Why Cranes Used For Power Plants Are Essential to America’s Energy Infrastructure

Cranes Used For Power Plants are the unsung heroes of America’s energy infrastructure. These specialized lifting machines are essential throughout a power plant’s entire lifecycle, from construction and maintenance to modernization and decommissioning.

Key Applications of Power Plant Cranes:

- Construction Phase: Installing turbines, generators, boilers, and cooling towers

- Maintenance Operations: Turbine disassembly, rotor removal, and component replacement during outages

- Material Handling: Unloading coal, limestone, and other bulk materials from barges and rail cars

- Modernization: Upgrading outdated equipment and installing new technology

- Decommissioning: Dismantling structures and removing heavy components for repurposing

From a 500-ton crawler crane positioning a reactor vessel to a polar crane performing fuel assembly, these machines operate in demanding environments. Precision is critical—as one industry expert noted, “If a crane breaks during a planned outage, it creates a major problem” for the power grid.

The stakes are incredibly high. Power plants demand 100% reliability, safety, and accuracy. Whether it’s the millimetric precision for nuclear components or lifting 335-ton boiler sections, cranes must perform flawlessly in harsh conditions like extreme temperatures, dust, and humidity.

I’m Dave Brocious, and with over 30 years in the energy industry, I’ve seen how critical Cranes Used For Power Plants are. At Sky Point Crane, we know there’s no room for error when lives and livelihoods depend on keeping the power flowing.

The Crane’s Role Across the Power Plant Lifecycle

From construction to decommissioning, Cranes Used For Power Plants are active participants throughout a power plant’s entire lifecycle. They are essential in every chapter, from groundbreaking to the final dismantling.

At Sky Point Crane, we know successful projects require more than just the right equipment. Our Heavy Lift Crane Planning Solutions help managers plan every detail before a lift, saving time and money. The initial purchase price of a crane is often the smallest part of its lifetime expense; maintenance, repairs, and upgrades add up. We focus on delivering reliable performance and expert guidance to ensure our services make your project more profitable.

From Groundbreaking to Going Online: Construction and Assembly

Building a power plant involves coordinating massive cranes to handle components weighing hundreds of tons. Cranes Used For Power Plants in construction must manage a variety of tasks, each requiring specific capabilities. Component installation is the real heavy lifting, involving positioning massive turbines and generators with millimetric precision. Stator and rotor assembly requires delicate handling of these heavy, precisely engineered components.

Boiler re-tubing is a unique challenge, maneuvering heavy steel components through tight spaces around existing infrastructure. Turbine installation demands similar precision on an even larger scale. Structural steel erection forms the backbone of the facility, and these massive structures must be positioned perfectly to support all the heavy equipment.

We also handle specialized projects like our Crane Use in the Construction of Electrical Transmission Lines, ensuring that power plants can deliver their electricity to the communities that need it.

Keeping the Lights On: Maintenance, Outages, and Modernization

Once a plant is operational, crane work intensifies. During scheduled outages, every hour counts, and cranes work around the clock to get the plant back online quickly. Turbine maintenance is highly complex, requiring careful disassembly and reassembly to access internal parts. Component replacement during outages ranges from small parts to sections weighing hundreds of tons.

Transformer core removal is a specialty task requiring power and finesse to handle heavy, valuable cores. Modernizing equipment involves removing outdated components and installing new ones to keep plants competitive.

- Turbine disassembly and reassembly

- Boiler component replacement

- Generator rotor removal

- Transformer maintenance

Minimizing downtime is key to successful maintenance. An offline plant loses revenue, so we work with operators to ensure our lifting operations stay on schedule and avoid delays.

The Final Stage: Decommissioning and Repurposing

When a power plant reaches its end of life, decommissioning isn’t just demolition. It involves carefully dismantling structures so valuable components can be repurposed. Removing heavy equipment requires the same precision as construction, just in reverse. Repurposing components is vital for sustainability and cost-effectiveness, allowing parts like transformer cores to be reused.

Site remediation is the final step, preparing the land for new uses. This can mean converting the site for new power generation, like the Crane Clean Energy Center, which transformed an old site into a modern, clean energy facility.

Throughout this entire lifecycle, Cranes Used For Power Plants remain essential tools for keeping America’s energy infrastructure running smoothly.

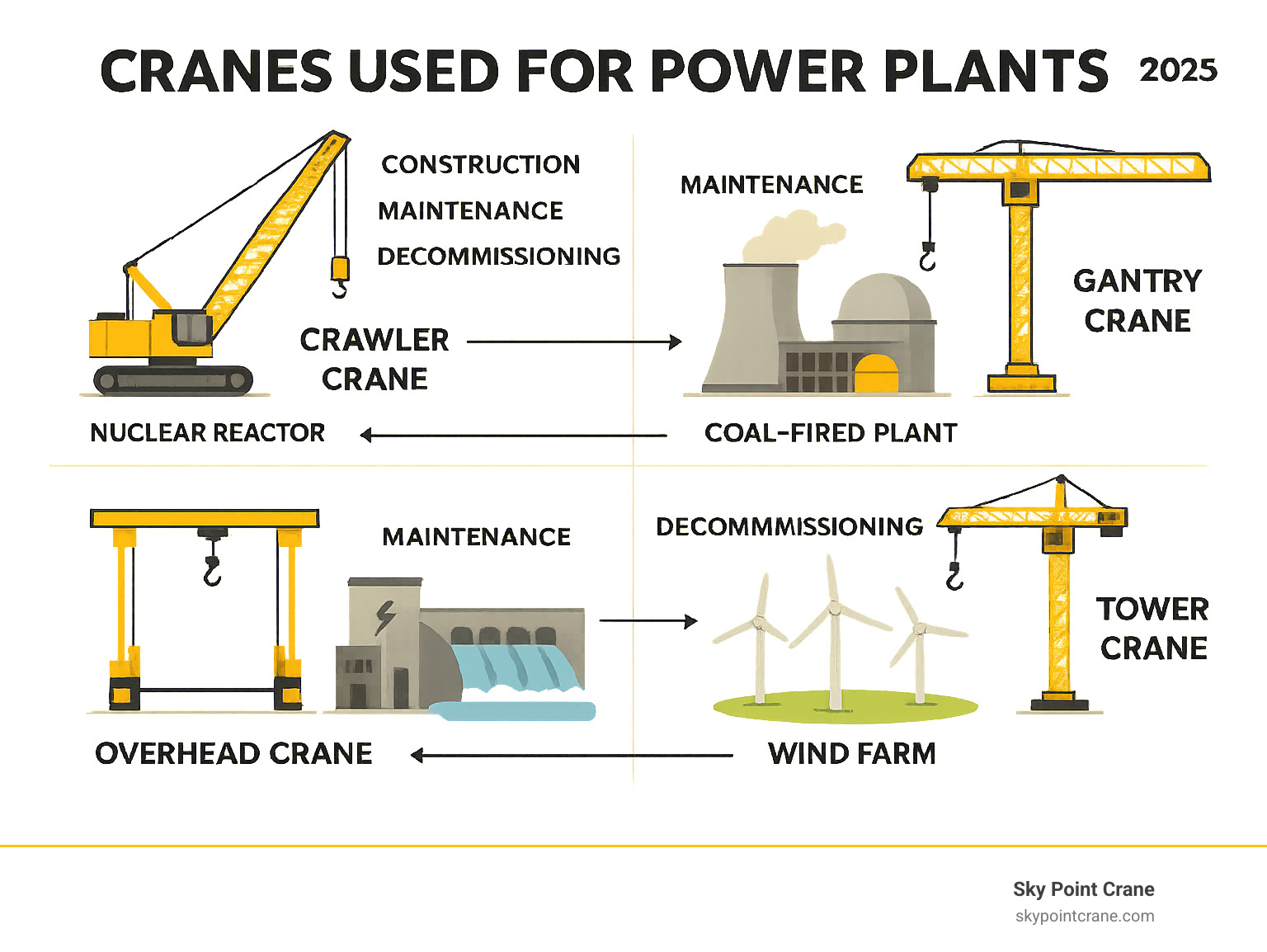

Matching the Right Cranes Used For Power Plants to the Facility

Choosing the right crane for a power plant is a critical decision. Each type of power facility has unique challenges and lifting needs that require specialized equipment and expertise. At Sky Point Crane, understanding these unique demands is key to success. We provide comprehensive solutions, including Specialized Lifting Equipment custom to your specific power generation needs.

The principle is simple: the right tool for the job. A crawler crane ideal for wind turbine erection is wrong for delicate nuclear fuel handling, and a polar crane is overkill for a solar farm. Selecting the right Cranes Used For Power Plants is crucial.

| Crane Type | Primary Applications | Thermal Plants | Nuclear Plants | Hydro Plants | Renewables (Wind/Solar) |

|---|---|---|---|---|---|

| Crawler Cranes | Heavy construction, large component lifts, long-term projects | High-capacity boiler/turbine installation, heavy material handling | Reactor vessel placement, containment building construction | Dam construction, penstock installation | Wind turbine erection, large solar farm structural work |

| Gantry Cranes | Turbine installation/servicing, bulk material handling, intake gates | Turbine hall operations, coal/petcoke unloading | N/A (Polar cranes for containment) | Intake/draft tube gate lifting, powerhouse operations | N/A |

| Overhead Cranes | Indoor maintenance, precise assembly, workshop tasks | Turbine hall maintenance, general workshop lifts | Fuel handling (in some areas), general maintenance within buildings | Powerhouse maintenance, generator assembly | N/A (unless for workshop maintenance) |

| Tower Cranes | High-rise construction, cooling towers, long-reach placements | Cooling tower construction, boiler structure erection | Containment building construction, tall structures | N/A (for general construction) | N/A (for general construction) |

| Mobile Cranes (Hydraulic/Rough Terrain) | Versatile support, quick setups, outages, smaller lifts | General maintenance, equipment replacement during outages | Auxiliary building support, non-critical lifts | General maintenance, small component handling | Solar panel placement, wind turbine component maintenance |

Thermal and Natural Gas Power Plants

Thermal and natural gas plants are harsh environments with heat and dust. They demand tough, durable Cranes Used For Power Plants designed for the long haul. Boiler room and turbine hall cranes are the workhorses, handling components up to 1,000 tons with millimeter precision. Bulk material handlers with massive clamshell buckets can unload 1,300 tons of limestone or petcoke per hour, while coal handling cranes face abrasive materials and extreme temperatures to maintain a steady fuel supply. Our expertise in Crane Use in Natural Gas Power Plants ensures these facilities operate efficiently.

The Unique Demands of Nuclear Power Plants

Nuclear facilities demand absolute perfection with zero margin for error. The requirements for Cranes Used For Power Plants in these environments are the most stringent. Polar cranes are specialized machines on circular runways inside containment buildings, handling tasks like fuel assembly. Their key feature is single-failure-proof engineering, ensuring that if any single component fails, the load will not drop. Seismic durability and fail-safe controls are also non-negotiable. Millimetric precision is absolutely essential when working with nuclear fuel assemblies or positioning reactor components.

Using Nature: Hydroelectric and Renewable Energy

Hydroelectric and renewable energy projects combine massive scale with environmental sensitivity, creating unique lifting challenges. Intake gantry cranes at hydroelectric facilities manage massive water flow gates in wet, corrosive environments. In remote hydro plants, powerhouse overhead cranes are often the only equipment for turbine servicing, making reliability critical. For renewables, wind turbine nacelle hoists are compact hoists that perform maintenance hundreds of feet in the air, while tower cranes are used for solar panel installation to meet tight construction deadlines. Our experience supports the clean energy future, as seen in projects like the Charles P. Crane Generating Station.

Precision and Safety: The Non-Negotiables of Power Plant Lifts

When working with Cranes Used For Power Plants, there is no room for error. In power generation, precision and safety are paramount, as a single mistake can cost millions, cause widespread power outages, or put lives at risk. At Sky Point Crane, we’ve seen the consequences of cutting corners, which is why we maintain a zero-incident track record.

Power plants present challenging conditions, from extreme dust and humidity to ice at high-altitude sites. Regardless of the environment, our Cranes Used For Power Plants must operate safely and reliably, especially during time-sensitive outages where downtime is extremely costly.

Critical Safety and Regulatory Standards

Operating Cranes Used For Power Plants requires adhering to stringent safety standards beyond basic OSHA compliance. Every Sky Point Crane operator holds current NCCCO certification with over 15 years of experience. Learn more about our NCCCO Certified Crane Operators.

When working near power lines, our cranes use load-bearing insulators on the load line to protect our crew from electrocution. For critical applications like nuclear plants, we use cranes with redundant systems and fail-safe controls, as single points of failure are unacceptable. Our approach to Crane Operation Safety Standards uses continuous-duty motors for precision, absolute encoders for positioning, and full bridge walkways for operator safety.

Key Considerations When Selecting Cranes Used For Power Plants

Choosing the right crane is a complex puzzle. It’s not just about lifting capacity; we work with clients to create custom solutions for their specific challenges.

- Load capacity is the starting point, ranging from small hoists to massive 1,000-ton cranes.

- Lifting height and radius are crucial, as the geometry of the lift is as important as the weight.

- Site access and ground conditions are critical, as power plants often have limited space and challenging terrain.

- Project timeline is another complexity, especially during outages where crane setup and disassembly must be rapid yet safe.

- Environmental factors like dust, humidity, or ice must be considered, and we select equipment designed to handle these conditions.

Our Crane Engineering Solutions help us tackle these complex requirements systematically.

The Importance of Expert Rigging and Lift Planning

Expert rigging and lift planning are what separate professionals from amateurs. We use advanced 3D lift planning software to simulate every lift, which eliminates surprises and minimizes risks. Our load calculations are comprehensive, accounting for rigging gear, wind, and dynamic forces. Our certified riggers create custom rigging design plans to ensure loads are secure and balanced, especially for valuable components. Certified signalpersons provide the critical communication link between operators and ground crews.

Our commitment to Crane and Rigging Safety drives everything we do. Our Rigging Services Pennsylvania demonstrate our dedication to safe and efficient lifting operations across our service area. When power plants need lifting solutions, they need partners who understand that precision and safety are non-negotiable.

Frequently Asked Questions about Cranes in the Power Sector

With three decades in the power industry, I’ve heard many questions about Cranes Used For Power Plants. Here are answers to the most common ones we encounter when planning lifts in our service area.

What are the most common types of cranes used for power plants?

The most common types include:

- Crawler cranes: The heavy lifters for major jobs like setting reactor vessels or boiler sections.

- Overhead and gantry cranes: Indoor workhorses for precise lifts in turbine halls and handling massive intake gates at hydroelectric dams.

- Tower cranes: Ideal for tall structures like cooling towers and large solar installations.

- Mobile cranes: Versatile problem-solvers for maintenance outages that require speed and adaptability.

- Polar cranes: Specialized cranes for nuclear plants with single-failure-proof systems for critical tasks like fuel handling.

How do you ensure safety when operating cranes near live power lines?

Safety is our top priority. It starts with our people—all our operators are NCCCO Certified Crane Operators with extensive experience. We use load-bearing insulators on the load line as a key defense against electrocution. Before any lift, we conduct site assessments and create detailed lift plans to identify all electrical hazards. Meticulous planning is key; we follow strict OSHA guidelines and coordinate with utilities to de-energize lines when possible. Our goal is that everyone goes home safe, and we maintain a zero-incident record by never cutting corners.

What is a “critical lift” in a power plant context?

A critical lift is a high-stakes operation where failure would have severe consequences, requiring meticulous planning. In power plants, this often involves:

- Extremely heavy or irreplaceable components, like a 335-ton turbine rotor, where a mistake could cause millions in damage and months of downtime.

- Lifting reactor vessels in nuclear plants, which are unique, multi-million dollar components requiring extraordinary precision and redundant safety systems.

- Complex maneuvers, like steering a transformer core through tight spaces, which require 3D lift planning and specialized rigging.

The financial stakes are enormous, as each day of an outage costs hundreds of thousands in lost revenue. Critical lifts demand exceptional expertise, planning, and backup systems.

Conclusion: Your Partner in Power Generation Lifting

When families across America flip on their lights, they rely on an invisible network of Cranes Used For Power Plants. From massive construction cranes to precise maintenance cranes, these machines are the unsung heroes keeping our energy flowing. The energy sector is the lifeblood of modern life, and we take our responsibility in supporting it seriously.

At Sky Point Crane, we’ve been part of this industry for decades. While lifting technology, efficiency demands, and reliability standards have evolved, our commitment to getting the job done right has not. We understand that power plants operate on tight schedules and budgets. During planned outages, there’s no room for failure. That’s why our NCCCO certified operators, with over 15 years of experience, bring critical precision to every project.

We are positioned throughout Western and Central Pennsylvania, Ohio, West Virginia, and Maryland to provide immediate lifting solutions. Our 24/7 availability is a core part of our service, building lasting relationships with energy companies who count on us.

Our comprehensive approach sets us apart. With 3D lift planning and detailed project management, every lift is thoroughly planned. We make challenging lifts possible because we know keeping America’s lights on depends on it. Our safety protocols are non-negotiable. In an industry where one mistake can cause massive outages, we are proud of our zero-incident track record. Every safety measure matters when the stakes are this high.

Whether you’re constructing a new facility, managing a critical outage, or planning a major modernization project, Sky Point Crane brings the expertise and equipment you need. We’ve handled everything from delicate turbine maintenance to massive component installations, and we’re ready to tackle whatever challenge your next project presents.

For comprehensive lifting solutions custom to the power generation industry, explore the markets we serve. When America needs power, we’re here to help make it happen.