Why Telescopic Boom Truck Cranes Are Essential for Modern Construction

Telescopic boom truck cranes are the workhorses of construction sites across Western Pennsylvania and beyond. These versatile machines combine mobility, reach, and lifting power in a single package that can handle everything from steel erection to HVAC installation.

Key Features of Telescopic Boom Truck Cranes:

- Mobility: Drive directly to job sites on standard truck chassis

- Rapid Setup: Deploy outriggers and start lifting in minutes

- Variable Reach: Extend boom sections from 36 feet to over 200 feet

- Lifting Capacity: Handle loads from 5 tons to over 100 tons

- Compact Design: Steer tight spaces other cranes cannot access

These cranes offer best efficiency in transportability compared to traditional mobile cranes. As one industry expert noted, LTF cranes “cover around 15,000 kilometers per year and are more economical than conventional mobile cranes over long distances.”

The telescopic boom design allows operators to adjust reach and height precisely for each lift. Modern models feature advanced safety systems like Load Moment Area Protection (LMAP) and can be equipped with jibs to extend reach even further.

About the Author: I’m Dave Brocious, with over 30 years of experience in the construction and equipment industry, including extensive work with telescopic boom truck crane operations and lift planning. At Sky Point Crane, we’ve helped countless project managers solve complex lifting challenges with the right equipment and certified operators.

Basic telescopic boom truck crane terms:

Anatomy of a Powerhouse: The Core Components

A telescopic boom truck crane is an incredible machine, with every component engineered for perfect harmony. Let’s look at the key parts that transform an ordinary truck into a lifting powerhouse.

The telescopic boom sections are the reason these cranes get their name. These nested steel sections slide smoothly within each other, giving you incredible flexibility in reach and height. Some manufacturers use pentagon and hexagon shapes blended with steel plates to improve bending resistance, ensuring these booms can handle years of heavy lifting while maintaining their precision.

The hydraulic system is the heart of the crane, powering every movement. This pressurized fluid system extends the boom, raises loads, and operates the outriggers. Modern systems generate 14 Kw to 60 Kw of power, with hydraulic flow rates from 25L/min to 120L/min, enabling smooth, precise control.

Outriggers and stabilizers are the crane’s foundation. Before lifting, these hydraulic legs extend from the chassis to create a rock-solid base. Common A-frame or H-style configurations provide optimal stability for different job site conditions. Advanced systems can calculate maximum lifting capacities for specific support configurations, ensuring operator confidence in tight spaces.

The hoist and winch system does the heavy lifting. It consists of a powerful drum that spools the wire rope, driven by a motor generating line pulls from 15,822 lbs to over 23,000 lbs. Modern designs integrate the winch into the boom structure with spring brakes and friction systems for reliable, safe operation.

The operator’s cab is where skill meets technology. Modern cabs are designed for the operator, with extensive glass for maximum visibility, ergonomic controls, and comfortable seating. Some cabs tilt up to 20 degrees for a better view during high lifts. For complex lifts, comfort and visibility are necessities.

Counterweights are crucial for safe operation. These heavy steel blocks are positioned opposite the boom to counterbalance loads and prevent tipping. Advanced models feature hydraulically removable counterweights that can be adjusted in minutes, making transport and setup more efficient.

Finally, the carrier or truck chassis makes these cranes versatile. Unlike specialized carriers, telescopic boom truck cranes use standard truck chassis, allowing them to travel on regular roads without special permits. This makes them economical for projects with frequent moves between job sites.

Together, these components create a mobile, powerful, and precise machine for everything from delicate HVAC installations to heavy steel erection.

Want to see how these components translate into real-world lifting solutions? Check out more info about our equipment to find which crane specifications match your project needs.

The Versatility Advantage: Why Choose a Telescopic Boom Truck Crane?

Telescopic boom truck cranes are like the Swiss Army knife of the lifting world, offering an incredible combination of flexibility, efficiency, and practicality that sets them apart from other crane types.

The mobility factor truly sets them apart. Unlike crawler cranes needing special transport, a telescopic boom truck crane drives itself to the job site. Whether in downtown Pittsburgh or remote West Virginia, they travel on regular roads without issue. These workhorses can cover 15,000 kilometers per year, making them built to move economically.

Rapid setup is another game-changer. Crews can arrive, extend the outriggers, and start lifting within minutes. Compared to the hours needed to assemble other cranes, this quick deployment saves significant time and money, especially when moving between multiple lift points.

Cost-effectiveness extends beyond mobilization. Built on standard truck chassis, their fuel and spare parts are affordable. Maintenance items are mass-produced truck parts, not expensive specialty components. For projects with frequent moves and short lifts, they are hard to beat from a budget perspective.

The compact design is impressive. With the boom fully retracted, the crane can access spaces larger machines cannot. We’ve maneuvered them through narrow city streets, residential areas, and congested industrial sites. This transportability eliminates headaches with special permits or route planning.

The versatility of the telescopic boom is a key advantage. You can precisely adjust reach and lifting capacity for any situation. Some models offer dual-rating capabilities, functioning as both a full-capacity crane and an aerial lift, providing excellent value.

From installing new power lines to maintaining existing infrastructure, these cranes handle it all. You can learn more about their critical role in Crane Use in the Construction of Electrical Transmission Lines.

Common Industries and Applications

The adaptability of telescopic boom truck cranes makes them invaluable across many industries. We’ve deployed these versatile machines in numerous situations.

Construction sites are their natural home. They are the backbone of modern building, setting steel beams, handling precast concrete, and installing rooftop HVAC units. Their ability to quickly reposition on a large project keeps timelines on track.

Steel erection projects benefit from their precision and mobility. The ability to move efficiently from bay to bay while maintaining lifting capacity is key to productivity.

HVAC installation often requires precise positioning on rooftops or in tight spaces. The compact design and maneuverability of these cranes make them ideal for getting heavy equipment exactly where it needs to go.

The telecommunications industry relies on them for tower work, including erecting, maintaining, and upgrading cell towers. We specialize in Crane Rental for Cell Towers, helping keep communities connected.

Utility work keeps these cranes busy setting power poles and maintaining transmission lines, often in remote locations and varied terrain.

The oil and gas sector uses these cranes for assembling drilling equipment, maintaining facilities, and handling heavy components in remote locations, where reliability and precision are critical.

Key Classifications: Stand-Up vs. Swing Seat

When selecting a telescopic boom truck crane, you’ll find two main operator configurations: stand-up and swing seat. The choice depends on your project needs and working conditions.

Stand-up boom trucks position the operator on a platform at the rear or side of the truck. This provides excellent direct visibility of the load, which is invaluable for close-quarters work. These models generally handle lighter capacities and are perfect for quick, repetitive lifts.

Swing seat models feature an enclosed cab on the crane’s superstructure that rotates with the boom. This design offers comprehensive visibility throughout the swing radius, and many cabs tilt up to 20 degrees for better sight lines on high lifts. The enclosed cab also protects operators from the weather.

Capacity ranges differ between the two. Stand-up models typically max out around 33 tons with boom lengths up to 127 feet. Swing seat cranes offer higher capacities, often 30 to 60 tons or more, with boom lengths over 151 feet and tip heights exceeding 200 feet.

Job site suitability also varies. Stand-up models excel where frequent operator movement and quick setups are needed. Swing seat models are better for longer jobs, complex lifts, or harsh weather where operator comfort impacts safety and productivity.

Both configurations deliver the reliability and precision that make telescopic boom truck cranes so valuable. Our team at Sky Point Crane can help you determine if a Stand Up Boom Truck or swing seat model best fits your project for optimal safety and efficiency.

Selecting the Right Crane: Critical Factors for Your Project

Choosing the right telescopic boom truck crane for your project isn’t just about picking the biggest one available – it’s about finding the perfect match for your specific needs. At Sky Point Crane, we’ve learned that every lift tells a story, and understanding that story is what makes the difference between a smooth operation and a costly headache.

Think of it like choosing the right vehicle for a road trip. You wouldn’t take a sports car to haul furniture, and you wouldn’t use a moving truck for a quick grocery run. The same logic applies to crane selection, and that’s where our expertise really shines.

Project scope forms the foundation of our selection process. We need to know exactly what you’re lifting – not just the weight, but the dimensions, fragility, and final destination of your load. A 10-ton steel beam requires a completely different approach than a 10-ton piece of delicate equipment that needs to be placed with surgical precision.

Site conditions can make or break a lift. We carefully evaluate ground stability because even the most powerful crane is useless if it can’t set up safely. Are there overhead power lines? Tight access roads? Limited space for outrigger deployment? These factors directly influence which crane will work best for your situation.

The mobility requirements of your project play a huge role too. If you need a crane that can hop between multiple locations throughout the day, the inherent transportability of telescopic boom truck cranes becomes invaluable. They’re built to move efficiently, which translates to cost savings for you.

Our advanced 3D Lift Planning technology helps us visualize these factors before we ever arrive on site. This planning process ensures we select the crane that will handle your project safely and efficiently, without any surprises.

Ground stability deserves special attention because it affects everything from crane positioning to load capacity. Soft or uneven ground might require additional matting or influence our choice of crane size and setup configuration.

| Project Need | Crane Selection Factors |

|---|---|

| Heavy Lifting (50+ tons) | Higher capacity models with robust hydraulic systems and extended outrigger base |

| High Reach (100+ feet) | Longer boom sections, possible jib attachments, improved tip height capabilities |

| Tight Site Access | Compact chassis, shorter overall length, flexible outrigger configurations |

| Multiple Daily Moves | Standard truck chassis for road travel, quick setup capabilities |

| Precision Placement | Advanced control systems, excellent operator visibility, fine load control |

How Lifting Capacity Influences Your Choice of a Telescopic Boom Truck Crane

When we talk about lifting capacity, we’re diving into the heart of what makes each telescopic boom truck crane unique. It’s not just a single number – it’s a complex relationship between weight, distance, and physics that determines what your crane can safely accomplish.

Load charts are our bible in this process. These detailed tables show exactly how much weight a crane can lift at various boom lengths and distances from the crane’s center. A crane might handle 100 tons when the load is just 7 feet away, but that capacity drops significantly as you extend the boom or increase the radius.

The lift radius – the horizontal distance from the crane’s centerline to the load – has a dramatic impact on capacity. Think of it like a seesaw: the farther out you place the weight, the harder it becomes to lift. This is why we always consider not just what you’re lifting, but exactly where it needs to go.

Gross Vehicle Weight Rating (GVWR) affects how much ballast the crane can carry while traveling on public roads. This influences the crane’s stability and determines what additional counterweights might be needed once we arrive on site.

We always build in a healthy safety margin when selecting crane capacity. The actual load weight is just the starting point – we factor in rigging equipment, potential wind loads, and dynamic forces that occur during lifting. It’s better to have more capacity than you need than to find you’re cutting it too close.

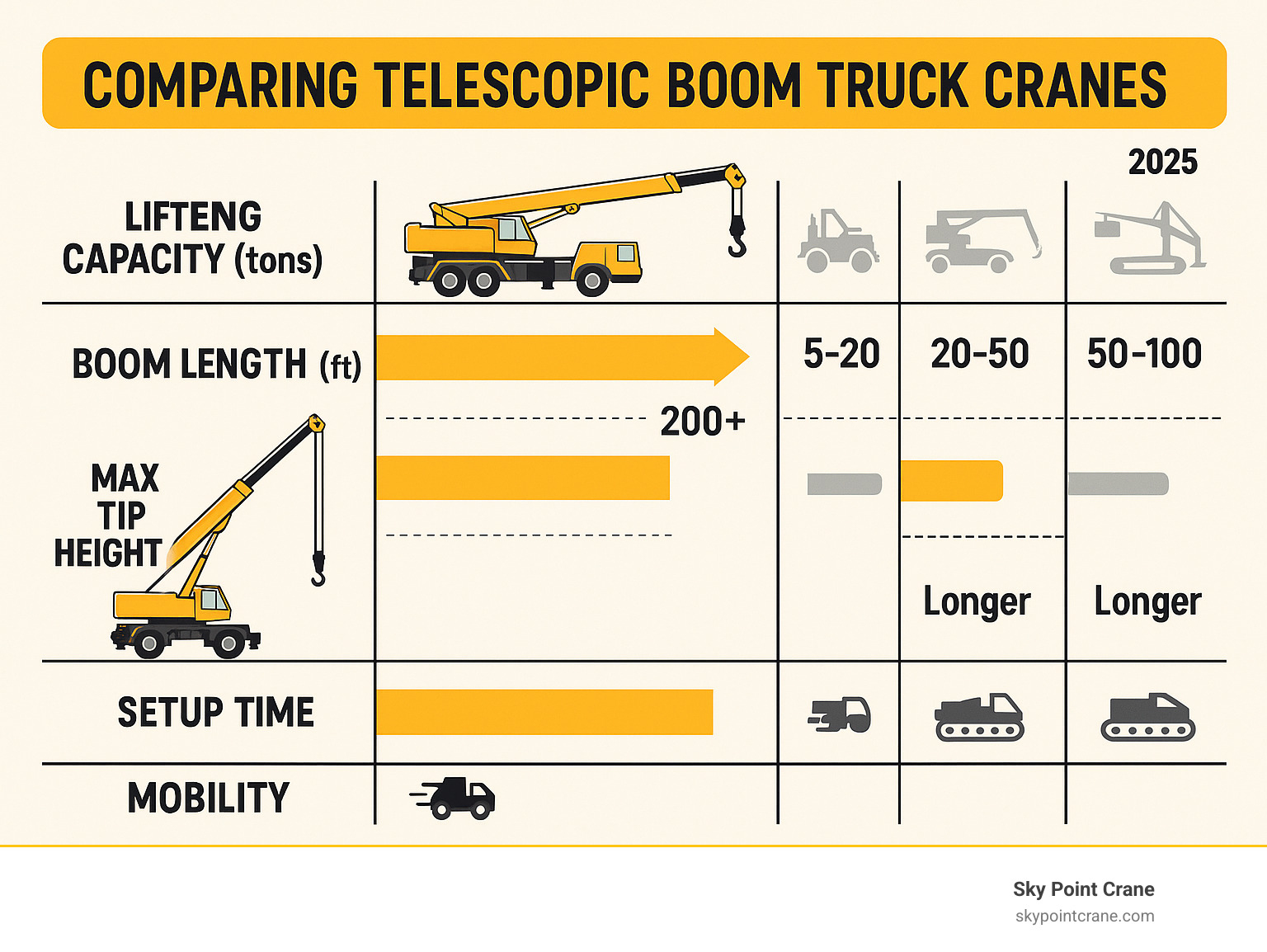

Maximum lifting capacity varies dramatically across different models. Smaller units might handle 5 to 20 tons, perfect for HVAC installations or light steel work. Mid-range cranes typically lift 30 to 60 tons, ideal for most construction applications. The heavy hitters can manage 100 tons or more, tackling the biggest industrial projects.

For specific equipment options that match your lifting requirements, explore our Boom Truck Crane Rental services.

How Boom Length and Reach Impact Your Project

The reach of your telescopic boom truck crane determines not just how high you can go, but how you can steer around obstacles and position loads precisely. It’s often the difference between completing a job efficiently and having to completely redesign your lift plan.

Maximum tip height represents the highest point your crane can reach with its boom fully extended. Modern telescopic boom cranes can reach impressive heights – some extending over 200 feet into the air. This vertical reach is crucial for rooftop installations, high-rise construction, or any project where you need to clear tall obstacles.

Jib attachments can extend your crane’s capabilities even further. These lattice extensions attach to the main boom, providing additional reach both horizontally and vertically. A jib can transform a 140-foot boom into a 200-foot reach machine, opening up possibilities that wouldn’t exist with the main boom alone.

The working envelope defines the entire three-dimensional space where your crane can operate effectively. Understanding this envelope during planning helps us position the crane optimally and ensures we can reach every required lift point without repositioning.

Obstacle clearance becomes critical in congested job sites or urban environments. A longer boom or properly configured jib allows the crane to reach over buildings, trees, or other equipment. This capability can save hours of setup time and eliminate the need for multiple crane positions.

The telescopic design itself provides incredible flexibility. Instead of being locked into a fixed boom length, operators can extend or retract sections as needed throughout the job. This adaptability makes telescopic boom truck cranes particularly valuable for projects with varying lift requirements.

Selecting the right combination of capacity and reach requires experience and careful planning. That’s where our team’s decades of experience and advanced planning tools make all the difference in ensuring your project succeeds.

Operating with Precision: Safety, Technology, and Maintenance

When I watch one of our telescopic boom truck crane operators at work, I’m always impressed by the precision and skill required. These machines are incredibly powerful, but their true strength comes from the combination of expert operation, cutting-edge technology, and meticulous maintenance that keeps them running safely day after day.

At Sky Point Crane, we’ve built our reputation on one simple principle: safety first, always. Every single one of our operators is NCCCO certified, which means they’ve passed rigorous training and testing to prove they can handle these complex machines. But certification is just the starting point – we also conduct daily inspections before every job and follow strict routine maintenance schedules to keep our equipment in peak condition.

The technology in modern telescopic boom truck cranes is honestly amazing. These aren’t your grandfather’s cranes – they’re sophisticated machines with computer-controlled systems that help prevent accidents before they happen. But even with all this technology, the human element remains crucial. That’s why we emphasize comprehensive training and follow industry best practices from organizations like OSHA.

You can learn more about our commitment to safe operations in our detailed guide on Understanding the Importance of Crane Safety in Modern Construction.

Essential Safety Practices for a Telescopic Boom Truck Crane

Safety isn’t just a checklist item for us – it’s woven into everything we do. When you’re dealing with machines that can lift 100 tons and reach heights of over 200 feet, there’s no room for shortcuts or “close enough.”

Our operator certification process goes beyond just getting the NCCCO card. Every operator must demonstrate they understand load charts, can properly set up outriggers, and know how to communicate effectively with ground personnel. We follow strict Crane Operation Safety Standards that have been proven to prevent accidents.

Load Moment Area Protection (LMAP) is one of the most important safety features on modern telescopic boom truck cranes. Think of it as a smart guardian angel that constantly monitors the crane’s capacity and warns the operator if they’re approaching unsafe limits. Combined with Rated Capacity Limiters, these systems can actually prevent the crane from attempting a lift that exceeds its capabilities.

Outrigger setup might seem straightforward, but it’s actually one of the most critical steps in any lift. These stabilizing legs must be properly positioned and extended to create a stable base. We calculate the exact setup needed for each job, considering ground conditions and the specific lift requirements.

The importance of rigging and signal persons cannot be overstated. These are the folks who ensure the load is properly secured and guide the operator when visibility is limited. Clear communication between all team members can mean the difference between a successful lift and a dangerous situation. You can read more about Why Rigging and Signal Persons are Essential in Crane Operations.

Notable Technological Advancements

The evolution of telescopic boom truck crane technology over the past decade has been remarkable. Where operators once relied primarily on experience and intuition, today’s cranes offer advanced control systems that provide real-time feedback and assistance.

Remote operation capabilities are becoming increasingly common, allowing operators to control the crane from outside the cab when they need a better view of the load or work area. This isn’t just convenient – it’s often much safer, especially for complex lifts in tight spaces.

Perhaps the most exciting advancement is 3D lift planning software. This technology lets us create virtual models of your job site and test different lifting scenarios before we even arrive. We can identify potential obstacles, optimize crane positioning, and ensure we bring exactly the right equipment for your project. Our expertise with 3D Lift Planning has helped countless clients avoid delays and safety issues.

Improved operator comfort might not sound like a safety feature, but it absolutely is. When operators are comfortable – with ergonomic controls, climate-controlled cabs, and excellent visibility – they can focus entirely on the job at hand. Some modern cabs even tilt hydraulically to give operators a better view during high lifts, reducing neck strain and improving precision.

Modern technology has also enabled innovations like dual-rating functionality, where a single telescopic boom truck crane can serve as both a crane and an aerial work platform. This versatility means fewer pieces of equipment on your job site and more efficient operations overall.

The integration of The Role of 3D Lift Planning in Successful Construction Projects with these technological advances has transformed how we approach complex lifting challenges, making operations safer and more efficient than ever before.

Conclusion

After exploring the incredible world of telescopic boom truck cranes, it’s clear why these machines have become the go-to choice for construction and industrial projects throughout our region. From the busy streets of Pittsburgh to remote job sites in rural West Virginia, these versatile workhorses deliver the perfect blend of power, mobility, and precision that modern projects demand.

What makes these cranes truly special isn’t just their impressive lifting capabilities or their ability to squeeze into tight spaces. It’s how they combine mobility with muscle – driving directly to your job site on standard truck chassis, setting up in minutes, and delivering the exact reach and capacity you need. Whether you’re dealing with a delicate HVAC installation on a downtown rooftop or erecting massive steel beams on an industrial site, the right telescopic boom truck crane makes all the difference.

The choice between stand-up and swing seat models, understanding lifting capacity charts, and matching boom length to your project requirements – these aren’t just technical details. They’re the keys to project success and safety. When you factor in ground conditions, site access, and the specific demands of your lift, every decision matters.

But here’s what really sets these machines apart: the technology and safety systems that protect both operators and everyone on the job site. From advanced Load Moment Area Protection systems to 3D lift planning software, today’s cranes are smarter and safer than ever before. Combined with NCCCO certified operators who understand every nuance of crane operation, you get precision you can count on.

At Sky Point Crane, we’ve seen how the right crane can transform a challenging project into a smooth operation. Our commitment goes beyond just providing equipment – we bring three decades of experience, comprehensive lift planning, and round-the-clock availability to every job. When you’re working against deadlines or dealing with complex lifting challenges, having a partner who truly understands both the equipment and your industry makes all the difference.

The next time you’re facing a lifting challenge, the telescopic boom truck crane offers best versatility for projects of all sizes. From emergency repairs that need immediate response to carefully planned construction phases, these machines deliver when it counts.

Ready to see how the right crane can lift your next project? Contact us for expert crane services and let’s discuss how we can help you achieve your lifting goals safely and efficiently.