Why Virtual 3D Lift Planning is Changing Construction Safety

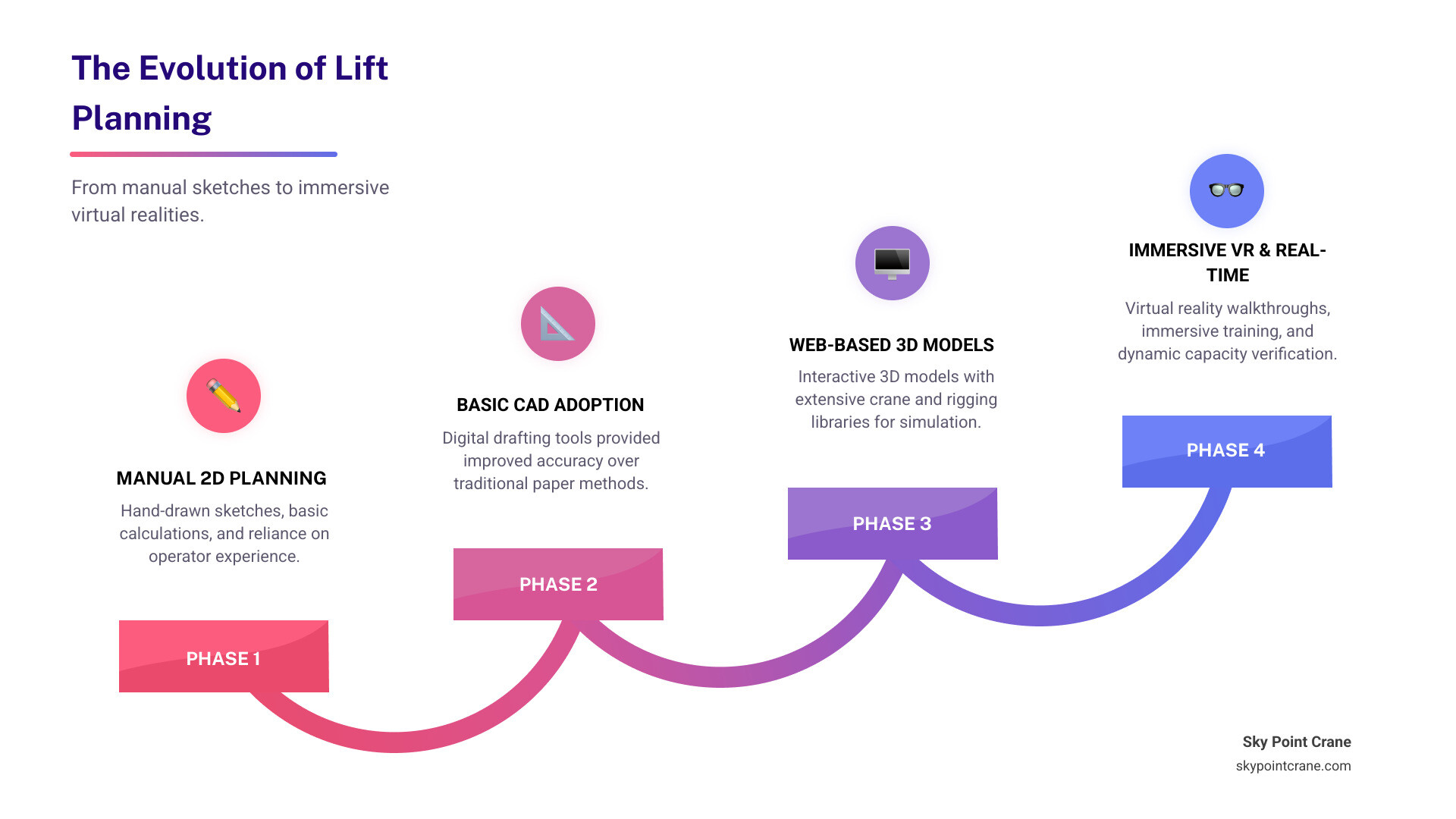

Virtual lift plan 3d technology transforms complex crane operations into predictable, safe lifts through digital simulation before equipment arrives on site. It has evolved from pencil sketches into precise digital simulations that act as a virtual dress rehearsal for every lift.

What is Virtual 3D Lift Planning?

- Digital simulation of crane operations using specialized software

- Creates accurate 3D models of cranes, loads, and job sites

- Tests lift scenarios virtually to identify potential hazards

- Generates detailed reports and visual guides for field crews

Key Benefits:

- Safety: Identifies risks like power lines, obstacles, and ground instability.

- Cost Savings: Ensures the right crane selection, eliminating expensive equipment swaps.

- Efficiency: Optimizes lift sequences to minimize downtime and labor costs.

- Communication: Provides visual clarity that all stakeholders can understand.

The technology can pay for itself in a single job. For example, Mike Larson from Andyman II LLC used 3D lift planning on a mine project to identify a critical flaw in the original plan. A malfunctioning boom-support device would have left their 550-ton crane without adequate capacity. The simulation helped them switch to a smaller gantry crane, avoiding a potential accident.

Today’s construction projects demand precision, and virtual lift plan 3d technology delivers. I’m Dave Brocious, and with 30 years in the industry, I’ve seen this technology transform crane operations. At Sky Point Crane, we’ve made detailed 3D lift planning a cornerstone of our lifting solutions throughout Western Pennsylvania, Ohio, West Virginia, and Maryland.

Must-know virtual lift plan 3d terms:

Why 3D Lift Planning is a Game-Changer for Modern Construction

Imagine planning to move a 150-ton load with a multi-million dollar crane where lives are on the line. That’s where virtual lift plan 3d technology is essential. For decades, planning relied on blueprints and experience, but even seasoned professionals can’t visualize every conflict.

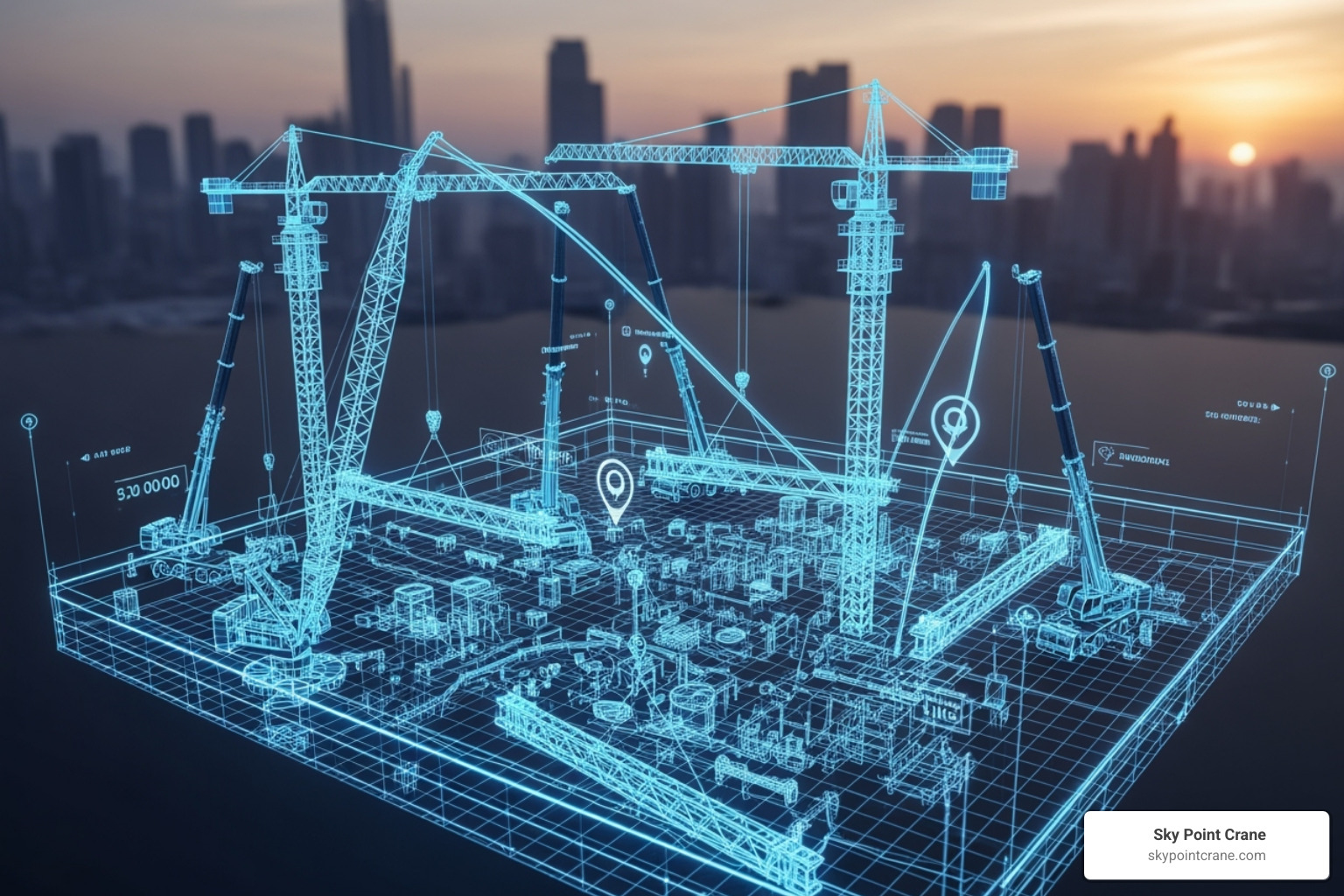

Virtual lift plan 3d software creates a complete digital replica of the lifting operation before the crane arrives. We can see the crane, load, building, and any obstacles, and watch the entire lift play out on screen. This transforms educated guesswork into precise, predictable planning. At Sky Point Crane, we’ve made this a cornerstone of our Heavy Lift Crane Planning Solutions because it prevents problems, saves money, and keeps everyone safe.

Improved Safety and Risk Mitigation

Crane accidents are devastating, and OSHA data shows collapses are a leading cause of fatalities. Virtual lift plan 3d simulations are created first and foremost for safety. Hazards like hidden power lines, unstable ground, or building overhangs that are missed on 2D drawings become obvious in a 3D simulation.

Virtual planning allows us to make mistakes on a computer screen, where they cost nothing. We can spot conflicts, identify weak soil, and catch clearance problems before mobilizing equipment. The technology verifies crane capacity, confirms rigging configurations, and checks ground bearing pressure. We simulate the entire lift, checking tail swing, boom angles, and every movement against safe parameters. This commitment to Crane Operation Safety Standards means catching problems digitally to prevent accidents physically.

Open uping Cost Efficiency and ROI

Detailed 3D lift planning saves clients thousands of dollars. We’ve seen customers avoid costly equipment swaps and reduce project timelines by days through optimized lift sequencing.

The biggest savings come from right-sizing your crane selection. Without 3D planning, there’s a tendency to over-specify larger, more expensive cranes. Virtual planning allows us to confidently select the exact crane needed. We also optimize lift sequences to minimize repositioning and reduce the number of picks, which translates directly to cost savings. The software helps identify issues that cause expensive delays, like needing crane mats or extra counterweight. For projects requiring Commercial Crane Rental, this precision delivers measurable ROI.

Streamlining Communication and Collaboration

A major benefit of virtual lift plan 3d technology is getting everyone on the same page. Traditional lift plans are full of technical jargon that can be hard for non-specialists to interpret.

Three-dimensional visualizations change that. When we show a 3D lift plan on a tablet, everyone gets it. The project manager sees the crane’s position, the site superintendent understands access route requirements, and the client can visualize the operation. This clarity aligns the entire team. During pre-lift meetings, we can walk through the sequence together, and crew members can see exactly where they need to be. This transparency builds trust and is an invaluable tool for Managing Crane Projects from Planning to Execution.

The Anatomy of a Virtual Lift Plan 3D: A Step-by-Step Workflow

Creating a virtual lift plan 3d is a methodical process that transforms project information into a validated, visual blueprint. This workflow ensures every lift is safe and on budget. For a hands-on example, see our 3D Lift Plan Tutorial.

Step 1: Gathering Critical Site and Load Data

A plan is only as good as its data. We start every virtual lift plan 3d by gathering precise details about the load and site. This includes the load’s exact weight, dimensions, and center of gravity. We conduct site surveys to measure terrain and document structures. We perform obstacle mapping for power lines, buildings, and equipment, and review geotechnical reports for ground conditions. Finally, we factor in environmental conditions like wind and weather.

Step 2: Building the Digital Twin of the Jobsite

With the data collected, we create a “digital twin” of your job site in the software. We import CAD drawings or satellite imagery to create a scaled foundation. Then, we model structures and obstacles with precise measurements. We perform crane positioning, placing the selected crane model exactly where it will sit and configuring its boom and outriggers. Finally, we complete the rigging selection, modeling the slings, shackles, and spreader bars needed for the lift, which is essential for successful Rigging Project Management.

Step 3: Running the Virtual Lift Simulation

With the digital twin complete, we simulate the entire lift sequence. The software performs clearance checks to ensure the crane, load, and rigging maintain safe distances from all obstacles, including verifying tail swing clearance. At every point, the software performs crane capacity verification against the manufacturer’s load charts. It also applies dynamic factor analysis for wind and calculates ground bearing pressure to prevent tip-overs and determine if crane mats are needed.

Step 4: Generating and Sharing Actionable Reports

After validation, we generate comprehensive reports that serve as a roadmap for execution. These practical tools are designed for everyone involved. Comprehensive lift reports include all details, while visual renderings (images and videos) provide an intuitive understanding of the lift. For the field crew, we create simplified field documents for easy on-site reference. These plans are shared digitally with all stakeholders, representing 3D Lift Planning The Future of Crane Operations and turning manual calculations into a streamlined, accurate process.

Key Features and Considerations for Lift Planning Software

Not all virtual lift plan 3d software is created equal. Choosing the right platform is critical for effective planning. At Sky Point Crane, we know which features matter for supporting our Specialized Lifting Equipment operations.

Essential Features to Look For

Effective software starts with key features:

- Extensive Crane Library: A database with load charts and graphics for hundreds of crane models (some have over 900) is essential for planning with the exact equipment on site.

- Rigging Design Tools: The software must model complex rigging setups and include a weight summation feature to accurately calculate the total load.

- Ground Bearing Pressure Calculation: This safety-critical feature calculates and visualizes the pressure each outrigger exerts on the ground, preventing tip-overs.

- Site Modeling and Simulation: The ability to import CAD or satellite imagery, model obstacles, and run simulations to verify clearances and capacities is fundamental.

- User-Friendly Interface: Powerful software is useless if it’s not accessible. A user-friendly, step-by-step process is a significant advantage.

Choosing Your Platform: Browser-Based vs. Desktop

The choice between browser-based and desktop software depends on your workflow. Browser-based platforms offer flexibility, automatic updates, and easy collaboration from anywhere with an internet connection. Desktop applications provide more processing power for complex simulations, work offline, and often integrate directly with CAD tools, though they may require more robust hardware.

| Feature | Browser-Based Platforms | Desktop Applications |

|---|---|---|

| Accessibility | Work from anywhere with internet; cloud-based flexibility | Requires installation; works offline |

| Updates | Automatic updates; always current | Manual updates required |

| Collaboration | Easy real-time sharing via cloud | Requires file sharing or network setup |

| Complexity | User-friendly, step-by-step design | Handles highly complex simulations; steeper learning curve |

| Integration | API connections to cloud project tools | Direct CAD integration; powerful local processing |

| Hardware Needs | Less demanding; relies on server processing | Requires robust hardware for best performance |

| Cost Model | Subscription-based; some sponsored cranes free | One-time purchase or subscription; trial licenses available |

Cost models also differ, with subscriptions common for browser-based tools and one-time purchases or trials for desktop apps. To learn more, you can listen to experts discuss lift planning approaches.

Integrating with Your Project Ecosystem

A virtual lift plan 3d should integrate with your other project management tools. Look for software that can export to BIM platforms (like BIM 360) and link to scheduling software (like Primavera P6 or MS Project). This creates a complete project picture and connects the lift plan to the overall timeline. Good document control and field mobility are also key, allowing teams to access the latest plans on tablets or smartphones from the job site. This makes the lift plan a living document for effective Crane Project Management.

From Plan to Reality: Best Practices for Safety and Execution

A virtual lift plan 3d is meaningless if it can’t be translated into a safe lift. The gap between digital perfection and jobsite reality is where accidents happen. At Sky Point Crane, we bridge that gap by pairing technology with field-tested execution strategies, anchored in our strict Crane Safety Protocols.

The most sophisticated simulation can’t account for human error or corner-cutting. But when you combine advanced planning with disciplined execution, you create a safety system that’s truly bulletproof.

The Ground Up: Mastering Ground Bearing Pressure

Nothing is more critical than the ground beneath a crane. Ground bearing pressure is a vital safety factor. OSHA Standard 1926.1402 makes the job site’s controlling entity responsible for ground preparations. Our virtual lift plan 3d process includes detailed soil data analysis from geotechnical reports to calculate pressure at each outrigger. We then design appropriate matting solutions to distribute the load safely. This meticulous approach is central to our Crane Safety Standards.

Common Pitfalls to Avoid in your virtual lift plan 3d

Even with the best software, vigilance is key. Avoid these common pitfalls:

- Incorrect Crane Model: Always verify the crane model and configuration in the plan match the actual equipment.

- Forgetting Rigging Weight: Use weight summation tools to account for slings, shackles, and spreader bars.

- Improper Sling Angles: Keep sling angles above 45 degrees to avoid dramatic increases in tension.

- Overlooking Dynamic Loads: Account for forces from wind or sudden movements by applying contingency factors.

- Ignoring Tail Swing Clearance: Simulate a full 360-degree swing to ensure the counterweight clears all obstacles.

The Future is Now: VR and Advanced Simulation in your virtual lift plan 3d

Lift planning technology continues to evolve with Virtual Reality (VR) and advanced simulations. These tools allow crews to practice complex lifts in a safe, virtual environment. Walking through a job site in VR provides a true sense of scale and helps stakeholders understand the plan on a deeper level. This technology is proven to reveal critical flaws and save lives. To see what’s possible, explore VR simulation technology.

Mastering the Craft: Training and Resources

Adopting virtual lift plan 3d technology means investing in your people. A powerful tool is useless if your team isn’t trained to use it effectively. Resources include online classes from software providers, manufacturer training, and industry forums. Combining technology with the knowledge of experienced professionals is the key to success and underscores The Importance of Investing in Crane Safety Training for Your Team.

Frequently Asked Questions about Virtual 3D Lift Planning

Here are answers to some of the most common questions we receive about virtual lift plan 3d technology.

What information is needed to create a 3D lift plan?

To create an accurate virtual lift plan 3d, we need comprehensive data, including:

- Load Details: Exact weight, dimensions, and center of gravity.

- Site Plans: Accurate drawings or models showing terrain and elevations.

- Obstacle Locations: All permanent and temporary obstructions, like buildings, power lines, and equipment.

- Geotechnical Data: Information on ground conditions and soil bearing capacity for crane stability.

- Crane Specifications: The exact model, configuration, counterweights, and outrigger setup.

- Rigging Details: All slings, shackles, and spreader bars to be used.

Is 3D lift planning only for large, complex projects?

No. While essential for complex lifts, virtual lift plan 3d technology benefits nearly every crane operation. For straightforward lifts, it helps optimize crane choice (avoiding unnecessary costs), ensures safety margins are maintained, and improves efficiency by streamlining the lift sequence. The accessibility of modern software makes it a valuable tool for any project, big or small, providing peace of mind and making every job safer.

Who is responsible for the accuracy of a 3D lift plan?

Accuracy is a collaborative effort.

- The lift planner (an engineer or specialist) is responsible for designing the plan and ensuring it meets all safety standards.

- The controlling entity (general contractor or site owner) is responsible for providing accurate site data and ensuring ground conditions are prepared as specified.

- The crane operator has the final authority. They must use their professional judgment to review the plan and have the responsibility to stop the lift if conditions are not safe.

At Sky Point Crane, we view the 3D lift plan as a central document that brings all these parties together, creating a shared understanding and commitment to safety. When everyone knows their role and the plan is clear, that’s when the magic happens—smooth, safe lifts that look effortless because they were planned to be exactly that.

Conclusion

Virtual lift plan 3d technology has moved crane operations from guesswork to an era where every lift can be rehearsed and perfected. The benefits are clear: dramatic improvements in safety, soaring efficiency, effortless communication, and real cost savings.

What was once cutting-edge is now the industry standard, expected by contractors and valued for the peace of mind it provides. At Sky Point Crane, we have made this technology a cornerstone of how we serve Western and Central Pennsylvania, Ohio, West Virginia, and Maryland. Our NCCCO certified operators arrive with a detailed, validated roadmap for your project.

We combine state-of-the-art virtual lift plan 3d capabilities with decades of real-world experience. This blend of technology and expertise allows us to tackle any lift with confidence. Every project deserves this level of planning, and every team deserves to go home safe.

Ready to experience what modern crane planning can do for your next project?