Why Industrial Storage Solutions Drive Project Success

Industrial storage solutions are the backbone of efficient warehouse and facility operations, encompassing everything from basic pallet racking to advanced automated systems. These solutions optimize space utilization, boost productivity, and ensure safe storage of materials across diverse industries.

Key Types of Industrial Storage Solutions:

- Pallet Racking Systems – Adjustable, drive-in, push-back, and flow racking for palletized loads

- Manual Load Systems – Longspan shelving, multi-tier systems, and carton flow for smaller items

- High-Density Solutions – Mobile racking and compact systems that maximize space efficiency

- Automated Systems – AS/RS, shuttle systems, and miniload for high-volume operations

- Specialized Structures – Clad-rack warehouses and vertical lift modules

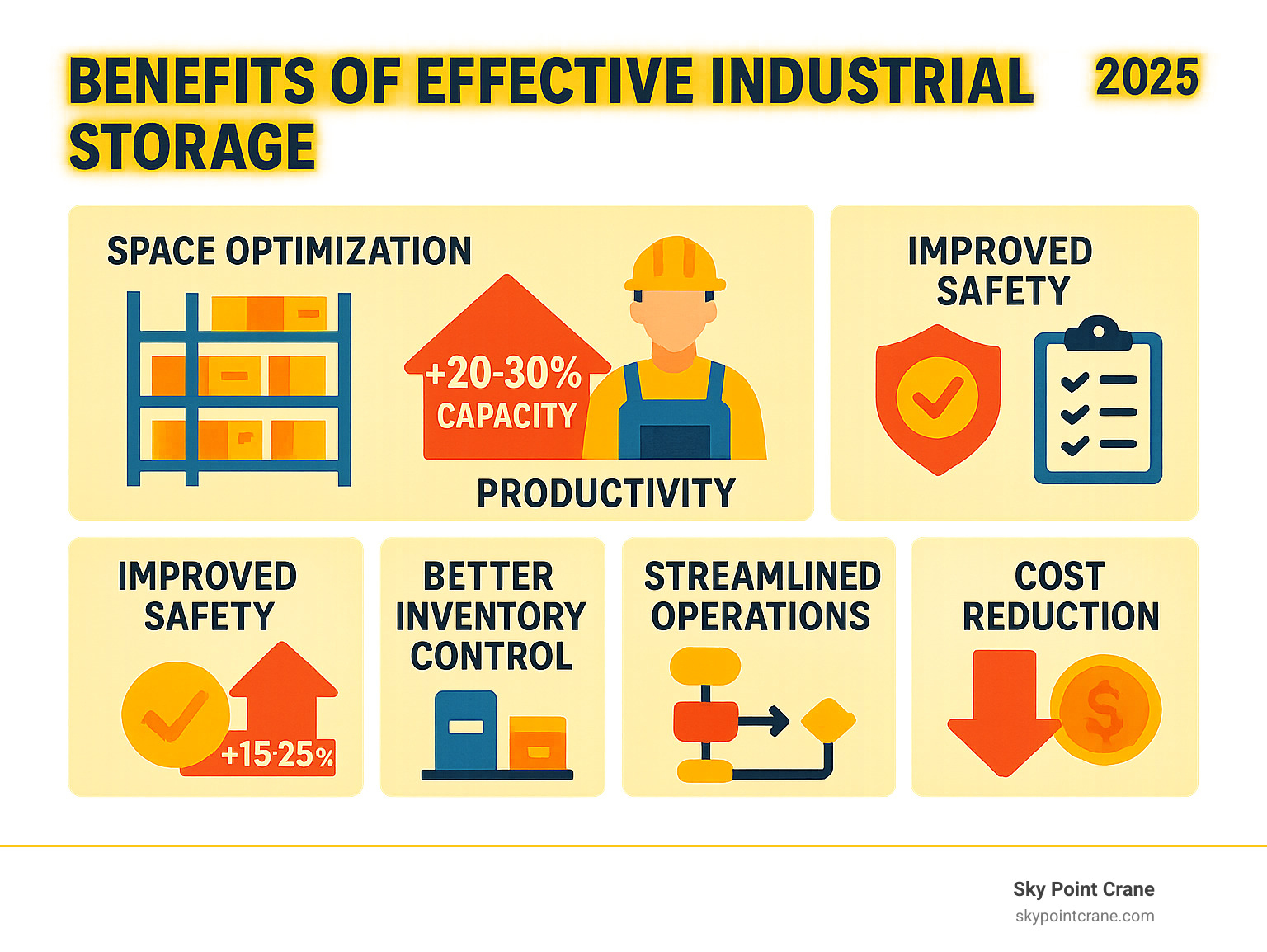

The global industrial storage systems market is experiencing significant growth, valued at $11.5 billion in 2023 and projected to reach $17.8 billion by 2030. This expansion is driven by e-commerce growth, supply chain optimization needs, and the demand for automated solutions that can improve warehouse productivity by 15-25% while increasing storage capacity by 20-30%.

Modern facilities face mounting pressure to maximize efficiency in increasingly constrained spaces. Whether you’re managing construction materials, manufacturing components, or distribution inventory, the right storage system can transform your operational capabilities. From basic selective racking that provides direct access to every pallet, to sophisticated automated retrieval systems that operate around the clock, today’s industrial storage solutions offer unprecedented flexibility and performance.

I’m Dave Brocious, and with over 30 years of experience in strategy, manufacturing, and distribution management, I’ve seen how the right industrial storage solutions can make or break project efficiency. Through my work with Sky Point Crane, I help construction and industrial clients optimize their facilities with comprehensive storage, rigging, and material handling solutions.

The Core Benefits of Strategic Industrial Storage

When you think about what makes an industrial operation truly successful, it’s not just the flashy equipment or the latest technology. It’s the foundation – and that foundation is smart storage. Industrial storage solutions do so much more than just hold your stuff. They’re the silent workhorses that maximize your space, keep your team safe, streamline your workflows, and ultimately put money back in your pocket.

The beauty of a well-designed storage system lies in its ability to handle the complete lifecycle of your materials. From the moment goods arrive at your dock to when they’re dispatched to their final destination, every step becomes smoother and more efficient. It’s like having a well-orchestrated symphony where every instrument knows exactly when to play.

Maximizing Your Facility’s Footprint

Let’s talk about one of my favorite topics – getting more bang for your square footage buck. Every facility manager I’ve worked with faces the same challenge: how do you fit more inventory without knocking down walls or signing a lease for additional space?

The answer lies in thinking vertically and getting creative with your layout. When we properly design industrial storage solutions with vertical space utilization in mind, the results can be remarkable. We’re talking about a 20-30% increase in storage capacity without expanding your building’s footprint. That’s like finding hidden treasure in your own warehouse!

Smart aisle configuration plays a huge role too. By optimizing how your aisles are laid out and choosing the right equipment to steer them, you can dramatically improve your storage density. It’s not just about cramming more stuff in – it’s about creating a system that makes sense for your specific operation.

Here in Western Pennsylvania, Ohio, West Virginia, and Maryland, where every square foot of industrial space comes at a premium, this kind of optimization isn’t just nice to have – it’s essential. For detailed strategies on making the most of your internal storage areas, check out our comprehensive guide on indoor industrial storage.

Boosting Operational Productivity and Safety

Now, here’s where things get really exciting. A well-planned storage system doesn’t just hold your inventory – it transforms how your entire operation functions. We consistently see productivity improvements of 15-25% when facilities implement the right storage solutions.

Think about it: when your team knows exactly where everything is and can access it quickly, magic happens. Reduced handling times mean faster order fulfillment. Streamlined picking processes mean fewer errors and happier customers. Your people spend less time hunting for items and more time adding real value to your operation.

But productivity means nothing if it comes at the cost of safety – and that’s where proper industrial storage solutions really shine. Good storage design creates natural safety barriers. Clear aisles mean fewer accidents. Proper load placement reduces the risk of items falling. Ergonomic considerations built into the system design help prevent workplace injuries before they happen.

Safety isn’t just about compliance (though we absolutely follow Material Handling Industry (MHI) standards). It’s about creating an environment where your team can do their best work without worry. When people feel safe, they’re more productive, more engaged, and more likely to stick around.

Key safety features we always emphasize include pallet rack post protectors that guard against damaging impacts, wire mesh decking that prevents items from falling through rack levels, proper load stops that maintain safe spacing, flue space dividers that ensure fire safety compliance, and professionally installed anchors that keep everything rock-solid stable.

The bottom line? Smart storage isn’t an expense – it’s an investment that pays dividends in space efficiency, operational speed, and peace of mind. And in my experience, that’s a combination that’s hard to beat.

A Guide to Non-Automated Industrial Storage Solutions

Not every operation needs the bells and whistles of full automation. Sometimes, the most effective approach is a well-designed non-automated system that delivers outstanding performance without the complexity. These industrial storage solutions rely on manual operation or standard material handling equipment like forklifts, and they’ve been the backbone of successful warehouses for decades.

When we’re planning these systems, we think about two main considerations: what type of loads you’re storing and how you need to access them. Palletized loads typically require different solutions than manual loads, and there’s always that fundamental trade-off between direct access and compact storage. Direct access systems let you reach any item immediately, while compact systems pack more into less space by sacrificing some of that instant accessibility.

Systems for Direct Access and High Selectivity

If your operation thrives on being able to grab any product at any time, direct access systems are your best friend. Think of them as the difference between a well-organized toolbox where every tool has its place, versus a storage shed where you might need to move things around to reach what you want.

Adjustable pallet racking is the workhorse of the warehouse world, and for good reason. It’s incredibly flexible – you can adjust beam heights as your inventory changes, store different sized pallets, and access every single pallet directly. This load flexibility makes it perfect for facilities with diverse product lines or high turnover rates.

Double-deep racking takes that concept and adds a clever twist. Instead of storing pallets one deep, you store them two deep on either side of the aisle. Yes, you’ll need a reach truck to get to that back pallet, but you’ve just significantly increased your storage density while maintaining good selectivity. It’s like having your cake and eating it too – more storage without completely giving up easy access.

For those really looking to maximize their vertical space, Very Narrow Aisle (VNA) racking is brilliant. We’re talking aisles as narrow as 5 feet! Special VNA forklifts steer these tight spaces with precision, allowing you to fit more racking rows in the same footprint. It requires specific equipment and careful planning, but the payoff in increased capacity can be substantial.

High-Density Compact Storage Systems

When space is your most precious commodity, compact storage systems deliver impressive results. These industrial storage solutions prioritize fitting the maximum amount of product into the available space, often by eliminating traditional aisles.

Drive-in racking is perfect for storing large quantities of the same product. Forklifts literally drive into the racking structure, placing pallets deep within the system. It’s incredibly space-efficient for bulk storage, especially when you’re dealing with seasonal items or products with lower turnover rates.

Push-back racking operates on a LIFO (Last-In, First-Out) principle. Each new pallet pushes the previous ones back on inclined rails or carts. When you remove the front pallet, the next one rolls forward automatically. It’s like having a self-organizing storage system that maximizes density while keeping everything accessible from a single aisle.

Pallet flow racking uses gravity to create a FIFO (First-In, First-Out) system. Pallets roll down gentle inclines on rollers from the loading side to the picking side. This ensures proper product rotation – crucial for perishable goods or items with expiration dates.

Mobile racking might be the cleverest space-saver of all. Entire rows of racking mount on mobile bases that move along floor rails. Instead of multiple permanent aisles, you only need one working aisle at any time. This can recover up to 50% of your floor space – imagine doubling your storage capacity without expanding your building!

For operations that extend beyond indoor facilities, our outdoor industrial storage solutions provide robust options for materials that can withstand the elements.

Solutions for Manual Handling and Lighter Loads

Not everything comes on a pallet, and that’s where specialized shelving systems shine. These solutions are designed for small parts organization and order picking efficiency, making manual operations smooth and productive.

Longspan shelving handles those medium to heavy items that don’t fit neatly on pallets. Think automotive parts, construction materials, or bulk goods that need to be accessed by hand. These systems offer wide bays and deep shelves with excellent flexibility for irregularly shaped items.

Multi-tier shelving is like building a second (or third) floor inside your warehouse. These systems create liftd walkways and additional storage levels, effectively multiplying your storage space vertically. It’s particularly valuable for lighter items where you can safely add levels without overloading your floor.

Carton flow systems bring gravity to work for smaller items. Cartons or totes flow from the loading side to the picking side on inclined rollers, ensuring automatic product rotation and reducing travel time for order pickers. It’s especially effective in e-commerce and distribution centers where speed and accuracy in small item picking can make or break your operation.

The beauty of these non-automated industrial storage solutions lies in their proven reliability, flexibility, and cost-effectiveness. They grow with your business, adapt to changing needs, and deliver solid performance day after day. Sometimes, the best technology is the one that simply works.

The Rise of Automated and Specialized Structures

The future of warehousing is here, and it’s pretty exciting! As businesses face increasing pressure to move faster and handle more volume, automation has become a game-changer in industrial storage solutions. These cutting-edge systems use robotics and smart software to handle materials with minimal human involvement, creating what many call the “warehouse of the future.”

Think of it this way: while traditional warehouses rely heavily on human workers to move, sort, and retrieve items, automated systems work around the clock with precision that would make a Swiss watchmaker jealous. For high-volume operations, this technology isn’t just nice to have – it’s becoming essential for staying competitive.

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems, or AS/RS for short, represent the pinnacle of warehouse innovation. These systems are designed for lightning-fast, high-density storage and retrieval that can dramatically reduce labor costs while boosting throughput to levels that would be impossible with manual operations.

The beauty of AS/RS lies in its versatility. AS/RS for pallets uses massive stacker cranes and automated mechanisms to handle full pallets in towering racking structures. Picture a giant robot arm that never gets tired, working with surgical precision to move heavy pallets exactly where they need to go. These systems are perfect for operations that need to store and retrieve entire pallets quickly and efficiently, maximizing both space utilization and throughput.

On the lighter side, miniload systems handle the smaller stuff – cartons, totes, and trays that don’t require the heavy-duty approach of pallet systems. These specialized AS/RS units bring products directly to human pickers, eliminating the time workers spend walking around the warehouse looking for items. It’s like having a personal assistant that fetches exactly what you need, when you need it.

Shuttle systems take automation to another level entirely. These systems use automated shuttle carts that zip around inside racking lanes, moving pallets with impressive speed and efficiency. Think of them as high-tech trains running on tracks within your storage racks, dramatically increasing both storage capacity and operational speed. They’re particularly effective in high-density, high-throughput environments where every minute counts.

Clad-Rack Warehouses: The Ultimate in Space Integration

Now, here’s where things get really interesting. Clad-rack warehouses completely flip the traditional warehouse concept on its head. Instead of building a warehouse and then installing storage racks inside it, the racking system becomes the building structure itself.

In a clad-rack design, the structural racking doesn’t just hold your inventory – it supports the walls, roof, and withstands external forces like wind and snow loads. It’s architectural engineering at its finest, creating a building integration that’s both neat and incredibly efficient.

This approach offers some remarkable advantages. Maximized height is perhaps the most obvious benefit – these structures can soar much higher than conventional buildings, giving you massive storage capacity on a relatively small footprint. The reduced construction time is another huge plus, since you’re essentially building the structure and storage system simultaneously rather than in separate phases.

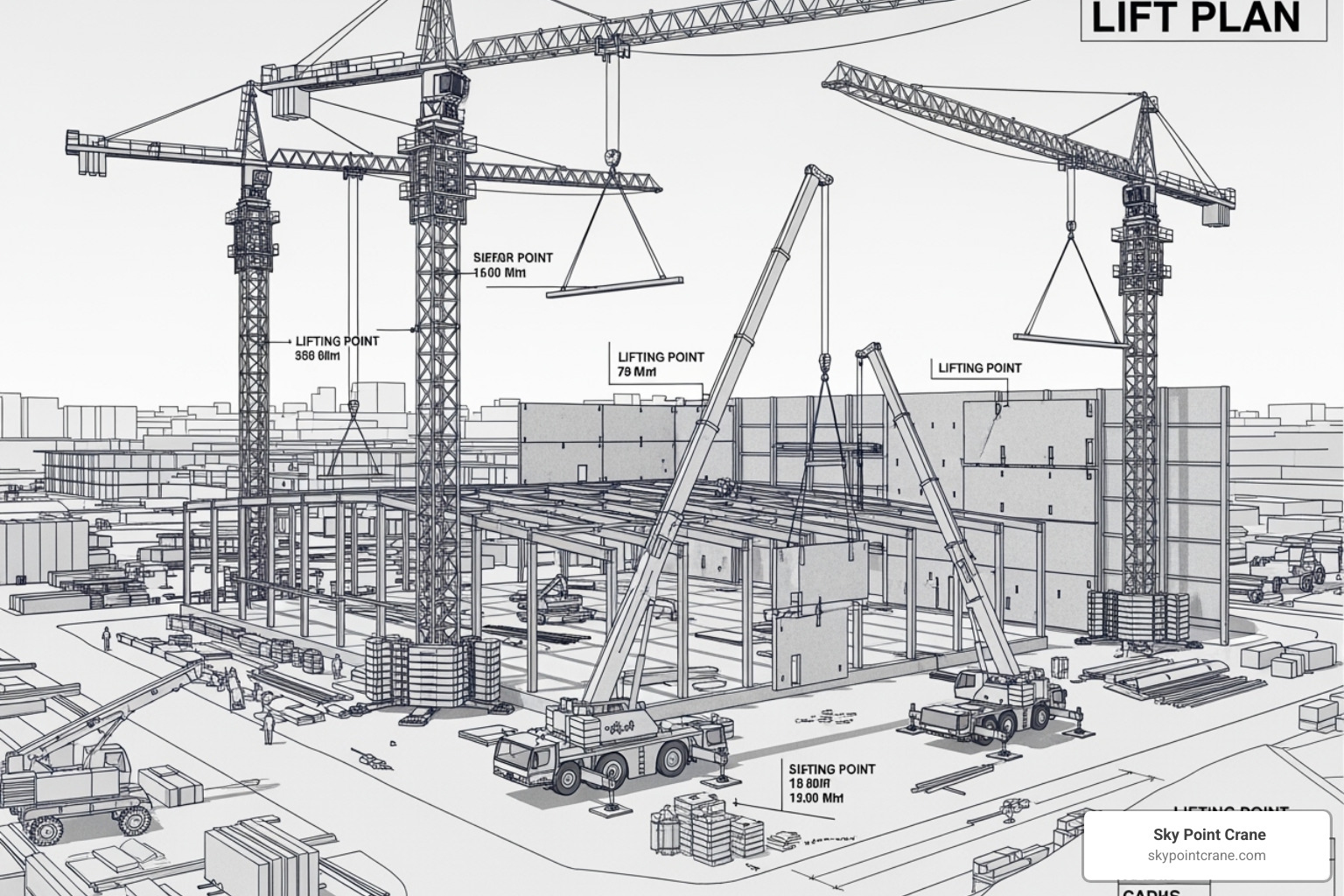

At Sky Point Crane, we understand the precision required for these complex installations. Our expertise in crane rental for steel erection makes us the perfect partner for getting these massive, integrated racking components positioned safely and accurately. After all, when your storage system is your building, there’s no room for error in the installation process.

The differences between traditional and clad-rack warehouses are pretty striking:

| Feature | Traditional Warehouse | Clad-Rack Warehouse |

|---|---|---|

| Structure | Building built first, then racking installed inside. | Racking is the primary structure; building enclosures are attached to it. |

| Height | Limited by conventional building methods. | Can be built to much greater heights, maximizing vertical space. |

| Cost | Separate costs for building and racking. | Integrated design can lead to overall cost savings due to less material and time. |

| Construction | Two distinct phases. | Integrated, often faster construction. |

| Flexibility | More flexible for reconfiguring internal layout. | Less flexible for internal layout changes once built. |

| Space Use | Can have wasted space between building and racking. | Optimizes space to the fullest, as racking is the building. |

While clad-rack warehouses offer less flexibility for future layout changes, they deliver best efficiency in space utilization. It’s the ultimate commitment to maximizing your storage potential – and when done right, it’s absolutely brilliant.

How to Select and Implement the Right System

Choosing the right industrial storage solutions is a critical decision that impacts efficiency, safety, and profitability for years to come. It’s not a one-size-fits-all scenario; what works for one industry or facility might be entirely unsuitable for another. A thoughtful approach to project planning and implementation is key to ensuring a successful outcome and a strong return on investment (ROI).

Key Criteria for Choosing Your Industrial Storage Solutions

When we’re helping our clients in Pittsburgh, Western Pennsylvania, Ohio, West Virginia, and Maryland evaluate their options, we always start with understanding what they’re actually storing. Product characteristics form the foundation of every decision – are we talking about palletized goods, loose materials, small components, or bulky items? The size, weight, and fragility of your products will immediately narrow down your options and point us toward the most suitable systems.

Inventory turnover tells us how your products move through the facility. If you need rapid access to every single item, we’re looking at high-selectivity systems like adjustable pallet racking. But if you’re storing large quantities of the same product that moves more slowly, high-density solutions like drive-in racking might be your best bet. This is where the FIFO versus LIFO question becomes crucial for your operation.

Your available space – particularly that often-overlooked vertical dimension – presents both opportunities and constraints. We’ve seen facilities double their storage capacity simply by maximizing their ceiling height with the right racking system. It’s amazing how much potential storage lives above our heads!

The handling equipment you currently use (or are willing to invest in) shapes everything else. Standard forklifts open up certain possibilities, while specialized equipment like VNA trucks or reach trucks open up even more space-efficient options. We always consider what makes sense for your current operations versus what might be worth upgrading.

Budget considerations go beyond just the initial investment. While some advanced systems cost more upfront, they often deliver significant long-term savings through reduced labor costs and increased efficiency. We help our clients see the complete picture when evaluating their options.

Scalability is something we never overlook. Your business will grow and change, and your storage system should be able to adapt alongside it. The best systems are flexible enough to accommodate new product lines or increased volume without requiring a complete overhaul.

We’ve seen remarkable results across various industries. One fire equipment company increased their storage capacity from 1,500 to 2,640 pallets in the same 1,200 square meter space using adjustable pallet racking. A paper products firm in Portugal built a 34-meter-high clad-rack structure that stores over 27,000 pallets while resisting harsh environmental conditions. These success stories show that the right system is always a custom solution custom to specific needs.

Ensuring a Successful Implementation

Once we’ve identified the perfect system for your operation, the real work begins. A thorough site assessment comes first – we need to understand your facility’s structural integrity, floor conditions, and how materials currently flow through your space. This groundwork prevents costly surprises later in the process.

System design is where engineering expertise meets operational reality. Our team creates customized layouts that optimize every square foot while ensuring smooth workflow and complete safety compliance. We’re not just designing storage; we’re designing efficiency.

Professional installation is absolutely critical, and it’s where our expertise at Sky Point Crane truly shines. Proper installation determines whether your system will be safe, durable, and perform as designed for decades to come. Large-scale racking installations require specialized equipment and skilled personnel who understand the precision required.

For complex structures and heavy racking components, our Heavy duty crane rental services ensure every piece is lifted and positioned with absolute precision. Our NCCCO certified operators bring the expertise needed to handle these critical installations safely and efficiently.

Project management keeps everything coordinated and on track. A dedicated project manager oversees the entire process, managing timelines, coordinating logistics, and maintaining clear communication with everyone involved. This single point of contact eliminates confusion and ensures nothing falls through the cracks.

Throughout every phase, safety protocols remain our top priority. We follow strict industry standards and regulations, maintaining the same unwavering commitment to safety that defines all our crane and rigging operations. After all, a successful installation is only successful if everyone goes home safely at the end of each day.

The implementation phase sets the stage for years of efficient operation. When done right, it transforms your facility into a well-oiled machine that supports your business goals and growth plans. When done wrong, it creates headaches that can last for years. That’s why we take such care to get every detail right from the very beginning.

Conclusion

When I look back at over three decades in manufacturing and distribution, I can tell you that effective industrial storage solutions aren’t just about storing stuff – they’re the secret sauce that transforms good operations into great ones. These systems serve as a strategic asset that drives efficiency and becomes the foundation upon which project success is built.

Think about it: when your storage system is working perfectly, everything else falls into place. Your team moves faster because they know exactly where to find what they need. Your facility feels spacious even when it’s packed to capacity. Most importantly, everyone goes home safe at the end of the day because everything has its proper place.

The numbers don’t lie either. We’ve seen facilities increase their storage capacity by 20-30% and boost productivity by 15-25% simply by implementing the right storage strategy. That’s not just moving boxes around – that’s changing your entire operation’s potential.

Whether you’re dealing with palletized loads that need quick access through adjustable pallet racking, or you’re maximizing every inch with high-density systems like drive-in racking or mobile storage, the key is finding that perfect match between your specific needs and the available solutions. Maybe you need the precision of an automated AS/RS system, or perhaps a straightforward longspan shelving setup will do the trick.

The beauty of modern industrial storage solutions lies in their adaptability. From traditional selective racking that gives you direct access to every pallet, to cutting-edge clad-rack warehouses where the storage system literally becomes the building itself, there’s a solution for every challenge and budget.

At Sky Point Crane, we’ve had the privilege of helping countless businesses across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland transform their storage capabilities. There’s something deeply satisfying about watching a well-planned storage system come together – seeing those massive racking components lifted into perfect position, knowing that this structure will serve our clients for decades to come.

Our NCCCO certified operators and precision lifting expertise ensure that your investment in storage infrastructure gets off to the right start. Because when you’re installing systems that might reach 30 feet high or more, there’s no room for error.

Ready to take your storage game to the next level? We’d love to show you how the right combination of smart storage design and expert installation can future-proof your operations for whatever comes next. Explore our industrial storage services and let’s start building something great together.