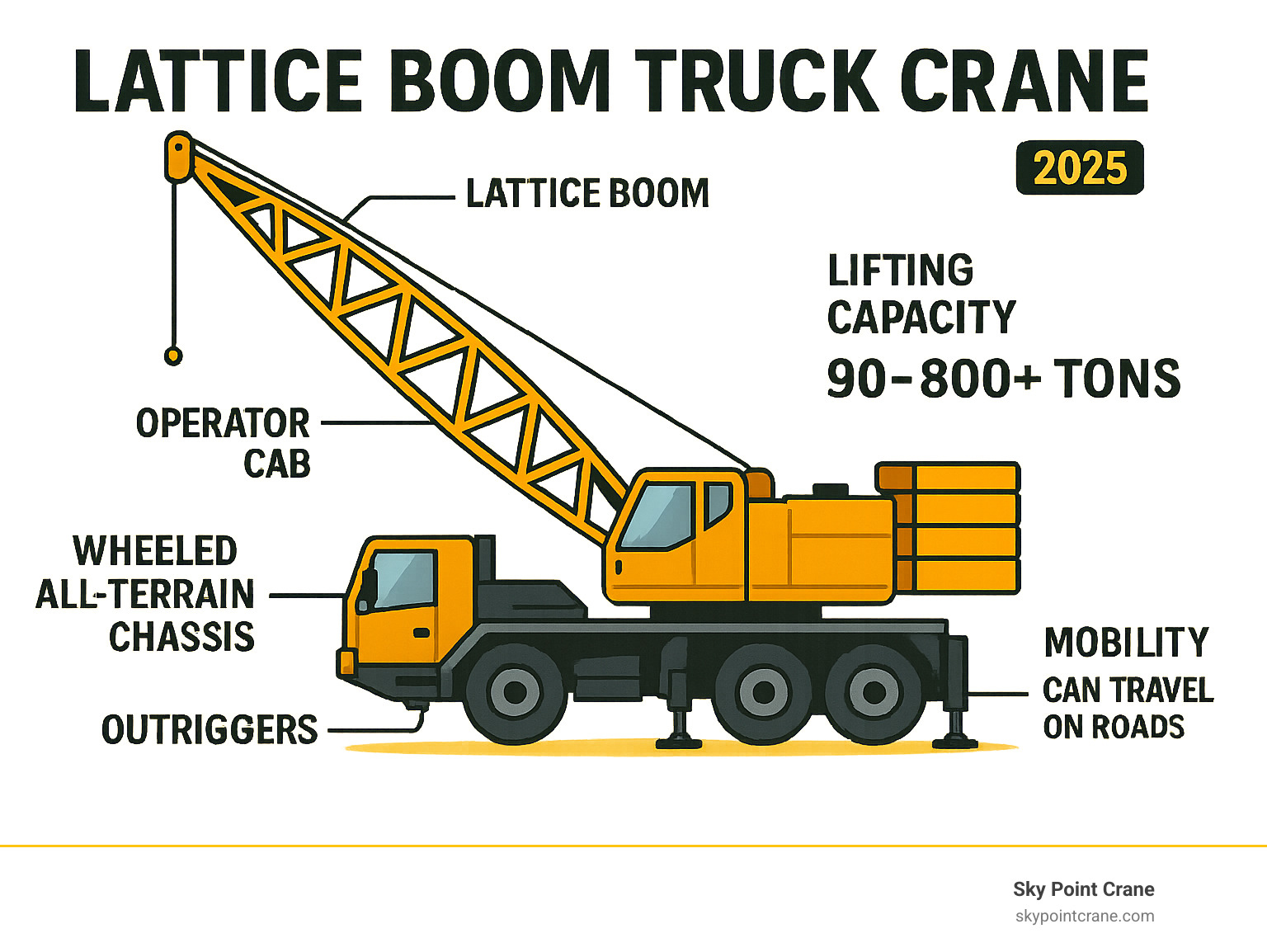

A lattice boom truck crane combines the heavy-lifting strength of crawler cranes with the road mobility of truck-mounted equipment. These hybrid machines offer construction teams a powerful solution for projects requiring both substantial lifting capacity and the ability to move efficiently between job sites.

Key Features of Lattice Boom Truck Cranes:

- Lifting Capacity: 90 to 800+ tons depending on model

- Boom Length: Up to 479 feet with extensions

- Mobility: Can travel on roads between job sites

- Setup: Faster than crawler cranes, uses outriggers for stability

- Applications: Wind energy, bridge construction, industrial projects

The lattice boom design uses a distinctive W or V-shaped steel pattern that maximizes strength while minimizing weight. This allows the crane to handle massive loads – the Liebherr LG 1800-1.0 can lift 800 tons at a 9-meter radius. Unlike crawler cranes that must be disassembled for transport, lattice boom truck cranes can drive directly to job sites on their wheeled chassis.

These cranes represent an economic alternative to telescopic boom cranes for jobs lasting more than a few days. They distribute loads through outriggers rather than tracks, making them ideal for projects requiring both heavy lifting capacity and site-to-site mobility.

I’m Dave Brocious, and with over 30 years of experience in the heavy equipment industry, I’ve seen how lattice boom truck crane technology has evolved to meet the demanding needs of modern construction projects. At Sky Point Crane, we’ve helped countless clients leverage these versatile machines to complete complex lifts safely and efficiently across Pennsylvania, Ohio, West Virginia, and Maryland.

Simple lattice boom truck crane word guide:

The Anatomy of a Lattice Boom Truck Crane

Understanding what makes a lattice boom truck crane tick helps you appreciate why these machines are so effective for heavy lifting projects. Think of it as getting to know the different parts of a well-designed tool – each component has a specific job that contributes to the crane’s overall performance.

At the foundation of every lattice boom truck crane sits the carrier chassis – essentially a heavy-duty truck built to handle serious weight. This wheeled platform is what gives these cranes their road mobility advantage. Instead of needing special transport trailers like crawler cranes, these machines can drive themselves to your job site.

Above the chassis, you’ll find the superstructure – the rotating upper house that contains the operator’s cab, engine, and boom mounting point. This is where our certified operators work their magic, controlling every movement with precision and care.

Counterweights play a crucial balancing act on the back of the superstructure. These heavy blocks offset the weight of whatever you’re lifting, preventing the crane from tipping forward. We can add or remove counterweight sections based on your specific lift requirements – it’s all about finding the right balance for safety and performance.

The outriggers are perhaps the most important stability feature. These hydraulic legs extend from the chassis and lift the entire crane off its wheels during operation. They spread the crane’s weight over a much larger footprint, creating the solid foundation needed for safe heavy lifting.

Key Features of a Lattice Boom Crane Boom

The boom itself is where the lattice construction really shines. Instead of using a solid steel beam (which would be incredibly heavy), engineers designed these booms with an open W or V-shaped pattern of steel tubing. This clever design delivers an exceptional high strength-to-weight ratio – you get maximum lifting power without the bulk.

What makes these cranes so versatile is their modular boom sections. We can add or remove sections to match your project’s exact reach requirements. Need to lift something 200 feet up? We’ll configure the boom accordingly. Working on a shorter lift? We’ll keep it compact for better capacity and easier handling.

For those extra-long reaches, jib attachments can extend your crane’s capabilities even further. While jibs reduce the overall lifting capacity, they’re perfect for placing lighter loads at extreme heights or distances. Our team carefully calculates these trade-offs to ensure every lift meets your project needs safely.

More info about our specialized lifting equipment

The Undercarriage and Stability System

The wheeled all-terrain chassis is what sets these cranes apart from their crawler cousins. Built tough enough to handle various road conditions, this undercarriage lets the crane travel efficiently between job sites. For projects requiring multiple lift locations, this mobility can save you significant time and transportation costs.

The outrigger function transforms the crane from a mobile unit into a stable lifting platform. When extended, these hydraulic supports create a wide, stable base that’s essential for safe operations. The load distribution through outriggers is different from crawler cranes – instead of spreading weight across long tracks, the load concentrates on four specific points.

This brings up important ground pressure considerations. While outriggers effectively stabilize the crane, they do create concentrated pressure points on the ground. Our experienced teams always evaluate site conditions and prepare proper ground support when needed. We take these details seriously because proper foundation work is critical for safe crane operations.

Truck vs. Crawler: A Comparative Analysis

When you’re planning a major lift, one of the biggest decisions you’ll face is choosing between a lattice boom truck crane and a lattice boom crawler crane. It’s honestly like choosing between a sports car and a tank – both are powerful, but they’re built for completely different situations.

The biggest game-changer is mobility. A lattice boom truck crane can literally drive itself to your job site at highway speeds. No special permits for most routes, no convoy of trucks carrying pieces – just one crane operator driving directly to where you need the work done. This is a huge advantage when you’re working on multiple sites or need to relocate frequently.

Crawler cranes, on the other hand, are basically prisoners of their own power. They need to be taken apart, loaded onto multiple trucks, transported piece by piece, and then reassembled on-site. We’re talking about a process that can take several days just to get the crane ready to work.

This transportation difference directly impacts your setup time. Our lattice boom truck cranes can roll up, extend their outriggers, and be lifting loads within hours. Compare that to a crawler crane that might need two or three days of assembly time before it’s operational. When you’re paying for equipment and crew time, those days add up quickly.

Once they’re working, each crane type has its own personality. A lattice boom truck crane becomes a fixed powerhouse once its outriggers are down – it’s not going anywhere until the job is done. Crawler cranes have this cool ability to actually walk around the job site while carrying loads, thanks to their wide tracks. They’re also much more forgiving on soft or uneven ground because they spread their weight over a larger area.

Here’s how they stack up on the key factors that matter most:

| Feature | Lattice Boom Truck Crane | Lattice Boom Crawler Crane |

|---|---|---|

| Mobility | High (road legal, travels between sites easily) | Low (disassembled for transport, slow on-site movement) |

| Setup Time | Faster (hours, minimal assembly) | Slower (days, extensive assembly) |

| Capacity (Typical) | Up to 800 tons (e.g., Liebherr LG 1800-1.0) | Up to 2,500+ tons (some specialized models) |

| Reach (Typical) | Hoist height up to 204 meters (e.g., Liebherr LG 1800-1.0) | Boom length up to 492 feet, jib up to 371 feet (some models) |

| Ground Pressure | Higher (concentrated on outrigger pads) | Lower (distributed over wide tracks) |

| Terrain | Requires firm, level ground for outriggers | Better suited for soft, uneven, or rough terrain |

| On-Site Movement | Fixed once outriggers deployed | Can “pick and carry” loads over short distances |

| Ideal Project | Multiple sites, short-term lifts, urban areas | Long-term projects, heavy lifts, challenging terrain |

The truth is, both cranes are incredible machines – they just shine in different situations. Lattice boom truck cranes are your go-to choice when you need flexibility, speed, and the ability to move between job sites efficiently. Crawler cranes dominate when you’re dealing with massive, long-term projects where maximum lifting capacity and rough terrain performance matter most.

At Sky Point Crane, we’ve worked with both types extensively across Pennsylvania, Ohio, West Virginia, and Maryland. Our experience helps us guide you toward the crane that will make your project run smoothly and cost-effectively.

Operations, Applications, and Safety

The versatility of a lattice boom truck crane makes it an invaluable asset across a wide range of industries and projects.

When I think about where lattice boom truck cranes truly shine, it’s in those projects that demand both serious lifting power and the flexibility to move around. These machines are perfect for large-scale infrastructure development projects like bridge construction, where massive steel beams need to be precisely positioned. I’ve seen our teams use these cranes to lift everything from complex glass roof sections on cruise ships to massive tunnel drilling machines for urban infrastructure projects.

The wind energy sector has become one of our biggest areas of operation. The impressive reach and lifting capacity of modern lattice boom truck cranes make them ideal for erecting those towering wind turbines you see dotting the landscape. Some of the newer models can reach hub heights up to 166 meters – that’s taller than most skyscrapers!

What really sets these cranes apart is their ability to handle projects requiring frequent relocation between lift sites. We regularly use them for telecom tower installations, where mobility between sites is crucial. Crane use in the telecom industry Our steel erection projects also benefit greatly from the combination of power and mobility these cranes provide. Crane rental for steel erection

Transporting a Lattice Boom Truck Crane

One of the biggest advantages of a lattice boom truck crane is that it can actually drive itself to many job sites. But don’t think it’s as simple as hopping in your pickup truck and hitting the road – there are still plenty of logistics and challenges to consider.

For shorter distances or moves between nearby sites, these cranes can travel under their own power. However, longer hauls often require some planning around axle load limits and road regulations. Sometimes we need to remove outriggers or other components to meet weight restrictions for public roads. It’s nowhere near as complex as disassembling a crawler crane, but proper planning is still essential.

The beauty is that even with some disassembly requirements, we’re talking hours instead of days. At Sky Point Crane, we handle all the transport logistics so you don’t have to worry about permits, routing, or compliance issues. Full service heavy lift transport solutions

Essential Safety and Planning

Safety isn’t just something we talk about – it’s woven into every single thing we do. Operating a lattice boom truck crane requires meticulous planning and strict adherence to safety protocols. With approximately 42 crane-related fatalities reported annually according to OSHA data, there’s no room for shortcuts.

Operator certification is our starting point. All our operators are NCCCO certified, meaning they’ve undergone rigorous training and testing to meet the highest industry standards. These aren’t just paper credentials – this certification ensures our operators understand both the technical aspects and safety requirements of operating these powerful machines.

Before any lift begins, our team conducts thorough site preparation. We evaluate ground conditions, identify potential obstructions, and ensure adequate space for crane operation and outrigger deployment. The ground needs to handle the concentrated pressure from those outriggers, so we never skip this critical step.

Every crane has specific load charts that detail maximum lifting capacities at various boom lengths and radii. Our operators treat these charts like gospel – we never exceed the crane’s safe working limits. Understanding moment arm principles is fundamental here. The further a load is from the crane’s center of rotation, the less weight we can safely lift. Our team performs complex calculations considering everything from boom weight to atmospheric conditions.

We use advanced 3D Lift Planning for complex projects, which lets us digitally simulate the entire lift before we even arrive on site. It’s like having a dress rehearsal for your lift, helping us identify potential challenges and optimize the crane’s position for maximum safety and efficiency. 3D Lift Planning: The Future of Crane Operations

Our cranes undergo annual third-party inspections and daily self-inspections to ensure they meet all OSHA safety regulations. We constantly monitor weather conditions, use proper rigging techniques with certified riggers, and maintain detailed documentation throughout every operation. For those interested in the technical details behind these safety calculations, there’s excellent information available about lattice boom crawler crane technical principles that apply to truck-mounted versions as well. Lattice boom crawler crane technical details

With meticulous planning and expert execution, we ensure every lift is handled with the utmost care, minimizing risks and maximizing success for our clients across Pennsylvania, Ohio, West Virginia, and Maryland.

Future Trends and Technological Advancements

The crane industry is experiencing a technological revolution, and lattice boom truck cranes are right at the forefront of these exciting changes. As someone who’s watched this industry evolve for decades, I’m genuinely excited about what’s coming next.

Greener power systems are leading the charge toward a more sustainable future. We’re seeing manufacturers develop hybrid engines that marry traditional diesel power with electric systems. These hybrids don’t just help the environment by cutting emissions – they also run quieter, which is a game-changer when you’re working in busy urban areas where noise complaints can shut down a project faster than you can say “outrigger.”

The integration of AI-assisted lifting technology is perhaps the most fascinating development I’ve witnessed. Modern lattice boom truck cranes are getting smarter by the day, with systems that can analyze load conditions in real-time and provide operators with instant feedback. It’s like having a seasoned crane expert whispering advice in your ear throughout every lift, helping prevent issues before they become problems.

Remote operation capabilities are also changing how we think about crane safety. Imagine being able to control a massive lattice boom truck crane from a safe distance, away from the immediate danger zone. This isn’t science fiction anymore – it’s becoming reality, especially for high-risk environments where keeping operators safe is paramount.

Safety technology continues to advance with improved safety systems that include sophisticated sensors and automated warning systems. These smart systems can detect everything from wind speed changes to ground instability, giving operators crucial information to make split-second decisions.

Modular designs are making cranes more versatile than ever. Future lattice boom truck cranes will feature even more flexible configurations, allowing us to customize them precisely for each job while making transport and setup more efficient. It’s like having a Swiss Army knife that can lift 500 tons – incredibly specialized yet remarkably adaptable.

These innovations aren’t just about building bigger machines. They’re about creating smarter, safer, and more efficient equipment that helps us deliver better results for our clients across Pennsylvania, Ohio, West Virginia, and Maryland.

Frequently Asked Questions about Lattice Boom Truck Cranes

Over the years, I’ve fielded countless questions about lattice boom truck cranes from project managers, contractors, and curious folks who see these impressive machines in action. Here are the answers to the most common questions we hear at Sky Point Crane.

What are the primary advantages of a lattice boom truck crane?

The beauty of a lattice boom truck crane lies in its ability to give you the best of both worlds. You get the robust lifting power you’d expect from a heavy-duty crane – we’re talking capacities up to 800 tons – combined with the road mobility that crawler cranes simply can’t match.

The mobility factor is huge. While a crawler crane needs to be taken apart, shipped in pieces, and reassembled on-site (which can take days), our lattice boom truck cranes can drive right to your job site. This translates to quicker setup times and significant cost savings, especially for projects that don’t need a crane for weeks on end.

Their versatility is another major advantage. Need to reach 479 feet into the air? No problem. Have to move between multiple lift points on the same day? They’ve got you covered. The long reach capabilities make them perfect for everything from setting steel beams to installing wind turbine components.

What types of projects are these cranes best for?

Lattice boom truck cranes really shine on projects where you need serious lifting power but also value efficiency and flexibility. Wind turbine erection is probably their most famous application – these cranes can reach the incredible heights needed to install those massive turbine components, and their mobility means they can move from turbine to turbine across a wind farm.

Bridge construction is another sweet spot. The combination of heavy lifting capacity and precise reach makes them ideal for setting large bridge sections into place. We’ve used them on countless bridge projects across Pennsylvania, Ohio, West Virginia, and Maryland.

Industrial plant maintenance keeps these cranes busy too. When a manufacturing facility needs to replace heavy machinery or install new equipment, the ability to drive the crane right to the plant and set up quickly is invaluable. No one wants their production line down longer than necessary.

The real magic happens on projects requiring frequent relocation between lift sites. If you’ve got multiple buildings going up in a development, or you’re working on infrastructure that spans several locations, a lattice boom truck crane can hop from site to site with minimal downtime. It’s like having a powerful crane that can pack up and move whenever you need it to.

Do lattice boom truck cranes require outriggers?

Absolutely, yes! Outriggers are essential for any lattice boom truck crane operation. Think of them as the crane’s way of planting its feet firmly before attempting a heavy lift.

Here’s why they’re so important: unlike crawler cranes that spread their weight across wide tracks, truck cranes concentrate their weight on wheels. When you’re lifting heavy loads, you need to distribute that load over a wider area to prevent the crane from tipping over. The outriggers do exactly that – they extend out from the chassis and transfer the crane’s weight directly to the ground through large pads.

This is actually a key difference from crawler cranes, which rely on their tracks for stability. When our operators set up a lattice boom truck crane, deploying and properly positioning the outriggers is one of the first and most critical steps. We carefully calculate the ground pressure and ensure the surface can handle the concentrated loads at each outrigger point.

Without outriggers, attempting to lift with a lattice boom truck crane would be like trying to do a handstand on a basketball – not going to end well! The outriggers transform the crane from a mobile machine into a stable lifting platform, ready to handle those impressive loads safely and securely.

Conclusion: Lifting Your Project to Success

After exploring every aspect of these remarkable machines, it’s clear that a lattice boom truck crane truly offers the perfect marriage of raw power and practical mobility. Think of it as having a heavyweight champion boxer who can also run a marathon – that’s the kind of versatility we’re talking about here.

Throughout this guide, we’ve seen how the lattice boom truck crane’s ingenious design combines the immense lifting capacity of traditional lattice boom systems with the game-changing ability to drive directly to your job site. Whether you’re erecting wind turbines that reach toward the clouds or constructing bridges that connect communities, these cranes deliver the versatility and power your project demands.

The beauty lies in their efficiency. Instead of spending days disassembling and reassembling equipment like you would with crawler cranes, a lattice boom truck crane can roll up to your site and be ready for action in hours. That’s not just convenient – it’s money in your pocket and time back in your schedule.

But here’s what really matters: all that power and convenience means nothing without the importance of expert planning and skilled operation. These aren’t machines you can just point and click. They require deep understanding of load charts, ground conditions, weather factors, and safety protocols. One miscalculation, and you’re not just looking at project delays – you’re looking at potential disaster.

That’s exactly why experience matters so much in this business. When you’re dealing with hundreds of tons suspended high in the air, you want operators who’ve seen it all and planners who think three steps ahead. You want teams who treat safety not as a checkbox, but as a sacred responsibility.

For projects across Pennsylvania, Ohio, West Virginia, and Maryland, Sky Point Crane brings together state-of-the-art lattice boom truck cranes with the kind of expertise that only comes from decades in the field. Our NCCCO certified operators don’t just run the equipment – they understand it inside and out. Our meticulous planning process, including advanced 3D Lift Planning, means we’ve already solved tomorrow’s problems today.

Every successful lift starts with the right equipment matched to skilled hands and careful planning. When your project success depends on precision, power, and reliability, we’re here to make it happen safely and efficiently. Ready to get started? Explore our comprehensive crane services and let’s lift your project to success.