Understanding the Versatile Boom Truck Crane

A boom truck crane is a specialized vehicle combining a hydraulic crane, flatbed truck, and personnel hoist into one versatile lifting solution. These machines offer best flexibility for construction, utility work, and industrial applications. Unlike traditional cranes, they travel on public roads at highway speeds, lift loads up to 60 tons, and feature boom lengths over 180 feet. The integrated flatbed allows for material transport, while outriggers provide stability during lifts.

What makes these machines so valuable is their ability to replace multiple pieces of equipment. Instead of needing a separate crane, transport truck, and personnel lift, one boom truck crane handles all three functions, boosting project efficiency and safety.

Boom truck crane terminology:

What is a Boom Truck?

A boom truck crane is a multi-functional machine that mounts a hydraulic crane on a commercial truck chassis. This “all-in-one” design makes it road-legal, allowing it to move between job sites without additional transport. On a busy site, a single boom truck crane can lift materials, transport them on its flatbed, and hoist personnel, which streamlines logistics, reduces rental costs, and minimizes site congestion. This versatility is key to working smarter and more efficiently.

For more information on how specialized equipment like this can benefit your projects, check out our insights on Specialized Lifting Equipment.

Key Components and Features

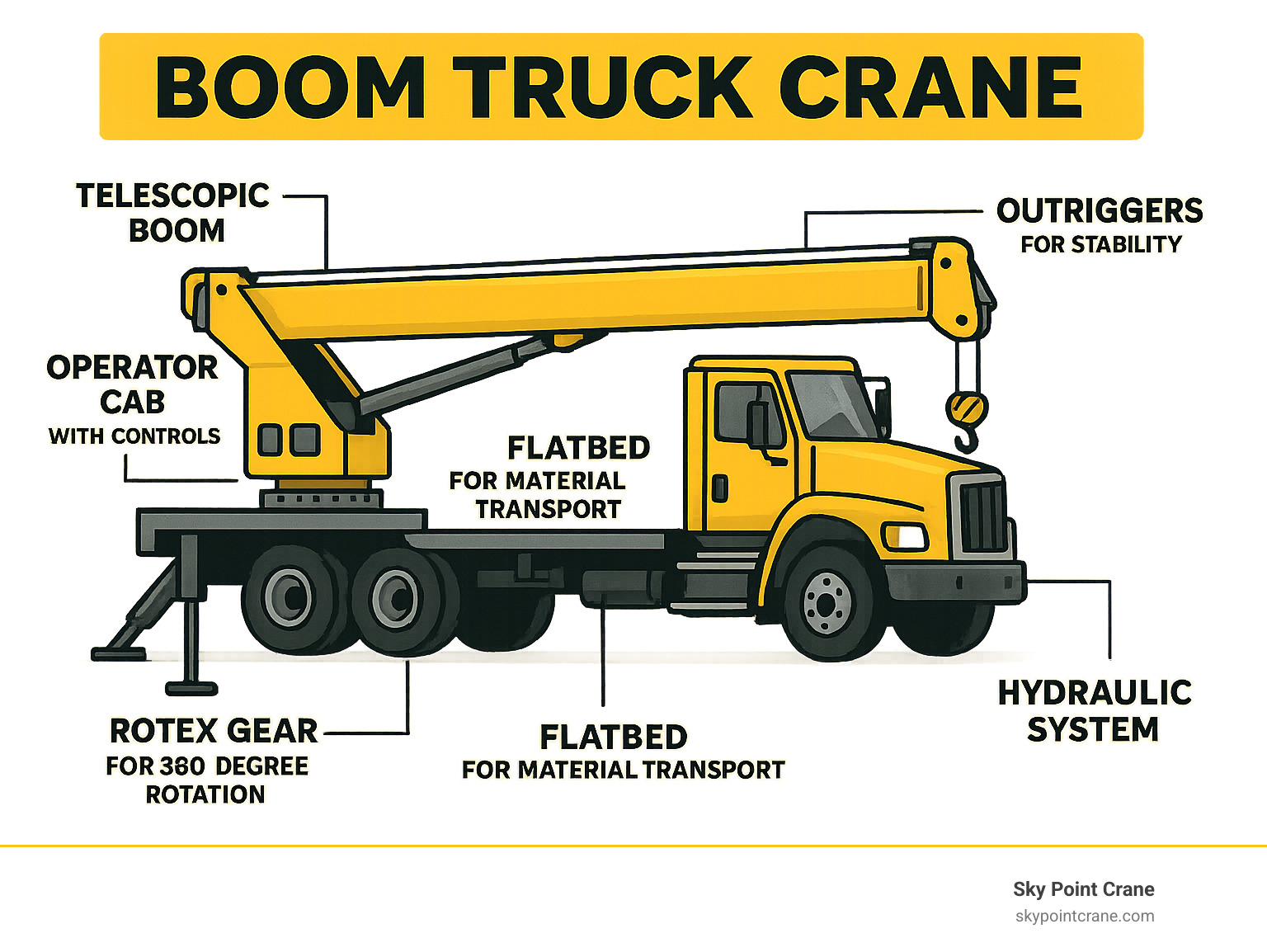

Understanding a boom truck crane’s components reveals its engineering for performance and safety:

- Hydraulic Boom: The primary lifting arm, either telescopic for straight-line lifting or articulated (knuckle boom) for maneuvering around obstacles.

- Jib: An extendable arm attached to the boom for additional reach.

- Outriggers: Hydraulic legs that extend from the chassis to provide a wide, stable base during heavy lifts.

- Rotex Gear: Allows the boom to rotate 360 degrees for maximum flexibility without repositioning the truck.

- Operator Cab: An enclosed or open seat with precise controls for smooth operation.

- Flatbed: A platform for transporting materials, adding to the machine’s utility.

- Load Block: The heavy assembly at the end of the boom where the hook is attached.

These components work together, powered by a robust hydraulic system, to make the boom truck crane an incredibly capable tool.

For more details on specific models and their features, you can explore our information on National Boom Truck Cranes.

Boom Truck vs. Other Cranes

While a boom truck crane is a type of crane, it differs from other heavy-duty equipment like hydraulic truck cranes or all-terrain cranes. Understanding these differences is key to selecting the right tool.

| Feature | Boom Truck Crane | Hydraulic Truck Crane | All-Terrain Crane |

|---|---|---|---|

| Mobility | High (Road legal, travels at highway speeds, agile) | Moderate (Road legal, but less agile, heavier) | High (Road legal, multi-axle, crab steer) |

| Capacity | Lower (Few tons up to 60 tons, typically under 54) | High (30-500 tons, often exceeding 54 tons) | Very High (Hundreds of tons) |

| Setup Time | Quick (Relatively fast to deploy outriggers) | Longer (More complex setup, larger footprint) | Moderate to Longer (More complex, but versatile) |

| Ideal Use Case | Versatile, transport, lighter lifts, tight spaces, utility work, HVAC, small construction | Heavy construction, large objects, rough terrain, industrial projects | Versatile, any terrain, large projects, long distances |

Unlike larger cranes that use heavy counterweights, a boom truck crane achieves stability through its chassis and outriggers, contributing to its lighter weight and mobility. While its lifting power is impressive for its class (up to 60 tons), dedicated hydraulic truck cranes are built for much heavier lifts. Essentially, a boom truck crane is a truck with a crane, emphasizing transport and versatility, whereas larger cranes are purpose-built for heavy lifting.

For a broader understanding of various mobile lifting solutions, explore our section on Mobile Cranes.

Common Applications and Industries Served

The versatility of the boom truck crane makes it an indispensable asset across a wide array of industries. From busy construction sites to intricate utility work, these machines help businesses get the job done safely and efficiently. Let’s look at the different types and where they shine.

Telescopic Boom Trucks

The telescopic boom truck crane is a workhorse for jobs needing direct, straight-line lifting. Its extendable arm is perfect for:

- Construction sites: Lifting framing materials, placing roof trusses, and assisting with steel erection.

- Roofing projects: Hoisting shingles, insulation, and other supplies to high rooftops quickly and safely.

Their powerful design and impressive reach make them ideal for getting materials directly overhead.

For more on how we use cranes for structural work, visit our page on Crane Rental for Steel Erection.

Articulating (Knuckle) Boom Trucks

Articulating (knuckle) boom trucks offer superior finesse and flexibility. With multiple joints, their “bendy” design provides incredible maneuverability, allowing the crane to reach over, under, and around obstacles. This makes them perfect for:

- Lifting in tight spaces: Reaching over fences or into crowded industrial and urban environments.

- Loading and unloading: Efficiently picking and placing materials with precision, especially awkwardly shaped items.

- Material delivery: Placing materials exactly where needed, even through narrow openings.

Sometimes, these come equipped with personnel buckets for specialized work. Learn more about their functionality on our Boom Truck with Bucket page.

Industries That Rely on the Boom Truck Crane

The boom truck crane is a vital tool across a range of sectors. Key industries that depend on our services include:

- Construction: Lifting materials, setting trusses, and aiding in steel erection on residential and commercial projects.

- Utilities: Installing and maintaining power lines, street lights, and other infrastructure, often with bucket truck configurations. Learn about Crane Use in the Construction of Electrical Transmission Lines.

- Telecommunications: Installing and servicing cell towers and antennas with precision at height. See our insights on Crane Use in the Telecom Industry.

- HVAC Installation: Lifting heavy heating and cooling units onto rooftops efficiently.

- Tree Removal & Landscaping: Safely removing large branches or entire trees in tight residential areas. Find out more about Crane Rental for Tree Removal.

- Oil & Gas: Supporting drilling operations, lifting machinery, and handling heavy components like pump jacks.

- Commercial Roofing: Lifting large quantities of roofing materials to the tops of tall buildings.

- Municipalities: Performing general maintenance, sign installation, and light pole repair.

Selecting the Right Boom Truck for Your Project

Choosing the right boom truck crane is about matching the machine’s capabilities to your project’s specific needs to ensure safety, efficiency, and cost-effectiveness. The right selection can turn a challenging project into a smooth operation.

Key Specifications to Consider

When selecting a boom truck crane, we focus on the specifications that matter for your project’s success:

- Lifting Capacity: The maximum weight the crane can handle, typically ranging from a few tons up to 60 tons.

- Boom Length and Reach: Determines how high and far the crane can work. For example, the National Crane NBT60 boom extends to 128 feet.

- Tip Height: The maximum height the boom tip can reach, with some models like the NBT60 reaching up to 179 feet with a jib.

- Load Charts: The safety bible for any lift, these charts detail how much weight the crane can lift at different angles and distances. Our certified operators follow them precisely.

- Outrigger Spread: The footprint of the deployed outriggers, which defines the crane’s stability. We always consider site space when planning deployment.

For more insights on how proper equipment selection maximizes project efficiency, check out our guide on Maximizing Efficiency on Site.

Impact on Project Efficiency and Cost

Selecting the right boom truck crane has a significant positive financial impact. Comparing rental versus purchase, renting eliminates hefty upfront costs (new cranes can cost $15,000 to $500,000+), depreciation, and maintenance. It also provides access to the right machine for every job.

- Personnel Efficiency: One boom truck crane team handles lifting, transport, and personnel hoisting, reducing labor costs and simplifying coordination.

- Transport Costs: Boom trucks drive at highway speeds, eliminating the need for expensive heavy-haul trailers and special permits, saving thousands in transportation fees.

- Fuel Efficiency: Modern models offer impressive fuel efficiency, keeping operational costs low.

The combined savings from reduced equipment needs, simplified logistics, and eliminated transport costs are substantial.

Dive deeper into the financial considerations with our detailed analysis of Truck Crane Rental vs Purchase and explore The Economics of Crane Rentals.

The Role of Advanced Lift Planning

Even the best boom truck crane needs a solid plan. Our advanced lift planning services ensure success through:

- Site Assessment: We thoroughly evaluate terrain, obstacles, and available space for crane setup.

- Obstacle Avoidance: We identify and map safe paths for the crane and load, avoiding power lines, structures, and other obstructions to prevent delays.

- Strategic Crane Placement: We calculate the optimal position to maximize reach and capacity while minimizing setup time and ensuring proper ground bearing pressure.

- 3D Lift Planning: We use technology to create detailed virtual simulations of the lift, allowing us to test and confirm the safest, most efficient plan before the crane arrives on site.

This comprehensive approach sets your project up for success from day one. Learn more about our advanced planning capabilities through our 3D Lift Planning and Heavy Lift Crane Planning Solutions services.

Safety, Maintenance, and Operator Certification

At Sky Point Crane, safety is the heart of everything we do. Operating a powerful boom truck crane requires strict safety protocols, rigorous maintenance, and highly skilled operators. We ensure all three are rock solid for every project.

Essential Safety Protocols for a Boom Truck Crane

We are committed to the highest safety standards to protect our crew, your property, and everyone on site. Our protocols include:

- Pre-Lift Checks: Operators conduct thorough daily inspections of all critical components, including hydraulics, controls, cables, and outriggers. This is supplemented by annual third-party inspections.

- Understanding Load Limits: Our operators are expertly trained to read and strictly follow the crane’s load charts. We never exceed the rated capacity, and our cranes are equipped with systems like Load Moment Indicators (LMI) for real-time feedback.

- Monitoring Weather Conditions: We closely monitor for high winds, rain, or lightning. Lifts are postponed or adjusted if conditions become unsafe.

- Ensuring Ground Stability: We carefully assess the ground and use mats or cribbing to ensure proper outrigger deployment and prevent sinking or instability.

Our commitment to safety is unwavering, and we follow all OSHA regulations, including OSHA 1926.1412.

For more on our safety commitment, please check out our Crane and Rigging Safety page. You can also find general Information on safety standards and specific Crane Operation Safety Standards.

Operator Certification and Training

The skill of the operator is just as important as the equipment. We pride ourselves on having the most capable and well-trained operators in the industry. All our operators are:

- NCCCO Certified: They have passed rigorous training and testing, proving their expertise in mobile crane operation—the gold standard for safety and skill.

- CDL Licensed: As boom truck cranes are road-legal, our operators hold the necessary CDL driver requirements to transport equipment safely.

- Proficient in Rigging and Signaling: Our team is skilled in properly securing loads and communicating clearly with ground crews to ensure every lift is a coordinated, safe effort.

- Committed to Continuous Education: We invest in ongoing training to keep our team updated on the latest technologies, safety practices, and operational techniques.

You can learn more about our commitment to operator excellence on our NCCCO Certified Crane Operators page.

Maintenance Best Practices

A well-maintained boom truck crane is a safe and reliable partner. Our thorough maintenance program ensures our fleet is always in peak condition.

- Routine Inspections: Our cranes undergo rigorous, scheduled inspections by qualified technicians as part of a preventative maintenance plan to catch issues early.

- Hydraulic Fluid Checks: We regularly monitor hydraulic fluid levels and quality to keep the system running smoothly and prevent component failure.

- Structural Integrity: We carefully examine the boom, chassis, outriggers, and welds for any signs of wear, fatigue, or damage.

- Following Manufacturer Guidelines: We strictly adhere to the maintenance schedules and procedures recommended by the crane manufacturers to maximize lifespan and uphold safety ratings.

Our proactive approach to maintenance means less downtime, improved reliability, and the highest safety standards for every lift.

For more insights into how we ensure equipment safety, read more on Crane Rental Company Safety Protocols.

The Future of Boom Truck Technology

The world of boom truck crane technology is constantly evolving, promising to make operations even more efficient, safer, and sustainable.

Key technological advancements include improved hydraulic systems for smoother, more precise lifts and advanced computer systems with intuitive controls that help operators work with greater accuracy. These innovations are paired with improved safety features, such as standard load monitoring and stability control systems (like Work Area Definition Systems, or WADS), which provide real-time feedback to prevent overloading and keep every lift within safe limits.

Manufacturers are also focusing on environmental considerations, developing more fuel-efficient engines and exploring alternative power sources to reduce emissions. The future also includes telematics and automation. Telematics allows for remote monitoring of crane performance and diagnostics, minimizing downtime. While skilled operators remain essential, increased automation for repetitive tasks will further improve precision and safety.

These exciting changes are making the boom truck crane an even more valuable and capable tool for a wide range of jobs. To dive deeper into how these cranes are evolving, you can check out this article: The evolution of boom trucks.

Your Partner for Efficient and Safe Lifting

As we’ve explored, the boom truck crane is a game-changer, offering best versatility, efficiency, and safety. By combining a crane, truck, and personnel lift into one mobile unit, it provides a smart, cost-effective solution for a huge range of lifting applications.

At Sky Point Crane, your project’s success is our goal. We provide more than just equipment; we deliver comprehensive lifting solutions backed by decades of experience. Serving Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, we offer 24/7 crane services to tackle your toughest challenges. Our commitment is to your project’s safety and smooth execution. Every boom truck crane operator is NCCCO certified, our fleet is rigorously maintained, and our advanced 3D Lift Planning services ensure every lift is carefully planned to avoid surprises.

When you partner with Sky Point Crane, you gain a dedicated, professional, and reliable team committed to making your lifting operations as smooth, safe, and cost-effective as possible. We are your trusted partner for all crane and rigging needs.

Ready to see how a boom truck crane can lift your next project? Contact us for reliable crane services today to discuss how our solutions can help you achieve your goals.