Why Professional Machinery Moving Services Matter for Your Project

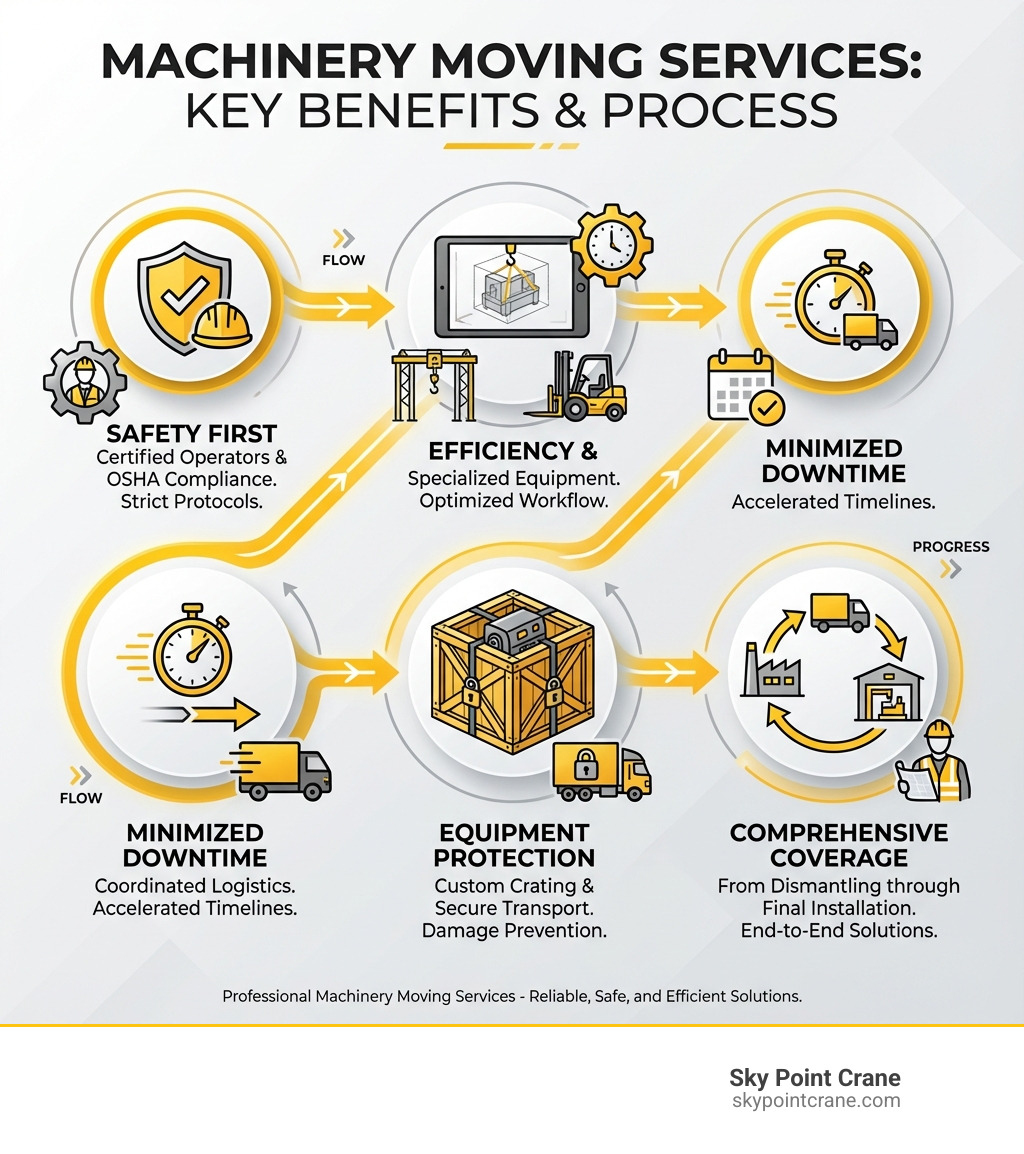

Machinery moving services are specialized industrial relocation solutions for the safe transport, rigging, and installation of heavy equipment. Professional machinery movers provide:

- Comprehensive Planning – Site surveys, 3D lift planning, route analysis, and permitting

- Specialized Equipment – Heavy-duty forklifts (up to 150,000 lbs), gantry systems (up to 1,178 tons), cranes, and hydraulic rigging tools

- Expert Execution – Certified riggers and operators for dismantling, transport, and reinstallation

- Safety and Insurance – OSHA compliance, certified operators, and full liability coverage

- Additional Services – Custom crating, warehousing, and international shipping coordination

Moving a factory isn’t like moving a house. When you’re relocating a 50-ton CNC machine through a narrow doorway or positioning a medical imaging system in a hospital’s basement, the stakes are exponentially higher. A single miscalculation can mean hundreds of thousands in equipment damage, worker injuries, or weeks of production downtime.

Industrial machinery relocation requires surgical precision combined with brute strength. The equipment involved—from pharmaceutical clean room systems to power generation turbines—often represents millions in capital investment. These assets can’t tolerate amateur handling or improvised solutions.

That’s why specialized machinery moving companies exist. With decades of experience, fleets of purpose-built equipment, and teams of certified riggers, these professionals turn what could be a logistical nightmare into a carefully choreographed operation.

The difference between a successful move and a disaster often comes down to expertise. Professional movers bring more than just muscle—they bring engineering analysis, liability protection, and the kind of problem-solving that only comes from moving thousands of machines across every conceivable challenge.

I’m Dave Brocious, and I’ve spent over 30 years helping construction managers and industrial facilities steer complex projects requiring precision lifting and transport. At Sky Point Crane, we’ve built our reputation on solving the toughest machinery moving services challenges across Western Pennsylvania, from natural gas infrastructure to data center installations.

Machinery moving services word roundup:

- Advanced rigging techniques

- Rough terrain crane

- Pittsburgh rigging company

The Anatomy of a Mover: Core Services and Capabilities

Machinery moving services are far more than just transportation; they are a full spectrum of specialized solutions to get your equipment to its new home safely and ready for operation. At Sky Point Crane, we offer comprehensive solutions covering every aspect of your machinery relocation needs.

Core Machinery Moving Services Offered

Our core services are built on precision and expertise, handling everything from a single machine to an entire plant relocation with minimal disruption.

- Heavy Equipment Moving: We specialize in transporting machinery of all sizes, from a few hundred pounds to over a thousand tons, including massive turbines and delicate MRI machines.

- Rigging and Hoisting: More than just lifting, rigging is the art of using hoists, pulleys, and specialized plans to maneuver heavy, awkward, or oversized loads with surgical accuracy. Our Rigging Services Pennsylvania cover lifting, moving, positioning, and securing heavy equipment.

- Dismantling and Reassembly: For machines too large to move in one piece, our skilled teams provide turnkey service. We carefully dismantle, document, transport, reassemble, and calibrate complex machinery to save you time and minimize risk.

- Millwright Services: We go beyond moving to ensure your machinery is properly installed, aligned, and production-ready. Our services include working with conveyor systems, process piping, and providing fabrication and welding to integrate equipment seamlessly.

- Plant and Factory Relocation: We manage the monumental task of relocating entire facilities, from machine shops to production lines. Our comprehensive solutions cover every detail from planning to final setup to get you operational again quickly.

Industries Served and Machinery Types Handled

Our expertise spans a diverse range of industries, each with unique challenges.

- Manufacturing: We move a wide array of equipment, including CNC machines, punch presses, injection molding machines, and food processing lines.

- Energy: We handle heavy lifts and precise placements for power generation turbines, generators, and specialized equipment for the Crane and Rigging in the Natural Gas Industry.

- Healthcare: We provide white-glove treatment for sensitive medical equipment like MRIs, CT scanners, and laboratory apparatus, ensuring precise installation.

- Data Centers: We specialize in moving and installing mission-critical server racks and cooling units, leveraging our experience in Building Data Centers.

- Aerospace: We handle specialized aerospace equipment and components, adhering to the strictest precision and safety protocols.

- Other Industries: Our capabilities also cover pulp and chemical plants, print shops, automotive facilities, and public works, handling equipment like large tanks, silos, and overhead cranes.

Comprehensive Support: From Crating to Storage

We offer a suite of supplementary services to provide a truly end-to-end solution.

- Custom Crating and Packaging: We design and build custom crating for oversized or fragile machinery, including vapor-sealing and airfreight preparation, using heat-treated wood for international shipping compliance.

- Warehousing: We offer secure Indoor Industrial Storage, including climate-controlled options, to help coordinate complex project timelines.

- Logistics Management: Our experts handle all the details, including route planning, acquiring permits for oversized loads, and coordinating escort vehicles for a smooth journey.

- International Shipping Coordination: We coordinate the domestic leg of international shipments within our service area, preparing machinery for sea or air freight, containerizing it, and ensuring regulatory compliance.

The Blueprint for Success: A Guide to Professional Machinery Moving Services

Every successful machinery moving services project begins with a carefully crafted plan. Thorough planning and an unwavering commitment to safety are the cornerstones of our operations.

The Critical Role of Planning and Logistics

At Sky Point Crane, our process is highly collaborative and begins long before any equipment is moved.

- Initial Site Visit and Consultation: Our process begins with an on-site consultation to evaluate the machinery, layout, access points, and your operational needs. This allows us to create a detailed, custom proposal.

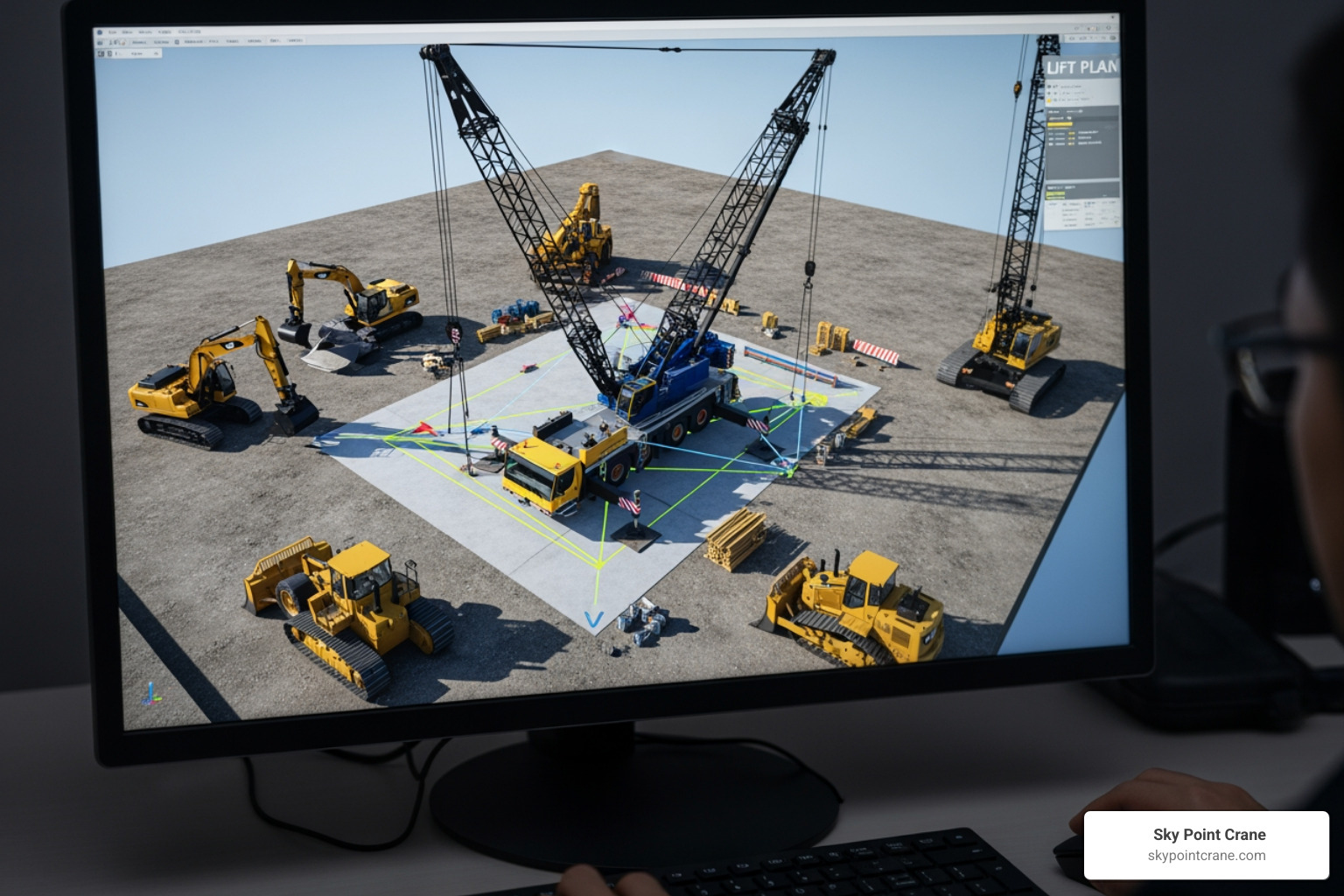

- 3D Lift Planning: For complex lifts, we use 3D lift planning to simulate the entire operation. This technology helps us identify hazards, optimize equipment placement, and map the safest, most efficient path for your machinery.

- Route Surveys and Permitting: We conduct detailed route surveys to identify obstructions and handle all necessary permitting for oversized loads, ensuring full compliance within our service area (PA, OH, WV, and MD).

- Downtime Minimization Strategies: We know downtime costs money. We work with your team to create a logistical plan with precise scheduling, often including off-hours work, to minimize operational disruptions.

- Managing Crane Projects from Planning to Execution: Our project management ensures seamless coordination from the initial consultation to the final installation.

Executing the Move: From Takedown to Transport

Once the plan is in place, our certified teams execute each step with precision and care.

- Safe Dismantling: Our experienced crews carefully dismantle and label all components, protecting delicate parts to ensure straightforward reassembly.

- Secure Loading and Fastening: We use expert rigging techniques to safely load your machinery. Each piece is securely fastened and braced to prevent movement or damage during transit.

- Full Service Heavy Lift Transport Solutions: We provide comprehensive transport solutions, coordinating all aspects of the journey within our service areas.

- Handling Oversized and Complex Loads: We specialize in transporting oversized and complex loads, using specialized trailers and expert drivers to steer challenging routes.

- Offloading and Final Placement: Upon arrival, our team precisely offloads and positions your machinery, navigating tight spaces and making fine adjustments for perfect alignment.

- Reassembly and Leveling: The final step is to reassemble, connect utilities, and ensure your machinery is perfectly leveled and calibrated for immediate use.

Safety and Security: The Non-Negotiable Priority

Safety is embedded in every fiber of our operations. We mitigate risks through rigorous training, strict protocols, and state-of-the-art equipment.

- Adherence to OSHA Standards: We strictly adhere to all OSHA standards. Our riggers, operators, and many drivers are OSHA-certified to ensure a safe work environment.

- Crane Operation Safety Standards: We follow the highest industry standards for crane operations, from daily inspections to proper lift execution.

- Certified Operators and Riggers: Our team is highly skilled and certified. All crane operators are NCCCO certified, and we emphasize The Importance of Certified Riggers in Today’s Construction Industry for safe, efficient operations.

- Insurance and Liability Coverage: We are fully licensed and insured, carrying comprehensive general liability, cargo, riggers liability, and workers’ compensation. We encourage clients to request a Certificate of Insurance (COI) to verify coverage.

- Equipment Inspection Protocols: Our entire fleet undergoes rigorous, regular inspection and maintenance to ensure optimal performance and safety.

The Mover’s Toolkit: Specialized Equipment and Transport

Successfully executing machinery moving services requires an arsenal of specialized equipment designed to handle incredible weights with pinpoint accuracy.

Heavy Lifting and Precision Placement Gear

Our fleet is purpose-built for the unique demands of industrial moves.

- Specialty Forklifts: We use powerful specialty forklifts (e.g., Versa-Lifts, TriLifters) with capacities up to 75 tons (150,000 lbs). Their design allows for exceptional maneuverability and precision in tight, low-clearance spaces.

- Gantry Systems: For indoor or low-overhead environments, we use gantry lift systems. These modular systems, like the Enerpac Hydraulic Gantry, can lift up to 1,178 tons, providing controlled movement for installing large components.

- Hydraulic Jacks and Skates: We use hydraulic jacks (over 100-ton capacity) and machinery skates (up to 100,000 lbs capacity) for precise lifting and smooth horizontal movement across flat surfaces.

- Cranes: Cranes are central to our operations. We deploy a range of mobile, spider, and carry deck cranes from our Specialized Lifting Equipment fleet to match project demands.

- Cantilever Bars: These accessories extend a crane’s reach and improve stability, which is crucial for accessing difficult spots or balancing uneven loads.

Transportation for Every Load

Our transportation solutions are as specialized as our lifting equipment.

- Air-Ride Trailers: We use air-ride trailers for sensitive machinery. They absorb road shocks, reducing vibration to protect your assets during transit.

- Lowboys and Step Decks: Essential for oversized and heavy loads, these trailers have a lower deck height to clear obstacles and a robust construction to handle immense weights.

- Boom Truck Crane: These versatile vehicles combine a crane and truck, ideal for jobs requiring both lifting and hauling in limited space.

- Flatbeds: For standard-sized heavy equipment, flatbed trailers provide a reliable and efficient transport option.

- Satellite-Tracked Fleets: All our transport vehicles are equipped with satellite tracking, allowing us to monitor your shipment’s progress in real-time for added security and transparency.

- Escort Vehicles for Oversized Loads: For over-dimensional loads, we coordinate professional escort vehicles and pilot car services to ensure safe passage.

Making the Right Choice: Vetting Your Moving Partner

Choosing the right machinery moving services provider is a critical decision that can mean the difference between a seamless transition and a costly headache.

Professional Movers vs. The Risks of DIY

The temptation to save money with a DIY move is a false economy, as the risks far outweigh any potential savings.

| Feature | Professional Movers | DIY Attempt |

|---|---|---|

| Expertise | Decades of specialized experience, certified teams | Limited knowledge, often improvised solutions |

| Equipment | Specialized, heavy-duty, purpose-built | Inadequate tools, often rented, not designed for the task |

| Safety | Strict protocols, certified personnel, engineering plans | High risk of injury, property damage, accidents |

| Insurance | Comprehensive cargo, riggers, general liability, WC | None or insufficient personal/business insurance |

| Total Cost | Predictable, efficient, minimizes downtime | Hidden costs of damage, injury, prolonged downtime |

- Hidden Costs of DIY: Consider the costs of equipment or facility damage, prolonged downtime, and legal liability from injuries, which can far exceed any initial savings.

- Potential for Equipment Damage: Improper handling can cause misalignment, structural damage, or complete destruction of precise and expensive industrial machinery.

- Risk of Injury: Without proper training, equipment, and safety protocols, moving heavy objects carries a high risk of serious injury or fatality.

- Lack of Proper Insurance: Standard business policies rarely cover machinery moving risks. A DIY attempt leaves you financially liable for accidents, which can be catastrophic.

Key Considerations When Choosing a Machinery Moving Service

To ensure you partner with a reliable provider, consider these critical factors:

- Experience and Track Record: Look for companies with a long, successful history. We have a solid reputation built over years of service in PA, OH, WV, and MD.

- Certifications (NCCCO, SC&RA): Verify operator certifications like NCCCO and memberships like the Specialized Carriers and Rigging Association (SC&RA), which indicate adherence to high industry standards. Learn more about industry standards.

- Safety Record (EMR, TRIR): Ask for a company’s Experience Modification Rate (EMR) and Total Recordable Incident Rate (TRIR). These safety metrics are crucial performance indicators; lower numbers are better.

- In-House Equipment Fleet: A company that owns and maintains its own specialized fleet offers greater reliability, control, and flexibility than one that relies on rentals.

- Service Area and Capabilities: Ensure the company serves your area. We proudly serve Western and Central Pennsylvania, Ohio, West Virginia, and Maryland with 24/7 crane services.

Understanding Project Costs

The cost of machinery moving services is influenced by several variables:

- Factors Influencing Price: Cost is determined by project complexity, machinery weight and dimensions, travel distance, and labor and permit requirements.

- Weight and Dimensions: Larger and heavier equipment requires more specialized, powerful gear, increasing the cost.

- Distance: Local moves are less expensive than long-distance hauls due to fuel, driver hours, and other travel costs.

- Crane Rental Costs Complete Guide: This resource can provide a deeper understanding of how crane usage factors into project expenses.

- Labor and Permits: The number of skilled personnel and the costs of acquiring necessary permits will also be factored into your quote.

Frequently Asked Questions about Machinery Moving

We understand you have questions, and we’re here to provide clear answers based on our experience in machinery moving services.

How do you move heavy machinery in tight or confined spaces?

This challenge requires a combination of advanced planning and specialized tools.

- Specialized Equipment: We use compact, powerful tools like Spider Cranes, gantry systems, and specialty forklifts (e.g., Versa-Lifts) designed for maneuverability in confined spaces with limited access or overhead clearance.

- Meticulous 3D Lift Planning Services: We use 3D modeling to simulate the entire move, allowing us to identify conflicts and plan the safest path with inch-perfect precision.

- Experienced Riggers: Our skilled riggers use their expertise and precision techniques to guide machinery safely through complex environments and tight passages.

What kind of insurance should a machinery mover have?

A reputable machinery mover must have comprehensive insurance to protect your assets. Key coverages include:

- General Liability: Covers property damage or bodily injury during general business operations.

- Cargo Insurance: Protects your machinery from loss or damage while in transit.

- Riggers Liability: Specialized insurance covering damage to machinery or property during the rigging process.

- Workers’ Compensation: Covers medical expenses and lost wages for the mover’s employees if injured on the job.

- Always ask for a Certificate of Insurance (COI): This document provides proof of current insurance coverage and lists policy limits. Review it to ensure adequate protection.

Can machinery be moved internationally?

While our primary service area is PA, OH, WV, and MD, we can coordinate the domestic portion of international moves. Full-service movers handle the entire process:

- Logistics: A comprehensive mover coordinates customs documentation, tariffs, and import/export regulations.

- Custom Crating: International moves require specialized crating with features like vapor-sealing and containerizing for protection during sea or air freight.

- Regulatory Compliance: Experienced movers steer complex international shipping laws, securing permits and declarations to prevent delays and ensure smooth customs clearance.

Conclusion: Ensuring a Smooth and Successful Relocation

Navigating the complexities of industrial relocation is a monumental task, but with the right partner, it can be a seamless and efficient process. We’ve explored the intricate world of machinery moving services, from the core offerings and specialized equipment to the critical role of planning, safety, and choosing the right provider.

The value of hiring a certified partner cannot be overstated. It brings peace of mind, ensures operational efficiency, and safeguards your significant capital investments. Professional planning and an unwavering commitment to safety are not just buzzwords; they are the cornerstones of a successful move.

At Sky Point Crane, we embody this commitment. With our certified expertise, state-of-the-art equipment, and dedication to precision, we are ready to tackle your toughest machinery moving services challenges across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. Our 24/7 service, coupled with advanced capabilities like 3D Lift Planning, means we’re always prepared to deliver.

Don’t let the daunting task of machinery relocation become a burden. Let us apply our decades of experience and specialized resources to your next project.

Request a Quote today and find how we can help you achieve a smooth and successful relocation. You can also Explore our Crane Rental services for your next project to see the full scope of our capabilities.