Why Equipment Relocation Services Are Critical for Project Success

Equipment relocation services are specialized solutions for moving heavy machinery and critical business assets. Essential for facility moves, expansions, or upgrades, these services cover everything from planning and dismantling to transportation and reinstallation. A professional service includes:

- Planning & Assessment: Site surveys and detailed project logistics.

- De-installation & Re-installation: Safe disconnection, dismantling, reassembly, and testing.

- Custom Crating & Rigging: Specialized packaging and lifting for sensitive equipment.

- Transportation: Specialized hauling with air-ride trailers and climate control.

- Project Management: Single-source coordination from start to finish.

Moving industrial equipment is a high-stakes operation. A single mistake can lead to damaged machinery, extended downtime, or safety incidents. That’s why industries from manufacturing to healthcare rely on professional equipment relocation services instead of attempting complex moves in-house. The difference between a smooth transition and a costly disaster lies in expertise, specialized equipment, and meticulous planning.

I’m Dave Brocious, and with over 30 years in the energy and industrial sectors, I’ve seen how vital professional relocation is to business continuity. At Sky Point Crane, we solve complex relocation challenges with certified operators, advanced 3D lift planning, and a safety-first approach. This guide will cover everything you need to know about choosing the right partner for your project.

Equipment relocation services definitions:

Understanding the Scope of Equipment Relocation Services

When your business needs to move vital machinery, you need a partner who can handle the entire job. Equipment relocation services provide turnkey solutions with end-to-end support, allowing you to focus on your business while experts manage the move. From site assessment to final setup, professional project management ensures a seamless process. At Sky Point Crane, we offer comprehensive Equipment Moving Solutions custom to your needs, whether you’re moving a single machine or an entire facility.

What Do These Services Entail?

Professional equipment relocation services are a carefully orchestrated process:

- De-installation: Technicians safely disconnect and dismantle equipment, following strict safety protocols.

- Match-marking: Every component is labeled and documented to ensure perfect reassembly.

- Custom Crating: Sensitive or fragile equipment is protected with custom-built crates, shrink wrapping, and padding.

- Rigging: Specialized equipment like cranes and hydraulic gantries are used to safely lift and move heavy machinery. Our Full Service Heavy Lift Transport Solutions ensure precision and safety.

- Transportation: Specialized vehicles, including air-ride trailers, transport equipment safely. We handle all route planning and permits for oversized loads.

- Re-installation: Equipment is reassembled, reconnected, and positioned according to manufacturer specifications.

- Leveling and Alignment: Final calibrations are made to ensure machinery operates correctly and efficiently.

What Types of Equipment Can Be Relocated?

If it’s heavy, delicate, or critical to your operations, it can be relocated. We handle a diverse range of equipment, including:

- Manufacturing Machinery: CNC machines, injection molding equipment, printing presses, and entire assembly lines.

- Medical Equipment: MRI machines, CT scanners, and X-ray units that require exceptional care and precise calibration.

- Laboratory Instruments: Delicate microscopes and complex analytical systems, often requiring strict environmental controls.

- IT & Data Center Equipment: Server racks and critical infrastructure where minimizing downtime is paramount.

- Industrial Components: HVAC units, power generation turbines, and generators.

Which Industries Commonly Use These Services?

Nearly any industry with specialized equipment will eventually need professional equipment relocation services. We frequently serve:

- Manufacturing: Automotive, aerospace, and general fabrication plants moving production lines or upgrading equipment.

- Aerospace and Automotive: Industries using highly specialized production and testing machinery.

- Medical and Pharmaceutical: Hospitals, clinics, and labs with strict regulations and zero tolerance for equipment damage.

- Energy: Our team has extensive experience with Crane and Rigging in the Natural Gas Industry, serving power plants and renewable energy installations.

- Data Centers: High-stakes relocations where we help with Building Data Centers and moving critical infrastructure smoothly.

- Production and Processing: Food and beverage, chemical processing, and other operations with large-scale equipment.

The Strategic Advantages of Hiring Professionals

Attempting to relocate complex equipment in-house often leads to extended downtime, safety incidents, and unexpected costs. Smart businesses treat equipment relocation services as a strategic investment, not an expense. It’s about entrusting critical machinery to trained experts with the right tools and experience.

How Professionals Help Minimize Business Downtime

Every hour of downtime costs money. Professional equipment relocation services are designed to get you back up and running as quickly as possible through:

- Strategic Planning: Experienced project managers map out every detail, identify potential bottlenecks, and create contingency plans.

- Phased Moves: We can sequence the work to keep parts of your operation running, minimizing the impact on overall production.

- Efficient Execution: A professional crew with the right equipment can complete a move in days, not weeks. This Efficient Project Management approach gets you back to business faster.

- Turnkey Solutions: A single point of contact for the entire project eliminates coordination headaches and ensures clear responsibility.

This allows you to focus on running your business while experts handle the move. Our approach to Maximizing Efficiency on Site: The Role of Truck Crane Rentals in Project Management shows how the right resources keep projects on schedule.

Ensuring Safety and Mitigating Risk

Moving heavy machinery is inherently dangerous. Professionals mitigate these risks with a level of expertise that’s impossible to replicate in-house. Our crews do this every day and know how to handle challenges safely.

- Certified Personnel: Our teams include NCCCO certified crane operators and certified riggers who understand load dynamics, rigging mathematics, and safety protocols. Learn more about The Importance of Certified Riggers in Today’s Construction Industry.

- Regulatory Compliance: We follow strict Crane Safety Standards and OSHA requirements on every job, developing site-specific safety plans for each project.

- Specialized Equipment: Professional-grade cranes, rigging hardware, and transport vehicles reduce the risks associated with improvised solutions.

- Insurance Coverage: Reputable providers carry comprehensive insurance to protect your assets in case of an unexpected event.

The bottom line is that professional services dramatically reduce the risk of injury and damage, a benefit that often justifies the cost on its own.

Access to Specialized Equipment and Expertise

Most companies don’t own the specialized tools needed for a complex equipment move, nor do they have the expertise to use them. Professional equipment relocation services provide both.

We bring Specialized Lifting Equipment like hydraulic gantries, versatile Mobile Crane units, and air-ride trailers that protect sensitive equipment during transport. But the real value is the expertise to use these tools effectively. Our teams have years of hands-on experience moving everything from delicate medical devices to massive industrial presses. When you hire professionals, you’re not just renting equipment—you’re buying decades of accumulated knowledge and problem-solving ability.

The Anatomy of a Relocation Project

Understanding how an equipment relocation services project unfolds can explain the process. At Sky Point Crane, our refined Crane Project Management approach guides you from the initial conversation to the final commissioning of your equipment.

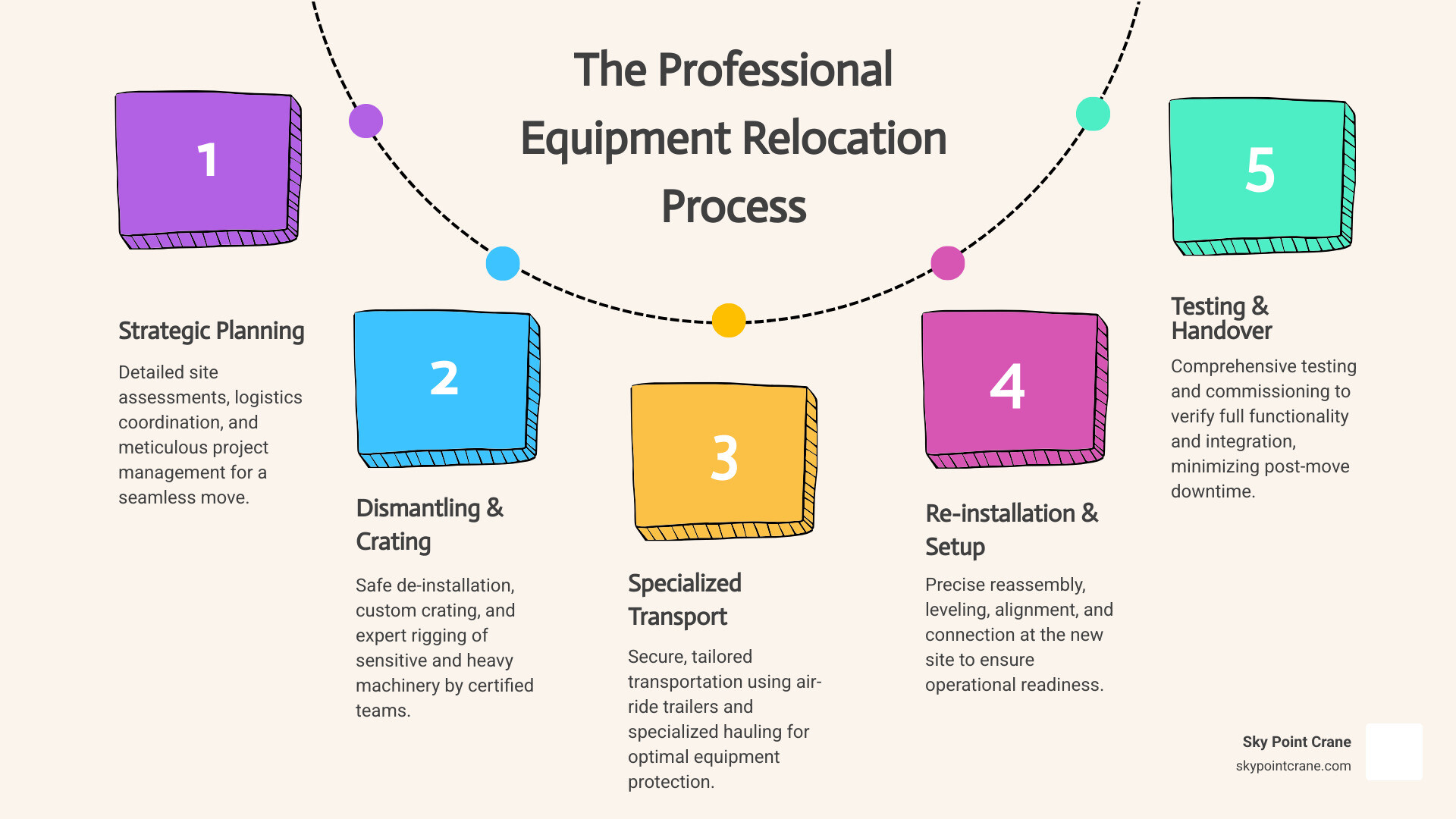

The Step-by-Step Relocation Process

Every successful project follows a proven roadmap:

- Pre-Move Planning & Site Assessment: We walk both your current and new facilities to measure access points, check floor loads, and identify potential obstacles. This detailed groundwork is central to our Construction Project Management approach.

- Logistics Coordination: We map transportation routes, secure necessary permits, and schedule all crews and equipment.

- Dismantling & Packing: Our teams carefully disconnect utilities, match-mark all components, and use custom crating for sensitive equipment.

- Transportation: Your assets travel in specialized vehicles, such as air-ride trailers, with GPS tracking available for high-value items.

- Unpacking & Reassembly: We methodically reassemble your equipment at the new site, following our detailed documentation and manufacturer specifications.

- Testing & Commissioning: We perform final leveling, alignment, and operational tests to ensure your equipment is ready to produce.

Single Piece vs. Entire Plant Relocation

Moving a single machine is very different from relocating an entire facility. While both require expertise, the scale and complexity increase exponentially with a full plant move.

- Single Piece Move: The focus is on one asset, with a project timeline measured in days. Downtime is limited to that specific machine.

- Full Plant Relocation: This is a massive undertaking involving interconnected production lines and support systems. Planning is extensive, often phased to maintain partial production, and requires coordinating dozens of specialists over weeks or months.

This level of complexity demands dedicated project management with deep experience in industrial relocations.

The Critical Role of De-installation and Re-installation

Properly de-installing and re-installing complex industrial equipment is where technical expertise truly matters. Our turnkey services handle both ends of the move with equal care.

During de-installation, technicians carefully disconnect mechanical, hydraulic, and electrical systems, documenting everything for a seamless re-installation. We often coordinate with Original Equipment Manufacturers (OEMs) to ensure compliance with their specifications, especially for equipment under warranty.

Re-installation is more than just reconnecting parts. The equipment must be leveled and aligned to precise specifications and tested thoroughly. Our Rigging Services Pennsylvania are designed to deliver this level of precision. The ultimate goal is operational readiness, ensuring your machinery performs exactly as it did before the move.

Modern Technology and Safety in Equipment Relocation Services

The field of equipment relocation services has been transformed by technology, making complex moves safer, more efficient, and more predictable than ever before.

The Role of Technology in Modern Relocation

Instead of guesswork, we use cutting-edge tools to ensure precision and safety.

- 3D Lift Planning: We use software to simulate every aspect of a complex lift before a crane arrives on site. This allows us to identify and solve potential issues in a virtual environment. Learn more about 3D Lift Planning: The Future of Crane Operations.

- Project Management Software: This technology keeps everyone on the same page, providing real-time updates and seamless coordination.

- GPS Tracking: Provides peace of mind by allowing you to know the exact location of your assets during transport.

These tools are integrated into our Crane Engineering Solutions, giving us capabilities that were impossible a generation ago.

Essential Safety and Security Protocols

Technology is only as good as the safety protocols behind it. We approach safety as a comprehensive system.

Our commitment to Crane and Rigging Safety is foundational. Every project begins with a safety briefing, equipment inspection, and a site-specific safety plan that meets or exceeds OSHA requirements. We protect your equipment with custom crating, air-ride suspension on transport vehicles to absorb shocks, and climate-controlled transport for sensitive items. This is all backed by comprehensive insurance coverage and executed by certified personnel who adhere to our strict Crane Safety Protocols.

How Companies Handle International Equipment Relocation Services

While Sky Point Crane focuses on Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, it’s useful to understand the added complexity of international moves. These projects involve navigating customs and documentation, coordinating with international logistics partners, and complying with different countries’ regulations. This global perspective highlights the specialized nature of equipment relocation, where meticulous planning and expert execution are paramount, whether moving across town or across continents.

Choosing Your Relocation Partner and Understanding Costs

Selecting the right partner and understanding the costs are practical steps to ensure your project runs smoothly and stays on budget. Your due diligence here is critical.

Factors to Consider When Choosing a Provider

You’re entrusting a provider with critical business assets. Look for:

- Experience and Reputation: How long have they been in business? Do they have a proven track record with projects like yours?

- Safety Record: Ask about their safety record and commitment to ongoing training. A strong safety culture is non-negotiable.

- Certifications: Ensure their operators are NCCCO certified. These certifications represent proven competency.

- Equipment Fleet: Do they have the right tools for your specific job, from specialized lifting gear to climate-controlled transport?

- Project Management: A dedicated project manager who serves as a single point of contact is invaluable.

- Insurance: Confirm they carry comprehensive insurance that covers your equipment throughout the entire process.

At Sky Point Crane, our NCCCO certified operators and robust safety culture meet these criteria for projects across our service area.

How Relocation Costs Are Quoted

Cost is important, but understanding how equipment relocation services are priced helps you budget effectively. Key factors influencing a quote include:

- Equipment Size and Weight: Heavier, larger equipment requires more specialized gear.

- Distance and Complexity: Cross-state moves or intricate machinery with precise alignment needs increase costs.

- Labor Requirements: The number of riggers, operators, and other specialists needed.

- Permits and Logistics: Oversized loads require route surveys, permits, and escort vehicles.

- Additional Services: Custom crating, warehousing, or reassembly will be included.

A reputable provider will conduct a detailed site survey and provide a transparent, itemized quote. The lowest price isn’t always the best value—prioritize experience and safety. You can Request a Quote from us for detailed, transparent pricing.

Additional Services to Look For

The best providers offer more than just the core move. Look for supplementary services like:

- Industrial Storage: Secure Industrial Storage provides flexibility if your new facility isn’t ready.

- Scrap Removal: A convenient service to dispose of old equipment and materials. We offer Scrap Removal to streamline your project.

- Millwright Services: Skilled craftspeople for precision alignment, maintenance, and fabrication work during re-installation.

Frequently Asked Questions about Equipment Relocation

Businesses planning a major equipment move often have similar questions. Here are answers to the most common concerns about equipment relocation services:

How do you ensure the safety of my equipment during the move?

We protect your assets through a multi-layered approach. It starts with expert planning, including 3D lift planning to simulate the move and identify risks beforehand. Our teams consist of highly trained, NCCCO Certified Crane Operator Jobs personnel who understand the nuances of handling heavy, sensitive machinery. For transport, we use specialized equipment like air-ride trucks to absorb shocks and can provide custom crating for extra protection. We adhere to strict Crane Safety Protocols, maintain full OSHA compliance, and carry comprehensive insurance to protect your investment.

Can you handle both the de-installation and re-installation?

Yes. We offer true turnkey solutions that cover the entire process. Our skilled technicians handle the mechanical and electrical de-installation, carefully match-marking every component for accurate reassembly. At the new location, we manage the re-installation, including precise leveling and alignment. We can also coordinate with original equipment manufacturers (OEMs) to ensure every step meets factory specifications. Our goal is to make your equipment fully operational in its new home, minimizing your downtime.

What is the difference between relocating a single machine and an entire plant?

The difference is scale and complexity. Moving a single machine is a focused project with a timeline of hours or days, impacting only one part of your operation. A full plant relocation is an exponentially more complex undertaking, involving dozens or hundreds of interconnected machines and systems. It requires extensive Rigging Project Management and is often executed in phases to keep some production lines running. The coordination involves numerous specialists and a timeline measured in weeks or months, making it a massive logistical challenge that demands deep experience.

Conclusion

Moving critical equipment is about protecting your investments and ensuring business continuity. Professional equipment relocation services deliver on three key promises: improved safety, operational efficiency, and minimized downtime. By partnering with experienced professionals, you gain access to certified operators, specialized equipment, and comprehensive project management.

From 3D lift planning to final commissioning, every step is designed to protect your assets. The right partner is crucial for success. For complex projects in Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, a partner like Sky Point Crane provides the expertise and advanced tools necessary for a smooth transition.

We understand that every project is unique. We invite you to explore the markets we serve and contact us to discuss your specific needs. Let us show you how expert equipment relocation services can turn a stressful move into a seamless project that keeps your business on track.