Why Vertical Lift Module Warehouse Solutions Matter Now

Vertical lift module warehouse systems are changing how businesses store and retrieve inventory by maximizing vertical space while minimizing floor footprint. If you’re searching for ways to optimize your warehouse storage, here’s what you need to know:

Key Benefits of Vertical Lift Module Warehouse Systems:

- Space Savings: Up to 85% reduction in floor space compared to traditional shelving

- Productivity Gains: Increase throughput by up to 2/3 by eliminating walk and search time

- Accuracy: Achieve 99.9% picking accuracy with pick-to-light technology

- Labor Cost Reduction: Cut labor costs by up to 21% through automation

- Security: Fully enclosed systems with restricted access and auditable logs

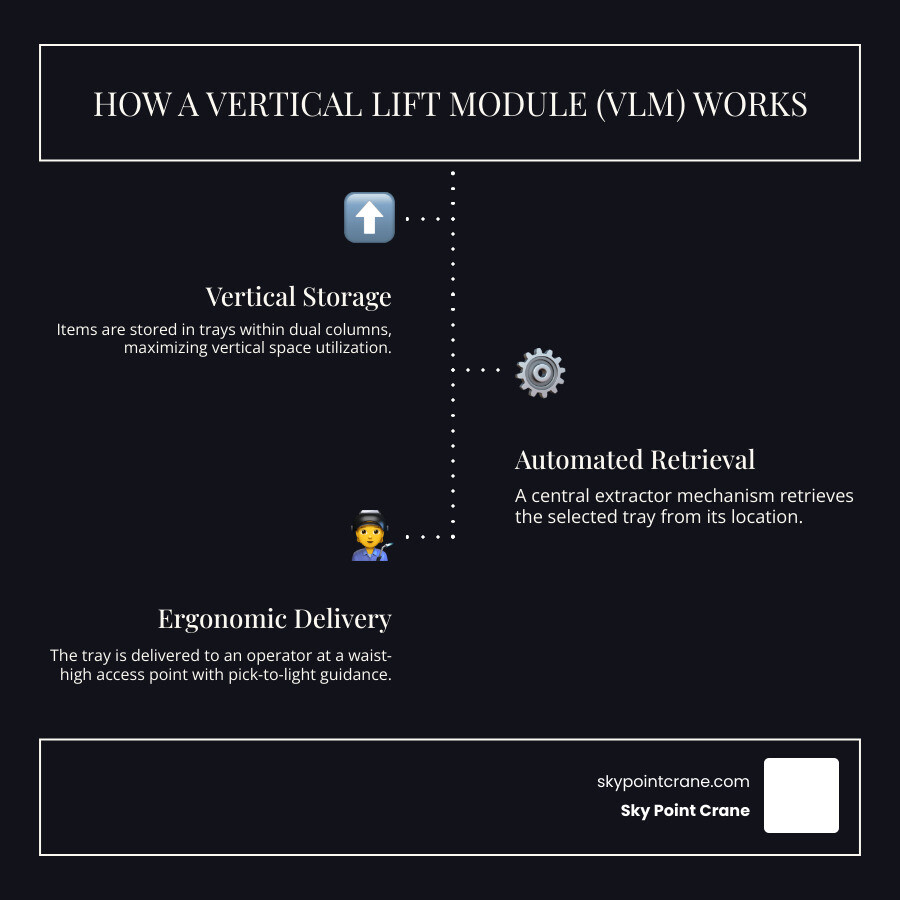

A vertical lift module (VLM) is an automated storage and retrieval system that stores inventory in two vertical columns of trays. A central extractor automatically retrieves and delivers trays to an ergonomic access point at waist height, following the goods-to-person principle. This eliminates the need for workers to walk through aisles or climb ladders to find parts.

In today’s competitive landscape, facility space costs are at record highs. Traditional storage methods spread inventory across valuable floor space, while VLMs use vertical ceiling height—often 20 to 30 feet or more—to consolidate thousands of parts in a single compact unit. The result is recovered floor space that can be converted to production areas, additional workstations, or simply eliminated from your lease footprint.

Real-world results speak volumes. Van Meter implemented 18 vertical lift modules and saw throughput increase by 25%, labor costs drop by 21%, and accuracy rise to 99.99%. Another company recovered 10,000 square feet of floor space with just two units.

I’m Dave Brocious, and over my 30+ years in manufacturing, distribution, and operations management, I’ve seen how vertical lift module warehouse solutions transform facility efficiency and drive measurable ROI. At Sky Point Crane, we provide the rigging and lifting expertise to safely install these systems and help businesses maximize their operational space.

Vertical lift module warehouse terms you need:

How a Vertical Lift Module (VLM) Works

At its heart, a vertical lift module operates on a deceptively simple yet incredibly efficient principle: storing inventory vertically and bringing the required tray directly to the operator. Think of it as a super-smart vending machine for your warehouse, but instead of snacks, it’s delivering critical parts and components right to your fingertips.

A typical VLM consists of two vertical columns of trays, one at the front and one at the back. Nestled between these columns is a central inserter/extractor. When an item is requested, this automated extractor travels vertically, identifies the correct tray, lifts it, and delivers it to an ergonomic access opening at the front of the unit. This “goods-to-person” delivery system eliminates the need for operators to walk or search for items, significantly cutting down on retrieval times.

It’s truly a marvel of modern engineering, ensuring accurate positioning and smooth operation. To see it in action, check out this video: Play Video:How does the Kardex Shuttle VLM work?

Key Technological Components and Processes

The magic behind a VLM’s seamless operation lies in its sophisticated technological components:

- Automatic Height Detection: This is where a VLM truly shines in space optimization. As items are placed on a tray, the VLM automatically measures their height. The system then uses this information to determine the optimal storage location for that tray, maximizing vertical space in precise one-inch increments. No more wasted air above shorter items!

- Dynamic Storage Allocation: Unlike traditional shelving where items have fixed locations, VLMs employ dynamic storage allocation. This means trays don’t return to a fixed spot. Instead, the system intelligently assigns the most efficient storage position based on space availability and usage patterns. Frequently accessed trays can even be stored closer to the access opening for even faster retrieval.

- Servo Motors: These are the muscles of the VLM, providing the speed, power, and accuracy needed for swift and precise vertical and horizontal movement. High-performance VLMs often feature robust servo motors, such as 10HP for vertical lift and 2HP for horizontal movement, ensuring rapid and smooth operation.

- Chain Drive Systems: Complementing the motors, durable chain drive systems ensure performance, longevity, and safety for the long haul. They are designed for continuous use, providing the reliability essential in busy warehouse environments.

- HMI Touchscreen Controls: Operators interact with the VLM through intuitive Human-Machine Interface (HMI) touchscreen displays, typically 12-inch screens. These interfaces make it easy to request trays, manage inventory, and monitor system status, even for new users.

- Sensors and Light Curtains: Safety is paramount. VLMs are equipped with advanced sensors and light curtains that prevent operation if hands or objects are in the access opening. Other safety features include door interlocks, emergency stop buttons, overload protection, and controlled motion profiles for smooth acceleration and braking.

- Intelligent Software: The brain of the operation, intelligent software minimizes pick times, streamlines material handling, and ensures the efficient flow of goods. This software is constantly calculating and optimizing, making every movement count.

Inventory Management and Control Software

The true power of a vertical lift module warehouse is releaseed when integrated with robust software solutions. These systems move beyond simple storage, offering comprehensive inventory management and control:

- Real-time Inventory Tracking: The VLM’s software provides an accurate, up-to-the-minute view of your inventory. You know exactly what you have, where it is, and when it was accessed.

- Integration with WMS/ERP: For seamless operations, VLM software is designed to integrate with existing Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems. This creates a unified platform for inventory control, order processing, and overall warehouse visibility.

- Order Batching: To maximize efficiency, the software can facilitate batch picking, allowing operators to fulfill multiple orders simultaneously from the VLM, reducing travel time and increasing throughput.

- Pick-to-Light Systems: These visual aids guide operators to the exact pick location and quantity with illuminated lights, ensuring accuracy levels of 99.9% and significantly reducing picking errors.

- Barcode Scanning: Integrated barcode scanners ensure that the right item is picked every time, verifying accuracy during both picking and replenishment processes.

- User Access Controls: For improved security, the software can restrict access to specific trays or items based on user credentials, ensuring only authorized personnel can retrieve certain inventory. All activity is logged, providing an auditable trail.

- Reporting and Analytics: The software offers detailed reporting capabilities, allowing for performance monitoring, identification of bottlenecks, and optimization opportunities. Remote diagnostic capabilities also enable proactive maintenance and system adjustments.

For more information on optimizing your storage solutions, explore our range of industrial storage solutions.

The Core Benefits of a Vertical Lift Module Warehouse

Implementing a vertical lift module warehouse system isn’t just about getting fancy new equipment; it’s about fundamentally changing your operations for the better. We’ve seen how these systems deliver tangible advantages across the board, from saving space to boosting employee morale.

How a vertical lift module warehouse optimizes space

One of the most compelling reasons businesses in Western and Central Pennsylvania, Ohio, West Virginia, and Maryland are turning to VLMs is their unparalleled ability to optimize space. Traditional shelving spreads inventory horizontally, consuming vast amounts of valuable floor space. VLMs, however, leverage the often-underused vertical height of your facility.

- Up to 85% Floor Space Savings: This isn’t just a marketing claim; it’s a statistic backed by numerous industry studies. VLMs can save up to 85% of your floor space compared to standard shelving, or achieve a total space savings of up to 80%. Imagine reclaiming nearly your entire warehouse floor!

- Utilizing Vertical Ceiling Height: By stacking trays vertically, VLMs transform unused air space into productive storage. This means you can store thousands of parts in a single, compact unit, often reaching heights of 20 to 30 meters (up to 98.4 ft) or more.

- Consolidating Inventory: VLMs allow you to consolidate inventory from multiple smaller facilities or sprawling shelving units into a single, highly dense system. This means you can expand operations internally or consolidate multiple locations without the need for physical building expansion.

- Eliminating Aisles: With goods-to-person delivery, wide aisles for forklifts and manual picking are drastically reduced or eliminated, freeing up even more floor space for production, assembly, or other critical operations.

The impact is significant. For example, a company recovered 10,000 square feet of floor space by implementing just two VLMs, demonstrating the immense potential for efficiency and cost savings. This reclaimed space can be used for higher-value activities or simply reduce your overall footprint. Read more about this case study: Case Study: 10,000 Square Feet of Recovered Floor Space.

Boosting Productivity, Accuracy, and Ergonomics

Beyond space, VLMs are champions of operational efficiency, directly impacting your workforce and bottom line.

- Increased Throughput by up to 2/3: By bringing items directly to the operator, VLMs eliminate the time-consuming tasks of walking, searching, and climbing. This can increase productivity by up to two-thirds, allowing your team to process more orders in less time. Industry studies show vertical storage solutions can increase workforce productivity by up to 85%. Operators can process even complex orders in the shortest possible time and with the highest quality level, even during peak workload times, as they don’t have to wait between jobs when retrieving parts.

- 99.9% Picking Accuracy: With integrated technologies like pick-to-light systems and barcode scanning, VLMs guide operators to the exact item and quantity, achieving accuracy levels of 99.9% or even 99.99%. This dramatically reduces mispicks, returns, and associated costs, improving customer satisfaction.

- Reduced Walk and Search Time: The goods-to-person principle means operators spend less time moving around the warehouse and more time actually picking or replenishing. This reduction in non-value-added time is a direct boost to efficiency.

- Ergonomic Waist-High Access: Trays are delivered to an ergonomic height, typically waist-high, eliminating the need for bending, reaching, or climbing ladders. This significantly reduces physical strain on employees, contributing to a safer, more comfortable work environment and potentially lowering injury rates.

- Minimized Bending and Reaching: By presenting items at an optimal height, VLMs improve worker ergonomics, reducing fatigue and making the job easier and more sustainable for your team.

We’ve seen companies like Van Meter increase throughput by 25%, reduce labor costs by 21%, and raise accuracy to an astonishing 99.99% after implementing 18 VLMs. These are not just numbers; they represent a tangible improvement in efficiency and profitability. Learn more about their success here: Case Study: Increased Throughput by 25%.

Enhancing Security and Sustainability

A vertical lift module warehouse also brings significant advantages in terms of inventory security and environmental responsibility.

- Fully Enclosed System: VLMs are fully enclosed units, protecting stored items from dust, dirt, damage, and unauthorized access. This is especially crucial for high-value, sensitive, or critical parts.

- Login-Restricted Access: Access to the VLM and its contents is typically controlled by user logins, badge readers, or other authentication methods. This means only authorized personnel can retrieve or store items, preventing theft and ensuring accountability.

- Auditable Transaction Logs: Every pick, put, and access event is logged by the VLM’s software, creating a comprehensive audit trail. This provides complete visibility into inventory movement and improves security.

- Product Protection from Dust and Damage: The enclosed nature of VLMs shields inventory from environmental factors, preserving product quality and reducing spoilage or damage.

- Reduced Energy Consumption per Pick: While VLMs use electricity, their optimized storage density and streamlined picking processes often lead to a lower energy footprint per picked item compared to traditional, less efficient methods.

- Use of Recyclable Materials: Many modern VLM manufacturers are committed to sustainability, designing their units with recyclable materials to minimize environmental impact and reduce CO2 emissions.

For solutions that offer improved security for your valuable goods, explore secure indoor industrial storage.

Implementation, ROI, and Customization

Bringing a vertical lift module warehouse into your operations in Western and Central Pennsylvania, Ohio, West Virginia, or Maryland is a strategic decision that involves careful planning and consideration. But the rewards, as we’ve discussed, are substantial.

Calculating ROI for a vertical lift module warehouse

One of the most common questions we hear is about the return on investment (ROI) for VLMs. The good news is that VLMs are known for their fast ROI, often considered one of the lowest entry points for goods-to-person automation.

The ROI is typically driven by several key factors:

- Labor Savings: By eliminating walk and search time, VLMs drastically reduce the labor hours required for picking and replenishment. This can translate to significant savings in labor costs, allowing you to reallocate personnel to higher-value tasks or manage increased volume with the same team. Van Meter, for instance, reduced labor costs by 21%.

- Space Cost Reduction: Reclaiming up to 85% of your floor space means you might delay or avoid costly warehouse expansions, reduce lease payments, or convert expensive storage areas into revenue-generating production space.

- Accuracy Improvement Savings: Fewer mispicks mean fewer returns, less rework, and higher customer satisfaction. These indirect savings can add up quickly, reducing operational expenses and improving your brand reputation.

- Throughput Gains: Increased picking speed and efficiency directly translate to higher throughput, allowing you to process more orders and potentially increase sales without increasing your operational footprint.

When a company can dually use the functionality of this equipment, the ROIs are extremely attractive. They are an extremely efficient picking solution that can carry its own operational ROI, making them a wise investment for forward-thinking businesses.

For deeper insights into optimizing your commercial storage, check out our commercial storage solutions.

Typical Applications and Industries

The versatility of vertical lift module warehouse systems makes them suitable for a wide array of applications and industries, particularly those dealing with a high volume of diverse SKUs or valuable, sensitive items. Here are some sectors that benefit immensely:

- Automotive: Storing spare parts, components, tools, and manufacturing dies for dealerships, manufacturers, and MRO (Maintenance, Repair, and Operations) facilities.

- Electronics and Components: Ideal for small, high-value, and sensitive electronic parts, often utilizing ESD (Electrostatic Discharge) safe versions to protect delicate components.

- Aerospace: Managing critical aircraft parts, tools, and maintenance supplies where precision and security are paramount.

- Medical and Pharmaceutical: Storing medical devices, medications, and lab supplies, with options for cleanroom or climate-controlled environments to maintain product integrity.

- E-commerce Fulfillment: Accelerating order picking for online retailers by streamlining access to a vast array of products, often combined with batch picking strategies for maximum throughput.

- Manufacturing MRO: Efficiently organizing and retrieving tools, raw materials, and maintenance supplies, ensuring production lines run smoothly with minimal downtime.

- Tool and Die Storage: Handling heavy and often large tools and dies, offering secure and organized storage that protects these valuable assets.

- Construction, Energy, and Healthcare: Beyond the specific examples, VLMs are proving beneficial in these broad sectors for various storage and retrieval needs, from small parts to specialized equipment.

VLMs can store items with significant weight (some trays supporting over 2,000 pounds) and dimensions (up to 10+ feet in length), making them incredibly adaptable to diverse inventory.

VLM Options, Accessories, and Dimensions

The beauty of vertical lift module warehouse systems is their adaptability. Manufacturers offer a variety of models, options, and accessories to tailor VLMs to specific operational needs.

Here’s a general overview of typical VLM specifications, though these can vary widely by manufacturer and model:

| Characteristic | Typical Range |

|---|---|

| Overall Height | 2.5 meters (100 inches) up to 30 meters (98.4 feet) |

| Overall Width | 1.5 meters (62 inches) up to 4.3 meters (172.5 inches) |

| Overall Depth | 2.3 meters (91 inches) up to 4.3 meters (171 inches) |

| Tray Width | 0.6 meters (24 inches) up to 4.05 meters (159.5 inches) or over 13 feet wide |

| Load per Tray | 90 kg (200 lbs) to 1,000 kg (2,200 lbs) |

| Overall Capacity | Up to 60,000 kg (132,000 lbs) per unit |

| Electrical | Typically 480V 3-Phase 30 Amp, or 105-125 VAC, 50-60 Hz (single phase) depending on model |

| Lift Speed | Up to 1.67 feet per second (vertical) |

| Horizontal Speed | Up to 0.83 feet per second |

Beyond these core dimensions, VLMs can be equipped with various options:

- Variable Tray Capacities: Choose trays designed for light, medium, or heavy loads, ensuring the system matches your product weight requirements.

- ESD-Safe Trays: Essential for storing sensitive electronic components, these trays prevent electrostatic discharge damage.

- Pick-to-Light Bars: Improve accuracy and speed by visually guiding operators to the exact pick location.

- Security Doors: Further improve security, providing an additional physical barrier for high-value items.

- Multi-Level Access Openings: For facilities spanning multiple floors, VLMs can be installed to allow access from different levels, integrating vertical storage across your building.

- Outdoor Installation Options: With secure, weather-protected enclosures, VLMs can even be installed outside, offering flexible storage solutions for various environments.

- Other Accessories: This can include external tray access arms, tray transporters, barcode scanners, badge readers for restricted access, custom color changes to match branding, dual tray delivery for faster throughput, and even integration with cleanroom, climate-controlled, or fire protection systems.

Frequently Asked Questions about VLMs

We understand that adopting new technology can come with questions. Here are some common inquiries we address about vertical lift module warehouse systems:

How do VLMs compare to other automated systems like vertical carousels?

While both VLMs and vertical carousels are automated vertical storage solutions, they operate differently and offer distinct advantages.

- Flexibility for Item Heights: VLMs offer superior flexibility for items of varying heights. Thanks to automatic height sensing and dynamic storage allocation, they can store loads of different heights within the same unit by adjusting shelf spacing in one-inch increments. Vertical carousels, on the other hand, typically have fixed shelf or tray heights, making them less efficient for highly variable inventory.

- Mechanism of Operation: A VLM uses a central shuttle or extractor that travels vertically to retrieve a specific tray and bring it to the operator. A vertical carousel consists of a series of carriers that rotate continuously (like a Ferris wheel) to bring the desired carrier to the access point.

- Weight Capacities: VLMs generally have higher weight capacities per tray compared to vertical carousels, making them suitable for heavier parts and tooling.

- Throughput: While both offer goods-to-person benefits, VLMs with dual shuttles can achieve continuous pick/put cycles, potentially offering higher throughput for certain applications.

If your inventory has highly variable heights and weights, a VLM offers greater space optimization and adaptability. If your items are more uniform in size, a vertical carousel might be a viable alternative.

What are the maintenance requirements for a VLM?

Like any automated machinery, VLMs require regular maintenance to ensure optimal performance and longevity. However, they are designed for durability and ease of service.

- Routine Inspections: Regular maintenance involves inspecting key components such as motors, chain drive systems, sensors, and safety mechanisms. This ensures all parts are functioning correctly and identifies potential wear and tear before it becomes an issue.

- Preventative Maintenance Plans: Most manufacturers offer comprehensive service plans that include scheduled preventative maintenance visits. These plans help maximize uptime, extend the lifespan of the unit, and ensure it operates at peak efficiency.

- Remote Diagnostics: Many modern VLMs come with remote diagnostic capabilities. This allows technicians to monitor performance, troubleshoot issues, and even make adjustments remotely, often before a problem impacts operations.

- Ease of Access: VLMs are designed with service access in mind, making it straightforward for trained technicians to perform maintenance tasks.

By adhering to recommended maintenance schedules and utilizing available service plans, you can ensure your VLM provides reliable, long-term service.

How long does it take to implement a VLM system?

The implementation timeline for a vertical lift module warehouse system can vary depending on several factors, including the complexity of the installation, the number of units, the level of customization, and the degree of software integration required.

- Standard Unit Delivery: Some manufacturers offer standard-sized VLMs that can be ready to ship in as little as 4-6 weeks, indicating a relatively quick procurement process for off-the-shelf models.

- Site Preparation: Before installation, your facility may require some site preparation, such as ensuring a level floor, adequate power supply (e.g., 480V 3-Phase 30 Amp), and sufficient overhead clearance.

- Assembly and Installation: The physical assembly and installation of the VLM unit(s) is a critical phase. This often involves specialized rigging and lifting. This is where Sky Point Crane, with our NCCCO certified operators and expertise in heavy industrial equipment installation, ensures the safe and efficient setup of your new VLM in Western and Central Pennsylvania, Ohio, West Virginia, and Maryland.

- Software Integration: Integrating the VLM’s control software with your existing WMS or ERP system is another key step. This can range from simple data exchange to more complex custom integrations.

- Training: Once installed and integrated, your team will receive training on how to operate the VLM and its software effectively.

While custom or large-scale projects will naturally take longer, the overall process can be surprisingly efficient, allowing you to reap the benefits of automated vertical storage sooner than you might think.

Transform Your Operations with Advanced Storage Solutions

The journey to an optimized and efficient warehouse begins with smart decisions about your storage infrastructure. Vertical lift module warehouse systems represent a significant leap forward in this regard, offering a powerful combination of space savings, productivity gains, accuracy improvements, improved security, and ergonomic benefits.

By strategically leveraging your facility’s vertical space, you can open up hidden potential, reduce operational costs, and empower your workforce to achieve higher levels of performance. This isn’t just about storing items; it’s about changing your entire operational workflow and gaining a strategic advantage in today’s demanding market.

At Sky Point Crane, we understand the complexities of industrial operations. We provide expert rigging and lifting services for the safe and efficient installation of heavy industrial equipment like VLMs across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. Our NCCCO certified operators and project management expertise ensure that your new vertical lift module warehouse system is installed precisely and safely, ready to revolutionize your storage capabilities.

Don’t let valuable vertical space go to waste. Contact us to learn more about our industrial storage and equipment solutions and find how we can help you open up the full potential of your facility.