Why Used Industrial Shelving for Sale is Your Best Investment

Used industrial shelving for sale offers exceptional value for businesses seeking cost-effective storage solutions. Here’s what you need to know:

Key Benefits:

- Cost savings: 40-60% less than new equipment

- Immediate availability: No manufacturing lead times

- Proven durability: Cold-rolled steel construction tested in real-world conditions

- Environmental impact: Reduces waste and supports circular economy

Common Types Available:

- Steel shelving with clip or bolt assembly

- Boltless rivet shelving for easy installation

- Wire shelving for ventilation requirements

- Bulk rack and cantilever systems for specialized needs

Typical Pricing:

- Starter bays: $80-$150 per unit

- Standard dimensions: 18″ x 36″ or 24″ x 48″

- Heights: 6′ to 12′ (custom cutting available)

- Capacity: 400-800 lbs per shelf

The research shows thousands of bays of quality used industrial shelving are readily available, with major suppliers maintaining extensive inventories. As one customer noted: “We got a great deal on a very large order and I will definitely be back.”

I’m Dave Brocious, and with over 30 years of experience in manufacturing, distribution management, and solving complex industrial storage challenges, I understand how used industrial shelving for sale can transform your facility’s efficiency while protecting your bottom line. At Sky Point Crane, we’ve helped countless businesses optimize their storage solutions through strategic equipment selection and logistics expertise.

Handy used industrial shelving for sale terms:

The Unbeatable Benefits of Buying Used Industrial Shelving

When you’re setting up a warehouse or expanding your storage space, the choice between new and used equipment can feel overwhelming. But here’s what we’ve learned after years in the business: used industrial shelving for sale offers benefits that go far beyond just saving money. It’s about making smart decisions that help your business grow while doing right by the environment.

Why Second-Hand is a First-Rate Choice

Let’s talk numbers first, because they’re pretty impressive. When you choose used industrial shelving for sale, you’re looking at savings of 40% to 60% compared to buying new. That’s not pocket change – that’s serious money you can put back into your business. Maybe you need new equipment, want to hire another employee, or simply prefer keeping that cash in your operating account. Either way, you’re getting the same sturdy storage solution for nearly half the price.

The faster return on investment makes this choice even sweeter. Instead of waiting months or years to see your shelving investment pay off, you’re already ahead from day one. We’ve seen small businesses use these savings to compete with much larger companies, simply because they made smart purchasing decisions.

But there’s another side to this story that feels just as good – the environmental impact. When you buy used shelving, you’re giving perfectly good equipment a second life instead of sending it to a landfill. You’re also reducing the demand for new manufacturing, which means less energy consumption and fewer raw materials pulled from the earth. It’s what economists call a circular economy, and it’s a powerful way to reduce your business’s carbon footprint without sacrificing quality or performance.

For businesses looking to maximize their storage efficiency, our Commercial Storage Solutions can help you make the most of every square foot.

Immediate Availability and Proven Performance

Here’s something that might surprise you: used industrial shelving for sale is often ready to ship immediately. No waiting around for manufacturing schedules or dealing with supply chain delays. When your business needs storage solutions now, used equipment delivers. We’re talking about thousands of bays in stock and ready for immediate shipping – that’s the kind of availability that keeps your projects moving forward.

The durability factor is where used shelving really shines. This isn’t furniture that wears out after a few years. Industrial shelving is built from high-strength steel – specifically cold-rolled steel that’s designed to handle serious weight and constant use. When you buy used, you’re getting equipment that’s already proven itself in real-world conditions. It’s been tested by time, heavy loads, and daily operations.

Think about it this way: if that shelving has been holding up inventory for years and still looks solid, you know it’s going to keep performing. The high-quality materials used in industrial shelving mean that even after years of service, the structural integrity remains strong. You’re not buying someone else’s problem – you’re buying real-world tested equipment at a fraction of the cost.

Need additional storage options for tools and smaller items? Consider pairing your shelving with Industrial Cabinets for a complete storage system.

A Buyer’s Guide to Common Types of Used Industrial Shelving for Sale

Walking into a warehouse filled with different types of shelving can feel overwhelming, but here’s the good news: used industrial shelving for sale comes in predictable, well-designed categories that each serve specific purposes. Once you understand the basics, choosing the right system becomes much clearer.

Think of industrial shelving like building blocks – each type has its own assembly method and purpose. The beauty of buying used is that you can often find exactly what you need without waiting for custom orders or paying premium prices.

Steel, Rivet, and Boltless Shelving Explained

The world of industrial shelving revolves around three main assembly styles, and each has earned its place for good reasons.

Clip-style shelving uses small metal clips that slide into slots on the upright posts. It’s like a grown-up version of adjustable home shelving, but built to handle serious weight. The real advantage here is flexibility – you can move shelves up or down in seconds without any tools. Perfect for businesses where inventory sizes change frequently.

Nut and bolt assembly is exactly what it sounds like – traditional nuts and bolts holding everything together. While it takes longer to set up, this method creates an incredibly rigid structure. Think of it as the most permanent option, ideal for heavy-duty applications where you won’t be moving things around much.

Boltless rivet shelving has become incredibly popular because it combines strength with convenience. The shelves snap into place using a system of rivets and keyhole slots – no tools required. It’s strong enough for industrial use but easy enough that you won’t need a engineering degree to assemble it.

Now, regardless of which assembly method you choose, you’ll encounter two main structural approaches. Open shelving units use X-bracing or sway bracing for stability, leaving all sides accessible. This works great when you need to reach items from different directions. Closed shelving units include back and side panels that completely surround your stored items, protecting them from dust and providing extra structural support.

For businesses planning their Indoor Industrial Storage setup, understanding these differences helps ensure you get exactly what your space needs.

Specialized Shelving for Unique Needs

Beyond the standard options, used industrial shelving for sale includes specialized systems designed for specific challenges that every industry faces.

Bulk rack shelving and wide span shelving tackle the problem of storing large, awkward items that don’t fit on regular shelves. These systems feature longer spans (often 72″ to 96″ wide) and deeper shelves (24″ to 48″ deep), giving you the space needed for oversized inventory without wasting floor space.

Cantilever racks solve a completely different puzzle – how do you store long items like lumber, pipes, or steel bars? These ingenious systems use a central column with arms extending outward, creating unobstructed storage bays. No upright posts getting in your way when you’re trying to slide out a 20-foot piece of material.

Wire shelving brings a different set of advantages to the table. The open wire construction allows air to circulate freely, prevents dust from settling, and lets light pass through. It’s particularly valuable in food service, clean rooms, or any environment where hygiene and visibility matter.

For smaller items, bin shelving transforms standard shelving into organized storage for thousands of small parts. Think of auto parts stores or electronics suppliers – they need every bolt, screw, and component easily accessible but neatly organized.

Record archive storage addresses the reality that many businesses still need to store physical documents. These systems accommodate standard archive boxes efficiently, helping you manage vast quantities of paperwork without losing your sanity.

Whether you’re planning Outdoor Industrial Storage or need specialized indoor solutions, each of these shelving types serves a specific purpose. The key is matching your actual storage needs with the right system – something that becomes much more affordable when you choose quality used equipment.

Key Factors to Consider Before You Buy

Shopping for used industrial shelving for sale is a lot like buying a reliable used truck for your business. You want something that’s going to work hard, last long, and keep your operation running smoothly. The key is knowing what to look for and asking the right questions before you make your investment.

Assessing Condition, Lifespan, and Quality

When we evaluate used shelving, we’re looking beyond the sticker price to understand the real value. Think of it as getting under the hood to see what you’re really buying.

Visual inspection is your most powerful tool. Look closely at the uprights, shelves, and connections. Surface rust might look concerning, but it’s often just cosmetic and can be easily treated with a wire brush and some paint. What you really need to watch for is structural damage like severe dents, bent uprights, or deep pitting rust that could compromise the shelving’s strength.

Pay special attention to the welded corners on steel shelving. Quality units feature box-type adjustable shelves with lapped and welded corners. These aren’t just fancy details – they’re signs of robust construction that will stand up to years of heavy use.

Reputable brands like Lyon, Borroughs, and Penco have earned their reputation through decades of reliable performance. While brand isn’t everything, it’s often a good indicator of the quality you can expect. These manufacturers built their shelving to last, which is why you’ll find their products still going strong after 20 or 30 years of service.

Speaking of longevity, industrial shelving made from cold-rolled steel is built for the long haul. With proper care, used shelving can easily provide another decade or more of reliable service. The typical lifespan depends largely on how well it was maintained by its previous owner and the conditions it worked in.

Matching Shelving to Your Needs: Dimensions and Capacity

Getting the right fit isn’t just about finding shelving that looks good – it’s about ensuring safety and maximizing efficiency in your operation.

Common dimensions you’ll encounter are 18″ x 36″ and 24″ x 48″ for depth and width. These sizes have become standard because they work well for most storage needs. Heights typically range from 7′ to 12′, though some suppliers can cut uprights to custom heights if needed.

Weight capacity is where safety becomes critical. The steel gauge determines how much weight each shelf can handle safely. 18, 20, and 22 gauge steel are common, with lower numbers meaning thicker, stronger material. Most industrial shelving handles 400-800 lbs per shelf when the load is evenly distributed, but always verify the exact capacity with your supplier. Adhering to these limits is essential for maintaining a safe work environment, as outlined in OSHA’s guidelines for warehouse safety.

Here’s something many people don’t consider: employees sometimes step on the bottom shelf to reach higher items. That’s why we often recommend a heavier duty bottom shelf that can handle the extra stress.

Understanding starter vs. adder units can save you money and space. A starter unit stands alone with its own uprights, while adder units share uprights with existing units. This lets you create long runs of shelving efficiently and cost-effectively.

Getting the right shelving setup is crucial for any storage operation. Whether you’re planning a small workshop or a large distribution center, our team at Sky Point Crane understands how proper storage integrates with your overall operational efficiency. For businesses looking for flexible options, our Business Storage For Rent services can help you find the perfect storage solution.

Where to Find and How to Purchase Your Shelving

Once you’ve determined your needs, the next step is finding reputable sources for used industrial shelving for sale and understanding the purchasing process. Think of it as treasure hunting, but with better odds and less digging involved.

Finding Reputable Sellers of Used Industrial Shelving

The good news is that quality used industrial shelving for sale is more accessible than you might think. The key is knowing where to look and who to trust.

Material handling suppliers and warehouse equipment liquidators are your best starting points. These businesses make their living buying and selling warehouse equipment, so they understand quality and have reputations to protect. Many maintain inventories with thousands of bays of shelving in various conditions. Some even offer refurbished options that perform “as good as new” but at used prices.

What sets these suppliers apart is their expertise. They can help you understand the differences between brands, assess condition, and match equipment to your specific needs. Plus, they usually have established shipping networks, which is no small consideration when dealing with heavy steel equipment.

Sky Point Crane’s used inventory represents another valuable resource. While our primary focus is crane rental and rigging services across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland, our involvement in industrial projects means we often encounter or can source quality used shelving. We understand how storage integrates with the broader picture of facility efficiency and safety.

When we work with clients on comprehensive facility solutions, we sometimes identify opportunities to incorporate pre-owned equipment that delivers excellent value. Our network in the industrial sector can be particularly helpful if you’re looking to integrate shelving into a larger project or need guidance on optimizing your storage layout.

For personalized assistance or to explore what might be available through our network, reach out through Sky Point Crane’s contact page. We’re always happy to help connect you with the right solutions.

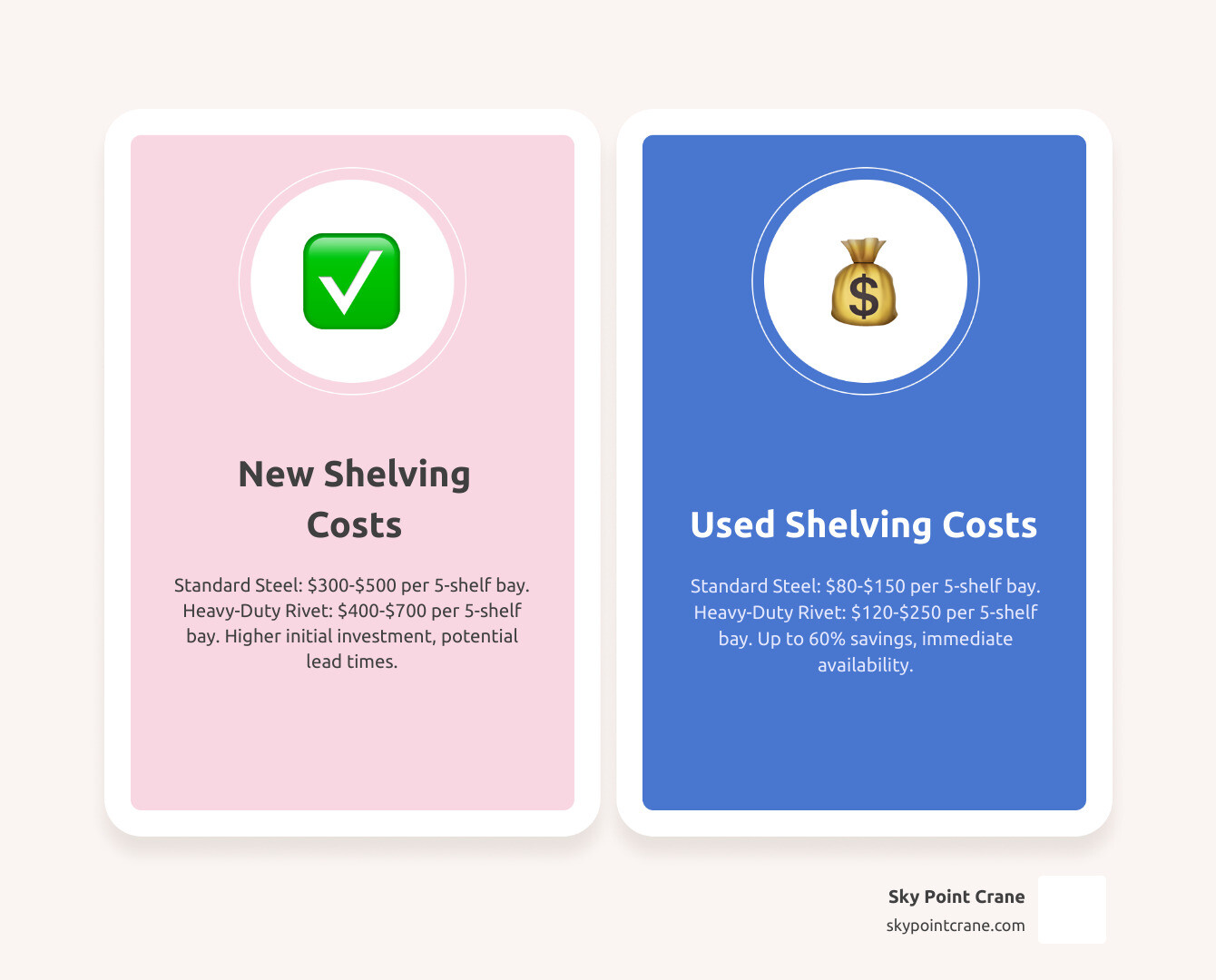

Comparing the Cost of Used Industrial Shelving

Here’s where the numbers get exciting. The cost savings with used industrial shelving are substantial enough to make even the most budget-conscious operations smile.

New versus used pricing tells a compelling story. A new industrial shelving bay can easily run several hundred dollars, while quality used starter bays typically range from $80 to $150. For example, a used industrial metal shelving starter bay measuring 18″ x 48″ x 85″ might cost around $116-$132. Compare that to the $300-$500 you’d pay for the same unit new, and the math becomes pretty straightforward.

Bulk purchase discounts make the deal even sweeter. Most suppliers offer better pricing when you’re outfitting an entire facility rather than buying a bay or two. This volume pricing can push your savings into truly significant territory.

Don’t forget to factor in shipping costs early in your planning. Industrial shelving is heavy and bulky, which means transportation isn’t cheap, especially over long distances. The good news is that many specialized suppliers have established shipping networks and can provide accurate quotes upfront. Always get shipping costs in writing before committing to a purchase.

Quote requests are your friend. Rather than guessing at final costs, most reputable suppliers offer fast quote services where you specify your needs and receive custom pricing. This approach ensures you’re comparing apples to apples when evaluating different suppliers.

The goal isn’t necessarily the lowest price, but the best value for your operational needs. This means balancing cost with condition, capacity, and the reputation of your supplier. A slightly higher price from a trusted source often pays dividends in quality, service, and peace of mind.

When you’re investing in used industrial shelving for sale, you’re not just buying storage equipment. You’re investing in operational efficiency, safety, and the flexibility to adapt as your business grows. The substantial cost savings simply make it easier to justify doing it right the first time.

Frequently Asked Questions about Used Industrial Shelving

When you’re considering used industrial shelving for sale, it’s natural to have questions. After decades in the industrial equipment world, we’ve heard them all! Let me share the answers to the most common concerns that come up when businesses are making this smart investment.

How much weight can used industrial shelving hold?

This is probably the most important question you can ask, and rightfully so. Safety comes first, always. The weight capacity of used industrial shelving isn’t a one-size-fits-all answer – it depends on several key factors that work together.

Steel gauge makes all the difference. The thickness of the steel directly impacts how much weight your shelves can handle. You’ll commonly see 18, 20, and 22 gauge steel options. Here’s the thing that surprises people: lower numbers mean thicker, stronger steel. So 18 gauge is actually stronger than 22 gauge.

Manufacturer quality matters too. Different brands build to different standards, and this shows in their load ratings. Reputable manufacturers like Lyon, Borroughs, and Penco have established reputations for robust construction that translates to higher weight capacities.

Shelf construction plays a huge role. Look for shelves with box-type construction and lapped, welded corners. These are significantly stronger than simple flanged edges. It’s one of those details that makes a real difference when you’re loading heavy items.

Most industrial shelving you’ll find can handle 400 to 800 pounds per shelf when the weight is evenly distributed. Heavy-duty options can go even higher. But here’s the catch – that “evenly distributed” part is crucial. If you pile all the weight in one corner, you’re asking for trouble.

Always ask the seller for specific capacity ratings, and if possible, try to find the original manufacturer specifications. When in doubt, err on the side of caution.

What’s the difference between open and closed shelving?

This choice often comes down to what you’re storing and how you plan to access it. Both types are sturdy and reliable, but they serve different purposes.

Open shelving units don’t have solid back or side panels. Instead, they use diagonal X-bracing (called sway bracing) to keep everything stable and rigid. The beauty of open shelving is that you can access your items from all four sides, which speeds up picking and organizing. Air flows freely through the unit, which is great if you’re storing items that need ventilation.

Closed shelving units come with full back and side panels that completely encapsulate your stored products. Think of them as protective boxes for your inventory. They shield everything from dust, debris, and accidental spills. Items can’t fall off the back or sides, and everything looks neat and organized.

If you’re storing archive boxes, sensitive components, or anything that needs protection from the elements, closed shelving is your friend. For general warehouse storage where you need quick access from multiple angles, open shelving often works better.

Can I customize used shelving?

Absolutely, and this is one of the best features of used industrial shelving for sale! Industrial shelving systems are designed to be modular and adaptable. We often help customers modify their used shelving to fit unique spaces or changing needs.

Height adjustments are straightforward. If you find shelving that’s taller than you need, the upright posts can usually be cut down to fit your space perfectly. Got 16-foot posts but only 8-foot ceilings? No problem.

Adding or removing shelves is easy. Most systems let you adjust shelf spacing or add extra shelves as your storage needs evolve. This flexibility is invaluable when your inventory changes or grows.

Mixing components works within limits. You can often combine shelves, posts, and clips from the same brand and style to create custom configurations. Just make sure you’re staying within the same product family – compatibility between different manufacturers can be tricky and might compromise safety.

Accessories expand your options. Dividers, bin fronts, and modular drawers can transform basic shelving into highly organized storage systems for small parts or specialized inventory.

The key is ensuring that any modifications maintain the structural integrity and safety of the system. When done right, customization helps you squeeze every bit of efficiency from your storage investment.

Conclusion

Making the decision to invest in used industrial shelving for sale isn’t just about saving money – though those 40-60% savings certainly don’t hurt! It’s about making a smart, forward-thinking choice that benefits your business, your budget, and the environment all at once.

Throughout this guide, we’ve shown you how used shelving delivers proven durability from cold-rolled steel construction, immediate availability without manufacturing delays, and environmental responsibility through the circular economy. Whether you need basic steel shelving, specialized cantilever racks, or anything in between, the used market offers incredible variety at unbeatable prices.

The secret to success lies in knowing what to look for. Inspect the condition carefully, match the dimensions and weight capacity to your specific needs, and work with reputable sellers who stand behind their products. Quality used shelving can serve you just as well as new equipment – sometimes for decades.

At Sky Point Crane, we’ve seen how the right storage solutions can transform a facility’s efficiency. While our bread and butter is crane services and rigging, our deep experience with industrial projects means we understand how storage infrastructure fits into the bigger picture. Our expertise in complex industrial storage and equipment logistics ensures your facility is set up for maximum efficiency and safety, whether you’re installing new systems or integrating quality used equipment.

We’ve helped countless businesses across Western and Central Pennsylvania, Ohio, West Virginia, and Maryland optimize their operations. Sometimes that means lifting equipment into place, other times it’s about understanding how all the pieces – including smart storage choices – work together.

Your facility deserves storage solutions that work as hard as you do. Used industrial shelving for sale offers the perfect combination of value, reliability, and environmental consciousness that today’s smart businesses demand.

Ready to optimize your space? Explore our comprehensive industrial storage solutions today!